Anybody on the forum ever hear of this company?

they state that their computer control system is fully compatible with Lionel's T.M.C.C. system.

|

|

Anybody on the forum ever hear of this company?

they state that their computer control system is fully compatible with Lionel's T.M.C.C. system.

Replies sorted oldest to newest

Note they don't mention Legacy... ![]()

Hi MRCRRTECH,

I don't have any personal experience using the CTI hardware, but I know a hand full of people who do. I looked at using CTI on the NorthWest Trunk Lines but decided against using it mainly because of the layout control interface. The CTI hardware is apparently quite reliable and is a good choice for occupancy detection. However, CTI's user interface requires you to learn their programming language and write the control logic for your layout.

There are other choices in layout control software that also support TMCC. One of the most popular is a free open source project called JMRI. JMRI is most often used by DCC operators as a programming aid. The layout control features receive a lot less attention from users and developers, but they are in there. There is another free open source project that I is a good deal more advanced for running layouts called RocRail. The best software control package for layout control, IMO, is RR&Co. Train Controller. Train Controller starts at $130, but is far more refined than JMRI or RocRail.

All three of the software packages I mentioned are fully compatible with TMCC. As John mentioned, they do not support Legacy features such as quillable whistles, but anything you can do with a Cab-1 is supported. Any of these systems needs detection hardware that feeds occupancy and switch position info to the software. You have many choices for detection hardware including CTI, NCE, Digitrax, and Lenz. On the NorthWest Trunk Lines we choose to use NCE because it costs the least per detector on a large layout.

Hope that helps.

Dave

Dave:

Are you using the NCE BD20 current-sensing detectors? I was thinking about using them for block detection on the AGHR layout.

Hi Matt,

No we're not. Since the NWTL is 3-rail scale we are able to use insulated sections wired directly to the NCE AIU (14 detection circuits per AIU) for detection. We're not using any current detectors.

interesting thread

did not know all of this computer control was out here for our railroads

interesting thread

did not know all of this computer control was out here for our railroads

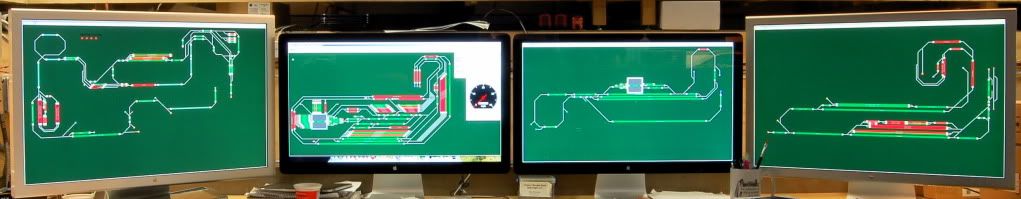

Ho yes. Computer control of model railroads is very much a reality. Here's a look at the main dispatcher's desk on the NWTL.

