Thanks for all of the great information. I really appreciate it.

One thing I didn't make clear, is that as suggested by Leo, each separate power block will have several sets of 18 gauge wire feeders running to it, not just one. So, in each block, the load is spread among multiple sets of wires. And, at an absolute minimum, there will be one power feed for each 5 feet of track in a block.

Thanks for the info that at 8 feet, there is a 4% drop in voltage using the 18 gauge wire. But for me at least, that seems really really nominal. I tend to look at it from the other direction. I am getting at least 96% of the power to my tracks on the longest run of 8 feet. Most of the runs are much a much shorter distance than that. So, I feel that that is good enough for me.

Rich, I certainly respect your experience and opinions, and you have flatly stated that 18 gauge wire is not sufficient for long feeders. But so far, the data I am hearing from others doesn't seem to bear that out for the system I have proposed.

RJR, thanks for that very clear explanation of an alternative, more traditional way to wire the system. I really appreciate. Additional knowledge is always a good thing.

My goal is not to trick my transformer, or to turn track blocks on an off as the train moves around the layout. The only reason I would turn a block off is to "park a train" in that loop or straight-away, while I run another train. In other words, to use loops and straight-aways as "sidings". Why? Because the very original, eclectic layout I custom designed left no room for sidings. And, I can't park the trains in a traditional rail yard, because I just don't like using up the entire center of my layout to build a trainyard, or trying to back-up trains that may be parked there. (I'm really bad at backing up trains, especially over multiple switches.)

Except for a track block in which a train is parked, all of the other power blocks will be turned on all of the time.

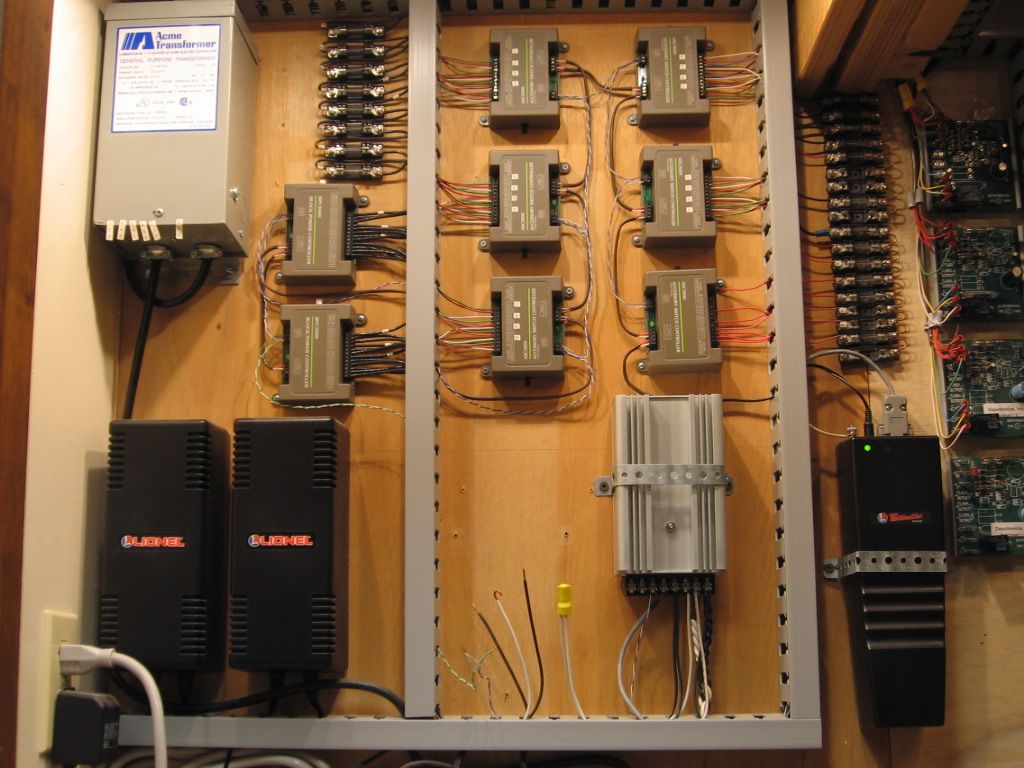

So, my real goal here is (i) to simply run sets of really easy-to-use 18 gauge feeder wires straight from the control box out to the tracks, with several feeders for each power block, thus doing away with heavy bus lines and taps, and (ii) eliminate the need to spend lots of time under the table.

Forgot to mention, that I have arthritis/tendonitis in my right hand so badly (carpentry and post hole digging), that it is really really painful me to try to work with heavy gauge wire, even trying to twist it with needle nose pliers.

With my proposed system, I would just drill a hole next to the tracks, drop two 18 gauge wires down the hole, reach under the table and pull the wires over to the control box on the other side of the table, , put the ends through the hole into the side of the control box, leaving two feet extra inside, hook them up in the box and then to the tracks, and then go under the table for 3 minutes and staple the wires in four or five places to the undersides of the table framework. Very easy. Done and done.

I am thought-checking this in advance, to make sure that the full load gets spread out among the feeders, and isn't through some electrical principle (I'm really dumb at this), still all get pulled through one set of wires.

What all of you have helped me realize by this great discussion, is that even if all of my power blocks are on, when a locomotive is traveling over a particular power block, the full load will only be spread out among the particular number of feeders that feed that particular power block, and not the other wires running to the powered blocks where no trains are traveling over them. And that is really something important for me to consider

Thanks,

Mannyrock