What is the best and most accurate way to cut strips of styrene strips from sheets? Thanks.

Replies sorted oldest to newest

Off the top of my head: straight edge and an exacto-knife.

Yep. Straight edge and sharp blade are hard to beat. A couple of hints:

1) Get one of those self-healing cutting mats with a measurement grid on it.

2) Consider single-edge razor-blades rather than an Xacto-knife. If you buy in bulk, the blades are MUCH cheaper--enough so that you can more or less use a fresh blade every time, which makes a BIG difference for precision work. IMO this more than makes up for the slightly worse ergonomics.

Evergreen Scale models has a selection of styrene strips. Click on the underlined.

The first thing I would do is follow Mike CT's advice and check the Evergreen website and also the Plastruct website. You will almost never be able to slice your own strips, especially thin ones, with the consistency of the manufactured versions. I like Evergreen but Plastruct also has a large selection of strips. When checking out the sites, also look at the section for scale sized lumber strips, including strips for other scales. While these items are listed by scale size (say 2x4), the decimal equivalents are listed as well. I have often found that the scale size strips are close enough to what I need to avoid cutting strips off of a sheet.

If cutting your own, best methods depend somewhat on what thickness of styrene sheet you are cutting from, and what width of strips you are cutting. Thicker sheets are usually scored and snapped off, while thinner sheets can be cut through. The issue with scoring and snapping when cutting thin strips is getting leverage on both sides of the score to snap the piece off. It can be quite difficult to grip the thin side of the score. So it may be necessary to cut all the way through, even on thick sheet material. Of course the more cuts required, the more opportunity for a slip or inaccurate cut. I'm planning on checking into the type of pliers used to snap ceramic tile, which is also frequently "cut" using a score and snap method. I have seen pliers with wide flat jaws that grip along a long edge. I haven't yet tried this method so I can't speak to the results.

Regarding tools, you should use whichever knife or blade type you are most comfortable with, assuming it is sharp. Some people like scalpels, others x-acto knives, while some like the traditional razor blade. When cutting or scoring sheet, the blade will usually leave a raised edge along either side of the cut. Scalpels can somewhat minimize this due to their narrower edge. But this isn't a critical point. The raised lips can be removed quite easily with a quick scrape or sanding.

I prefer to use a metal straightedge designed for cutting as opposed to measuring. Many of these have a vertical ridge to protect finger tips from the blade should it ride up on top of the cutting edge.

No matter which type of cutting edge you choose, make sure it has a non-slip backing on the back side. This can be cork, or a strip of self adhesive non-slip material bought from Home Depot or Lowes. The non-slip material can usually be bought in various widths, and by the foot in length. Peel the backing and stick it to your cutting edge. You will be applying pressure to both the cutting edge and the blade. This feature will help keep the cutting edge where you want it, and also reduce the risk of the edge and blade slipping resulting in an injury.

I'm a big fan of not slicing into (or through) my fingers. I've nicked them plenty of times despite knowing better.

A lot of cutting tools and even the non-slip backing can be found in art supply stores, often in greater variety than what can be found at the big box home stores.

If you have any other questions, feel free to ask.

Jim

Attachments

Sir I bought A craft decorating cutter table for scrapbooking at A local craft store. it is plastic and kind of cheap but it has A cutter arm on one side and on the other side has A interchangeable cutter wheels. I use the straight cut wheel run it across the plastic A few times and it cuts right through the plastic. The table has measurements on it already. Say you are cutting 1/2 inch strips just square up one end of your material and keep moving it out 1/2 inch at A time. The arm that the cutter wheels run on locks down into place to hold down your material so you don't have to. Hope this might be something for you to consider and take care. Choo Choo Kenny![]()

What is the best and most accurate way to cut strips of styrene strips from sheets? Thanks.

How thick is the sheet material and how fine a strip off it do you want? Thin sheet material is relatively easy to cut using as sharp a blade as you are willing to handle against a good metal straightedge. Thicker stuff can be problematic to do accurately.

Buying as already noted is probably best and is what I do to avoid inaccuracies in cutting styrene.

I have to agree with MWB. I have been scratch building for over 25 years. Started out with wood then styrene plastic. for what it's worth, there is no better way than purchasing pre cut strips. Then cutting them with the Northwest Chopper II.

Safety meeting of the day. 90% of getting the job done correctly/safely is the right tool/s, edit add, right material. Be careful out there. ![]() Mike CT

Mike CT

Straight edge with grip-face...sharp blade, sharp blade, sharp blade...flat, flat, flat support surface...calm nerves...checking twice to be sure the pinkies/nails are clear of the cut line....steady, even pull/pressure on the knife/blade........box of Band-Aids handy.![]()

Buying Evergreen strip is definitely the way to go. Sometimes, tho', it's not worth an extra trip to the LHS for that last strip to finish a project step for the day/night when you have the correct thickness of sheet stock lying there. Been there.....faced that.

