Quick question for those of you who have been working with Atlas lately, how is the connection with the joiners now? Are you getting good connections, signal ect with DCS/Legacy with out soldering or are you guys still soldering these. It is a permanent layout that is nice and level, so it will not be taken apart multiple times and such. Thanks all....![]()

Replies sorted oldest to newest

I am using the Atlas rail joiners with no soldering or jumper wires and it is all working just fine here. I have both DCS and Legacy and no problems with either system. I made sure the rail joiners were tight and was careful lining everything up when I laid the track and it all works very well.

N&W Class J posted:Quick question for those of you who have been working with Atlas lately, how is the connection with the joiners now? Are you getting good connections, signal ect with DCS/Legacy with out soldering or are you guys still soldering these. It is a permanent layout that is nice and level, so it will not be taken apart multiple times and such. Thanks all....

our club layout did not solder the joiners because they ran drops, lots of drops.

our club layout has been in operation since 2002, 6 days a week 5 hours a day.

a new layout in old town (built by our club members) soldered every joiner and has less drops.

there are no DCS or Legacy issues, on either layout.

make sure track is clean.

Ok, great information guys. Thanks so much.

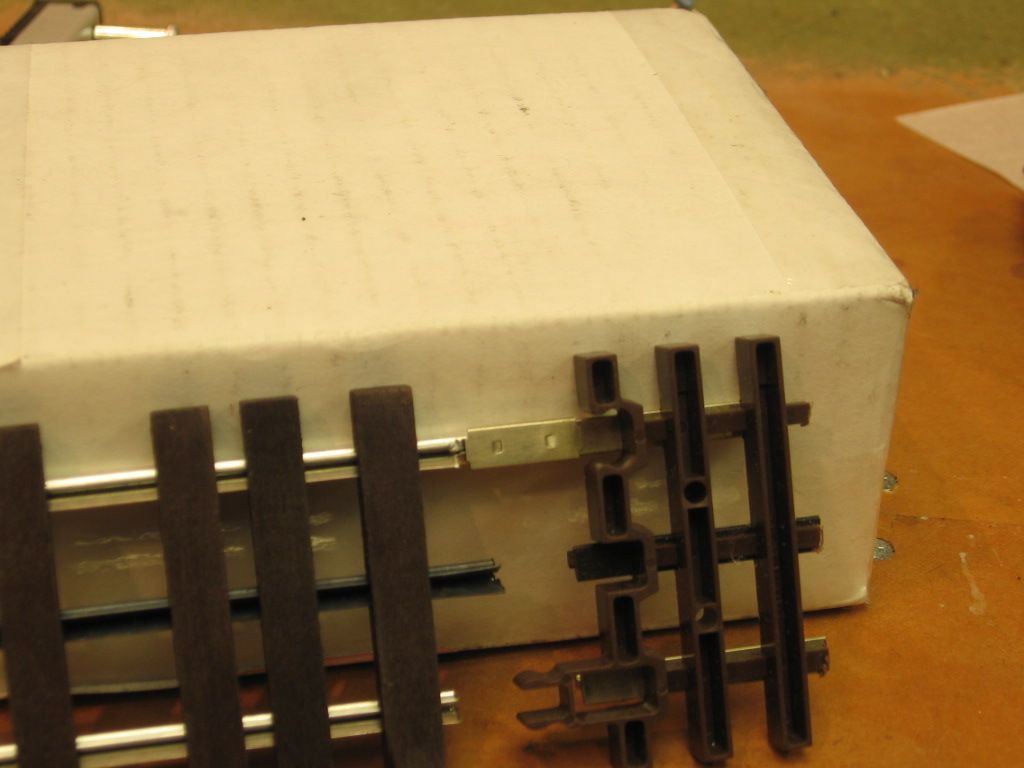

Recycled Atlas track and track parts should have a dimpled, indent in the bottom of the rail joiners. Also the rail joiner tension was improved to the point that installing the snap-together piece can be difficult. Note the indents bottom of the joiner. Atlas right, Gargrave track left, modified to work with Atlas.

