My diesel engines run fine over them, but when I run my challenger over it, the sound cuts in and out. Everything is new and is lionel legacy , if that matters

Thanks

|

|

Replies sorted oldest to newest

Several members have suggested to put a power drop at each end of the switch, so as not to rely on the jumpers. It works for me.

This may help you: Wiring an Atlas 6924 N-D Board Yes, even without the non-derail board. This one Atlas turnouts explains you problem(first reply) and has the Atlas pdf for wiring the closure rails.

I hope that helps. The second one seems more appropriate.

The atlas switches are a problem, I have the same problem with my challenger. some have tried rewiring, other just end put a batteries in problem engines.

First try to visually see where the problem is. Run the engine slowly over the switch. When you reach the 1st trouble spot (lights flicker- sound drops out) stop the engine and turn the power off. Gently roll the engine to one side and see where the pickup rollers are in relation to the center power rails. Do any of the rollers look like they are not positioned to make contact with the center power rail. Considering the diesels all seem to run across the switch without a problem it would seem the is a distance issue with one or both rollers not making contact. If there are two independent rollers one could possibly not be wired leaving only one roller for power pickup. Does the condition happen running on both the straight route and the diverging route?

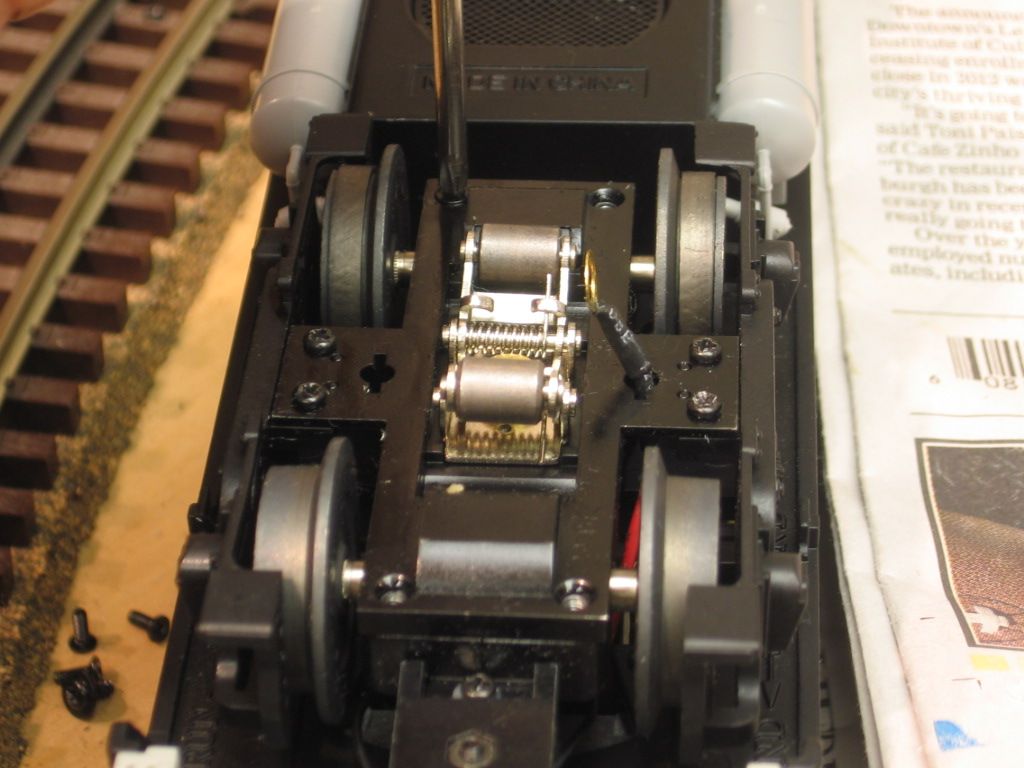

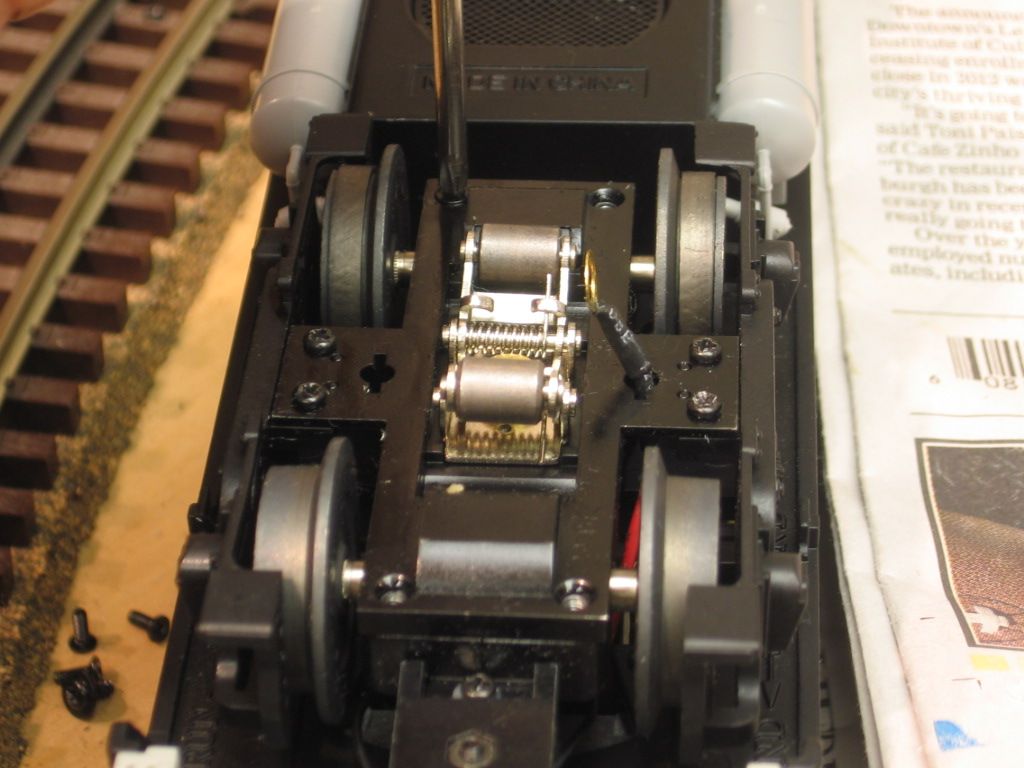

Since the sound cutting out on a Legacy steamer would be the tender pickups, that's the place to look. ![]()

Look at the switch dead spot. These O54 switches have a spot that is about 1 3/4".

These two switches have (2) dead spots about 14 1/2 " apart.

This Weaver E-8 has pick-up rollers 14" apart. It will loose power on the two switch combination pictured.

The other scenario is when the pick-up rollers are close together. Both rollers, very close together, can hit a dead spot at the same time, causing lose of power.

Larger sweeping switches may have larger dead spots than 1 3/4". There has been an effort, at least by Atlas, to provide (4) pick-up rollers on newer issue engines.

Two sets of these per unit/locomotive.

Larger sweeping switches may have larger dead spots than 1 3/4". There has been an effort, at least by Atlas, to provide (4) pick-up rollers on newer issue engines.

Two sets of these per unit/locomotive.

Doubtless because they know about the shortcoming of their switches. ![]()

This has nothing to do with the design of the AtlasO switch.

It has to do with the spacing of the pickup rollers.

This has nothing to do with the design of the AtlasO switch.

It has to do with the spacing of the pickup rollers.

That is correct. All 3-rail switches have the "power gap", and it's a matter of mitigating the gap based on the spacing of locomotive power pick-ups for locomotives in your roster.

One approach involves reducing the length of the power gap by powering the closure rail, depending upon the position of the turnout points. This is pretty much a requirement for the higher numbered scale turnouts (Atlas-O #5 and #7.5; Ross #6, #8 and #10), but can be done if needed for smaller turnouts as well. It involves some extra wiring with relays and such, but it effectively eliminates the issue you're encountering.

David

