I spent a frustrating weekend installing Atlas non derail boards. I found they had a mind of their own, switching the turnouts at seemingly random times. They would be working as they should, but when I would run a train they would go amuck, switching to and fro. I had been powering five of them off my PWC ZW that the train blocks ran off. I guessed they did not have enough voltage to keep the relays closed or open. Had to run them off a PW ZW to give them enough voltage to get them to behave. They are good now. Has anyone experienced this issue, I am not good with electrical work, but always want to learn more. Fred

Replies sorted oldest to newest

Yes, Mine can be random related to overall power consumption on the layout. It appears to have a lot to do with the non-derail inputs from the isolated rail sections at the switches. Using the layout at a fixed 18 volts is very acceptable. Reduce Rail voltage or get into conventional use with TPC 400's and the random non-controlled switching greatly increases. I have 12 engines on the layout most of the time. Total track power is (2) parallel PH135's. Reducing the number of engines (on) seems to improve the problem. Keeping track voltage at or above 18 volts is best, which means I run TMCC all the time.

Keep in mind there are two power inputs to the boards. The power supply lower right and the Switch motor supply middle/upper left. Problem seems to be Switch motor supply power and maybe a problem with commons used to trip the relay boards either through or out. If I disconnect the isolated rail input and run with only TMCC ASC (Accessory Switch Control) inputs the system seems to work fine but I need the Iso rail non de-rail function for the logic to run power routing.

I felt all is wired well with 18 gauge solid thermostat wire and was surprised that this occurs. I basically work around the problem and have yet to address a correction.

You may want to contact Steve Horvath with Atlas about the problem. Phone: 908-687-9590

Mike, Thanks for the response and info. Your problems with these boards are the same issues I was dealing with. Very nice wiring in the photo! I may call Atlas, does seem the boards are fussy with their power needs. Fred

I have 12 engines on the layout most of the time. Total track power is (2) parallel PH135's. Reducing the number of engines (on) seems to improve the problem. Keeping track voltage at or above 18 volts is best, which means

I'm impressed that two 135W PowerHouse supplies work well for a dozen locomotives, how do you manage that? Are most of them idle?

It will run a fair load. This consist pushes 7 amps. Click on the image to access a 2.5 min video.

7A is about all you get from the 135W PowerHouse, I believe it's breaker will go much beyond that.

7A is about all you get from the 135W PowerHouse, I believe it's breaker will go much beyond that. At one time I could easily pop both resets at the same time on the Parallel PH 135's Since I installed the (8) inline 7.5 amp fuses I rarely need to reset the PH's.

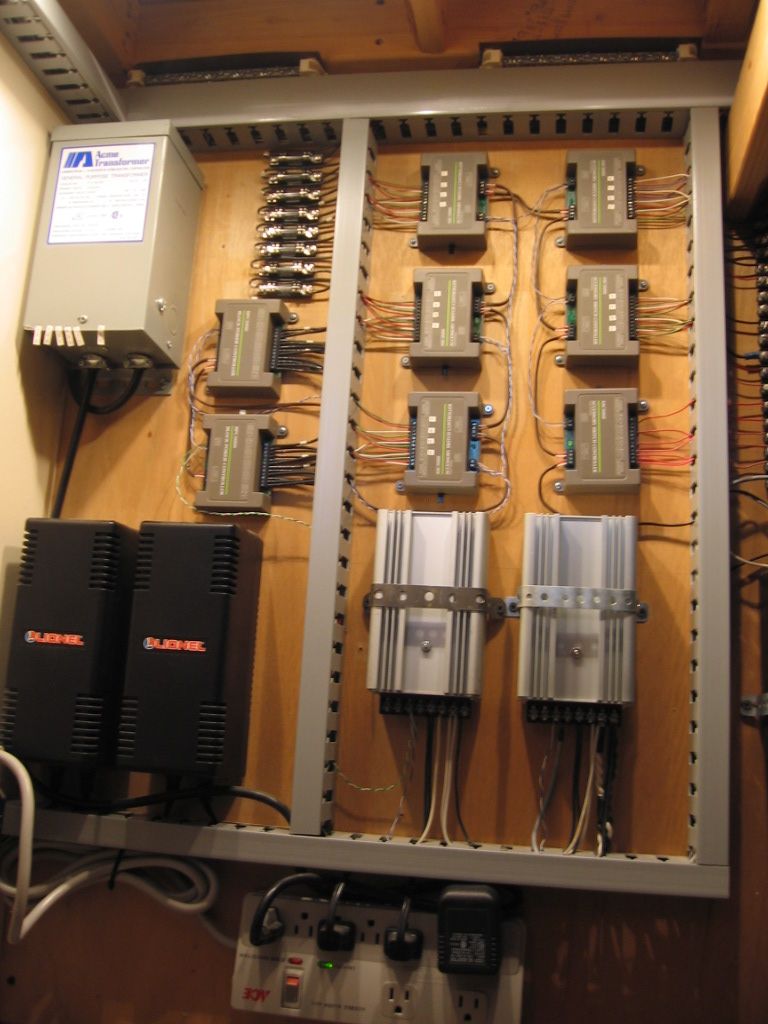

Parallel PH135's are lower left. (8) 7.5amp track fuses that normally blow are upper left. The PH135's parallel to the TPC on the right, and then double off the input terminals back to the one on the left. The (2) TPC (Track Power Controller) outputs are wired to the (2) BPC's (Block Power Controllers), above the PH135's. Each is capable of (2) inputs and (4) outputs. The (8) Track blocks that I have can be arranged via either of the (2) TPC's. I recently arranged the circuits so that the Roundhouse/TT and power district 8 that accounts for (7) sitting engines can be turned of via the one TPC.