Atlas sells the rail joiner separately.

Great photos, thank you sir. Yep what I'm working with has the dimples and does fit together very snugly.

I've been using Atlas O track on my permanent layout since 2004. I haven't had any problems with the track or DCS running through the track. The only issues that I had were with the switches. I figured out a very reliable way to fix the switches so I could have a strong signal (DCS) going through switches to my engines............rogerw.

For Rogerw -- Could you let us know your method of fixing the Atlas switches to ensure a strong DCS signal. If you have explained this before on the Forum, could you direct me to the thread. Thank you very much. I plan on having quite a few Atlas switches on my layout.

Steve

Yes what Steve said....what did you do?

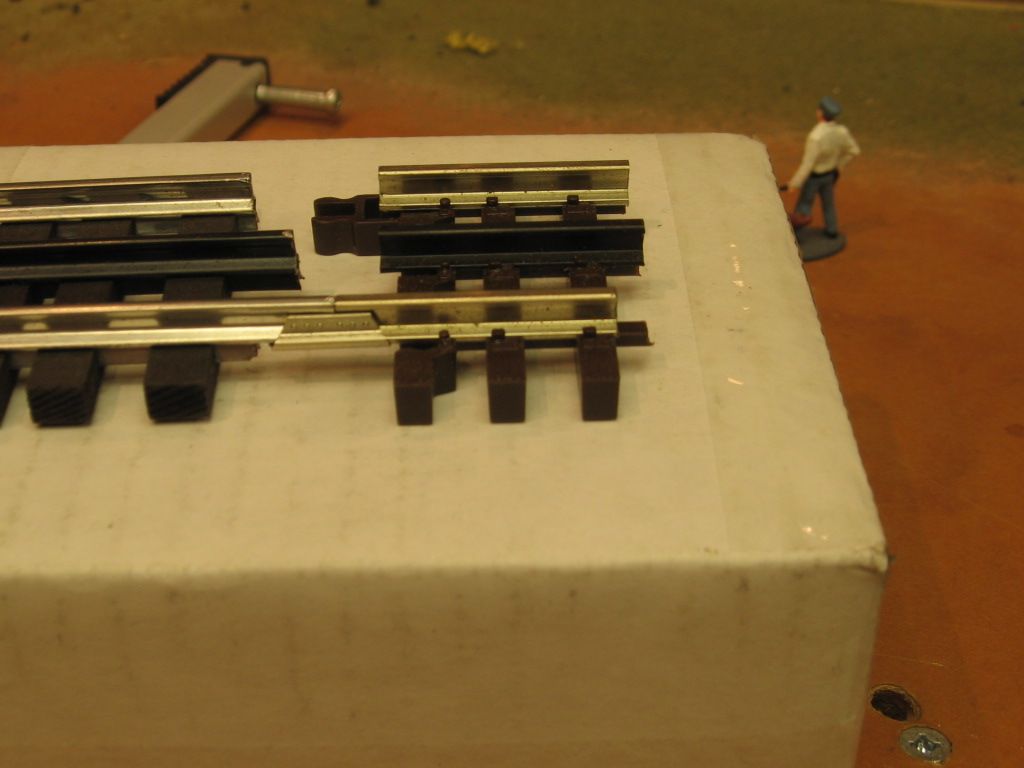

Hello PFERDDY, Here is a picture of the yard ladder on my layout. I have circled 3 switches that I put solder on to help with the DCS signal. When I purchased my switches, they have a very thin wire under them that was very inadequate for carrying 18-20 volts and the DCS signal. Where the circles are, I used a high powered solder gun to connect the gaps on the switch. I then sanded the solder joint down so my rollers on my engines wouldn't be bumping up and down. What I done to my switches doesn't destroy the switch and I haven't had ANY signal or power problems when running ANY of my engines through my switches......rogerw.

Attachments

For Rogerw -- Thank you very much, Roger. With your great photo, even I can understand your fix to the switches. I really appreciate your response. By the way, you have a beautiful layout.

Thanks again,

Steve