But, the biggest nuisance to cutting strips....IMHO...is the burr kicked up along the cut edge of the strip. Understand that when you 'cut' plastic, you're really only displacing it...sorta like a plow making a furrow in a field. The plastic must go somewhere. It does....forming a burr on either side along the cut edge.

Ergo, to have the appearance be consistent with the rest of your work, the burr has to go. But.....the smaller/thinner the strip, the more challenging it is to remove the burr cleanly. I use the edge of the same cutting blade (say, a #ll in a holder) drawn along the burred edge perpendicular to it. Another one of the practice-makes-easier techniques. Sandpaper, files, ....even thumbnails!!!....have been known to work. Besides, the use of the same #11 blade in removing the burr is what keeps Johnson&Johnson (Band-Aids) in business....IMHO, of course.![]()

Oh well, it's only free advice. The School-of-Hard-Knocks-and-Bloody-Digits is the other institution of painful learning for this sort of enigma.

FWIW, always....

KD![]()

........box of Band-Aids handy.![]()

Do not forget to keep that roll of adhesive tape in the shop and a few sterile pads, too, ![]() .

.

I prefer to use a metal straightedge designed for cutting as opposed to measuring. Many of these have a vertical ridge to protect finger tips from the blade should it ride up on top of the cutting edge.

Big Train

Where did you get that straightedge? Thanks.

Train Head if you have A machine shop close to you you could get A thin piece of sheet metal bent into A (L) shape or you could go to Lowes or Home Depo and buy A piece of angle iron for A straight edge. Choo Choo Kenny![]()

"The issue with scoring and snapping when cutting thin strips is getting leverage on both sides of the score to snap the piece off. It can be quite difficult to grip the thin side of the score. So it may be necessary to cut all the way through, even on thick sheet material. Of course the more cuts required, the more opportunity for a slip or inaccurate cut. I'm planning on checking into the type of pliers used to snap ceramic tile, which is also frequently "cut" using a score and snap method. I have seen pliers with wide flat jaws that grip along a long edge."

I have a couple of those wide nose pliers. One is the glass cutters type with about 3 inch jaws and one is a vicegrip type with a bit wider locking jaws. If the plastic sheet is wider than the pliers I clamp it in my wood worker's vise which has about 12 inch jaws. One might be able to make a saw cut in a piece of hard wood then stick the edge in there to break off the strips? For smoothing the edges don't forget the common carpenter's block plane, with a sharp blade they work great on plastic. I only make strips when I don't have the proper size of evergreen or plastruct material :>![]() ......DaveB

......DaveB

Big Train

Where did you get that straightedge? Thanks.

I'm pretty sure I got that one at Caboose Hobbies, conveniently and expensively located essentially down the street from me here in Denver. I can run by there and check today. Like many of this style, it is just an aluminum extrusion.

I know similar straightedges can be found online and in store at art supply houses and craft stores like Michaels. There is one at my local art supply store that is very nice and heavy duty compared to the one I have, but it is also expensive.

Jim

"The issue with scoring and snapping when cutting thin strips is getting leverage on both sides of the score to snap the piece off. It can be quite difficult to grip the thin side of the score. So it may be necessary to cut all the way through, even on thick sheet material. Of course the more cuts required, the more opportunity for a slip or inaccurate cut. I'm planning on checking into the type of pliers used to snap ceramic tile, which is also frequently "cut" using a score and snap method. I have seen pliers with wide flat jaws that grip along a long edge."

I have a couple of those wide nose pliers. One is the glass cutters type with about 3 inch jaws and one is a vicegrip type with a bit wider locking jaws. If the plastic sheet is wider than the pliers I clamp it in my wood worker's vise which has about 12 inch jaws. One might be able to make a saw cut in a piece of hard wood then stick the edge in there to break off the strips? For smoothing the edges don't forget the common carpenter's block plane, with a sharp blade they work great on plastic. I only make strips when I don't have the proper size of evergreen or plastruct material :>![]() ......DaveB

......DaveB

I'd love to have a bench vise. Even a small one. But seeing as my "bench" is my computer desk and de facto kitchen table, it could get tiresome moving a large one around.![]()

Jim

At a flea market, I picked up a little drill-press vise, kind of like this one:

Very useful. Precise and easy to move around.

These wide nose bending pliers are sheet metal working tools. I used them on a Mullet River model for bending. Not sure how well they would work on plastic.