P.S. The RCS website has some PDF diagrams that illustrate how closure rail wiring is accomplished. Hope that helps.

This may help you: Wiring an Atlas 6924 N-D Board

Thanks for that link. I try to carefully follow all the Atlas-O switch threads. Don't know how I missed it, but have it marked now! Was in on the other one, so I had that. Lot of good info in those other threads and here too.

David, where do you find the PDF diagrams on the RCS site? I'm interested in how they did this, we have a couple of the curved Atlas switches that I'd consider doing this mod to.

Link to a larger picture on the Ross site. Most of these diagrams can be found in the technical section.

Thanks Mike, I figured out it was their standard "documentation" that has the info. I always wondered about this with the Atlas switches, I think I'll try one and see if it cures our issues.

Now that I've seen what they do, I'll probably "roll my own" to do the job. We have a couple of problem switches that are in difficult to reach places that I'd like to fix.

I found that 3 amp fuses inserted in the track power to short dead rail section was a plus. This is not rocket science, close rails and moving wheel through these switch can easily cause shorts. Every one of my Atlas switches has the 3 amp fuse. I routinely check/replace the fuses. Without the fuses I have damaged 6924 relay boards, usually dead shorts burn the traces. On the Fort Pitt Modular layout, I have had the DZ 1008 relays burnout and dead short the track system, requiring relay replacement. The DZ 1008 relay also needs a 3 amp fuse on the track power circuit. IMO.

The Atlas 6924 wiring diagrams show the 3 amp fuse.

Mike CT I would like to thank you for your input on this. You have put so much time into this and you seem to be willing to help all of us with our layouts and the wire we need to pull. I have looked at your photos and it will help me under stand how to wire every thing up as I get closer to the time to wire everything up. Thanks for your input. Scot

John,

Looks like you have what you needed from Mike's post. Those Atlas-O curved switches are long enough that they can definitely benefit from closure rail power routing -- especially to take care of shorter locomotives (or locomotives with closely spaced pick-up rollers).

David

My Legacy E6 Atlantic stops every time on two of them, it's getting old. I'm going to run a small tether between the locomotive and the tender using the Minatronics 2-pin tether just to tap power from the tender when the locomotive rollers are not powered. However, there are other similar locomotives, I hate to have to modify them all!

Mike CT I would like to thank you for your input on this. You have put so much time into this and you seem to be willing to help all of us with our layouts and the wire we need to pull. I have looked at your photos and it will help me under stand how to wire every thing up as I get closer to the time to wire everything up. Thanks for your input. Scot

I will second that to Mike CT also. Got a lot out of several threads about Atlas switches that he contributed to (some were my own). Of course I have gotten a lot of help from many others as well, too many to list, but don't want to exclude anyone. Definitely a great learning place here on the OGR forums. You learn something from someone here every day you read the forums, at least I do.

Access to this requires an OGR Forum Supporting Membership