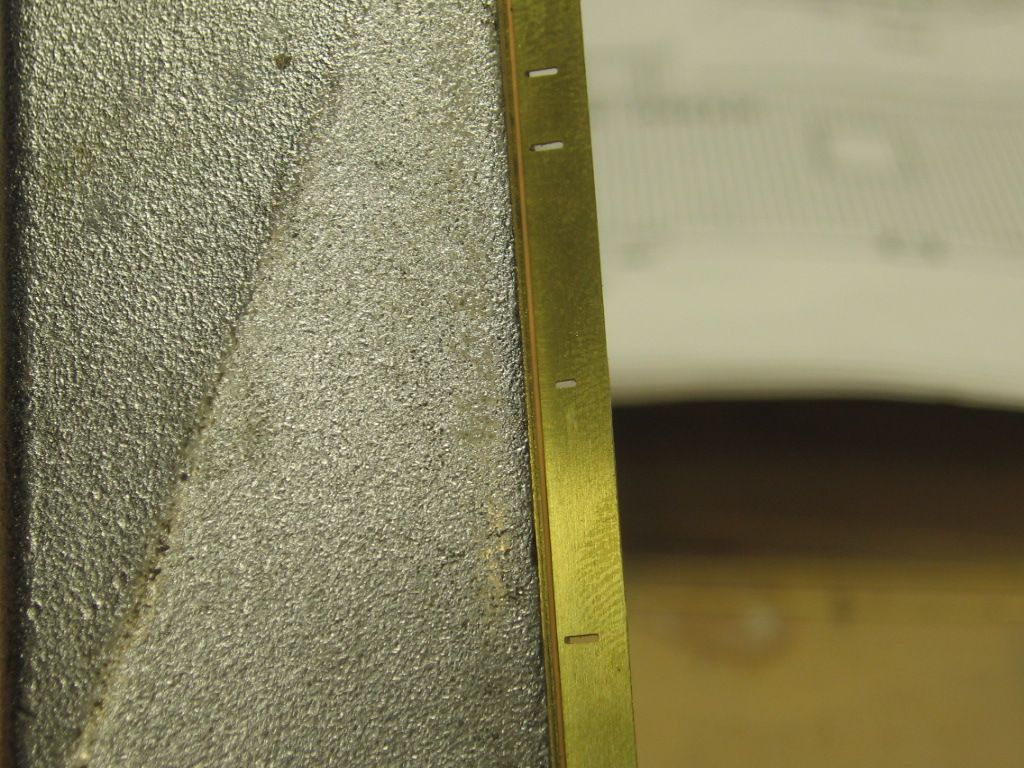

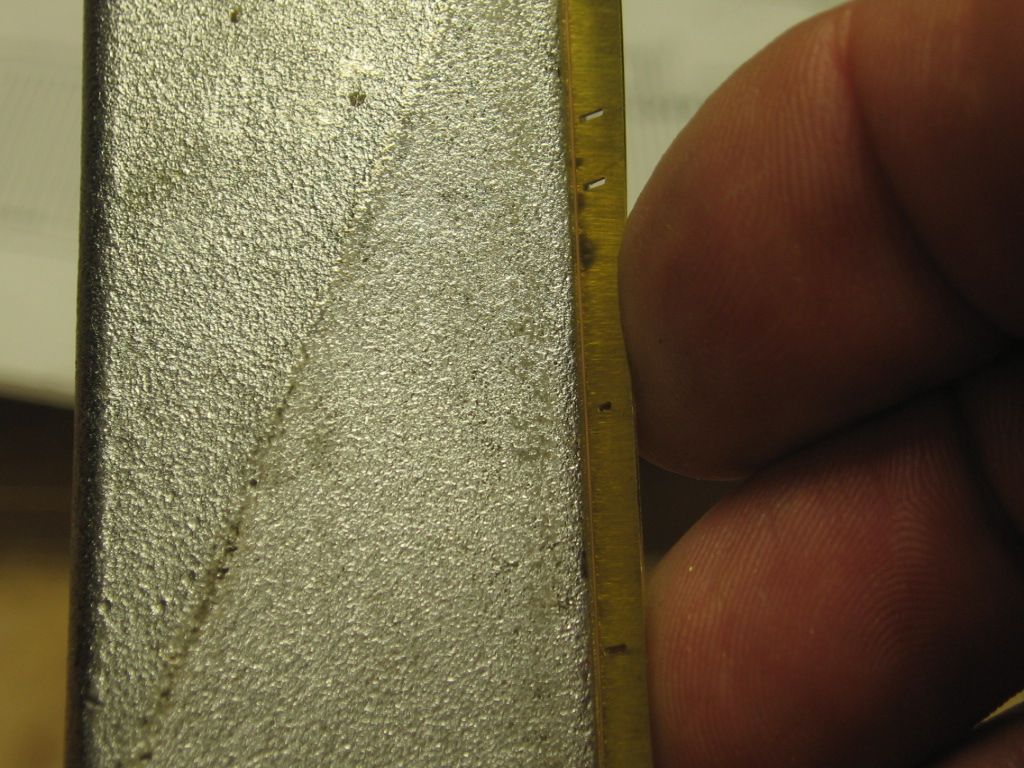

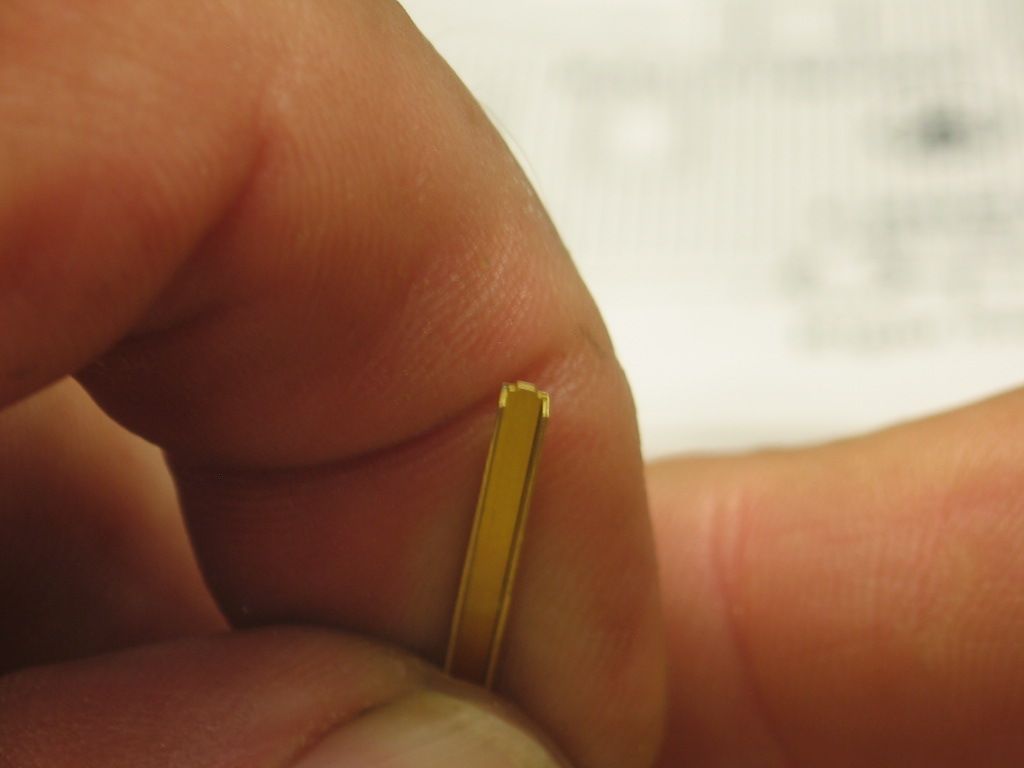

The straightedge shown in photos in my original post is a Micro-Mark tool. It is available on their website and also from Caboose Hobbies.

MicroMark 22 Inch T-bar Cutting Guide

Caboose Hobbies 22 Inch T-bar Cutting Guide

It's the same item available from either source. It does not have a non-slip backing so that will need to be applied. Non-slip tape can be found at Home Depot and I presume Lowes as well. Check in the paint department. It can also be found at the art supply store.

Here is a version from Alvin, which makes all kinds of drafting supplies. It's quite a bit more expensive.

There are others out there as well.

Jim

These wide nose bending pliers are sheet metal working tools. I used them on a Mullet River model for bending. Not sure how well they would work on plastic.

Thanks for that tip Mike. I'll check them out. Between pliers or a vise, I need to invest in a tool that can help me snap thin strips. Sooner or later I will need a piece that doesn't come in standard sizes.

Plus I just happen to have a Mullet River Central Vermont caboose kit sitting patiently in the pile of things to get around to someday.![]()

Jim

........box of Band-Aids handy.![]()

Do not forget to keep that roll of adhesive tape in the shop and a few sterile pads, too, ![]() .

.

Good grief! I almost forgot!!...(at my age!)....![]()

Keep a tourniquet handy!!![]()

...and a full bottle of CA labeled "FOR TRIAGE, ONLY!"![]()

![]()

KD![]()

A few more pictures. Tool pictured, is a duct work/ heating fabrication tool, (hand seamer) This one is a Malco S6.

Back to my original comment: Evergreen Scale models makes just about everything you would need in styrene strip plastic.

Back to my original comment: Evergreen Scale models makes just about everything you would need in styrene strip plastic.

Looks like a handy tool Mike.

As for straight edges, Harbor Freight has 12" stainless rules for 2 bucks. Longer ones for not a lot more.

Put me in the camp that would buy styrene strips if available rather than break them off a larger sheet.

Pete

Off the top of my head: straight edge and an exacto-knife.

Does anybody have the MicroMark Duplicate-It cutter. Do this tool work and is it worth the cost?