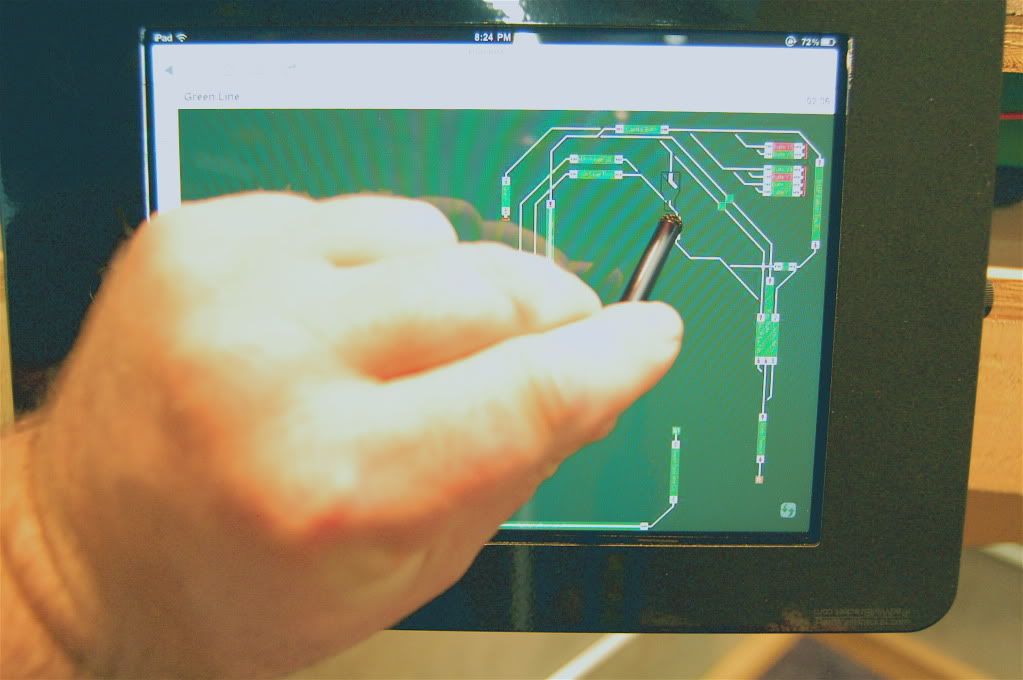

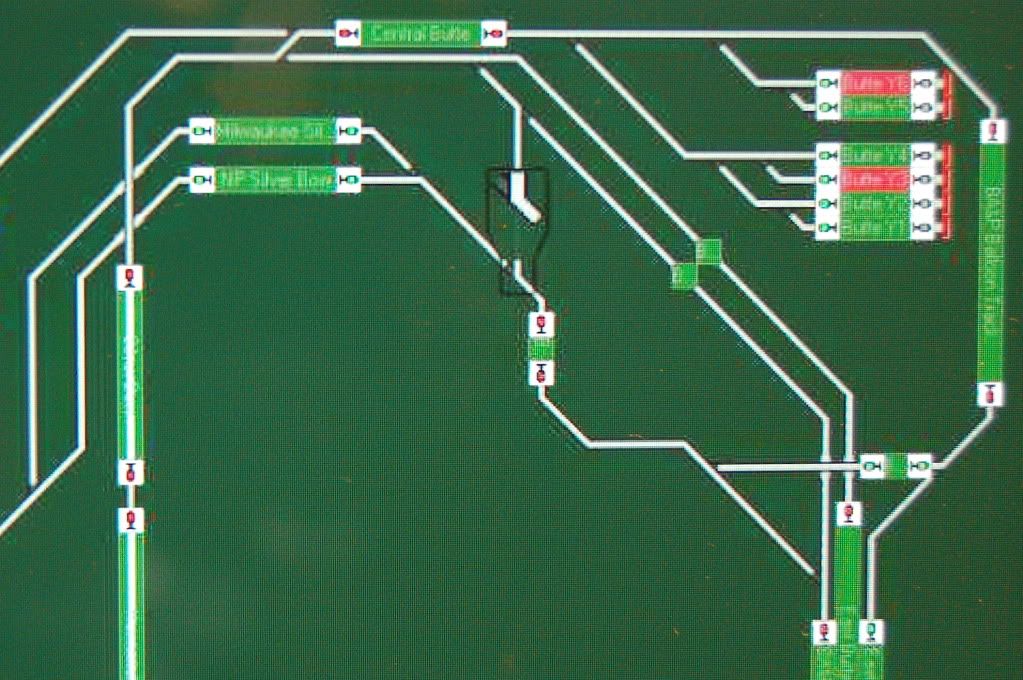

As I mentioned earlier, we're using RR&Co. Train Controller. One of the cool features built into TC is a web server that allows any mobile device with wi-fi and a web browser, such as an iPhone, iPad Touch, iPad, Android phone, Kindle Fire, Blackberry, or Windows phone, to be used as either a locomotive throttle or a control panel. On the NWTL we're using iPads as our local control panels.

The RR&Co. website features a web forum for TC users. There are over 11,000 registered users on their forum (more than OGR). The forum is split between English and German language sections. More than 2/3 of the traffic is in German.

Thank you for the replies

I have the CTI system and it does work quite well. True, there is a learning curve in mastering the control language, but there are great resources on line through individuals who will walk you through it. I had a large museum display set up this year using the CTI system. I opted not to use it to access TMCC and instead went with conventional running. This was because I was not confident that all would go well while I was not there. I do not think the problem was CTI's fault, probably my track work. Not all TMCC features, however, were accessible through CTI, such as the squealing brake sound.

Dave Hickel -- are you running AC or DC, 2 or 3 rails?

I looked at the NCE which all appears to be DC.

CTI states their product can be used with AC. However their throttle controler appears to be just DC and can only handle 50W. Most of us with at least a moderate sized layout have at least 80W. My Type V transformer kicks out 150W.

Anyone know how these would be used with AC? And without TMCC?

Dave Hikel -- are you running AC or DC, 2 or 3 rails?

I looked at the NCE which all appears to be DC.

CTI states their product can be used with AC. However their throttle controler appears to be just DC and can only handle 50W. Most of us with at least a moderate sized layout have at least 80W. My Type V transformer kicks out 150W.

Anyone know how these would be used with AC? And without TMCC?

Hi Jark,

We run the NWTL with TMCC and DCS on AC current. The NCE system is used strictly for occupancy and switch position detection.

As I said above, I don't have any hands on experience with the CTI hardware. Hopefully steammike can share how he configured the conventional control on the display he built. I would suspect that you could control TMCC throttles such as the PowerMaster and TPC's. I know on other projects we have integrated the TPC's with DCS by programming them with an engine address.

Thanks Dave.

I'd like to find throtle hardware that can control AC power in conventional mode. The bulk of my engines are either Postwar or MPC era.

I was able to connect the CTI "Train Brain" control board directly to my ZW transformer(275 watts). For the museum layout I wanted all trains to start with the push of a button. I used a simple Lionel round red spring loaded push button. When the button was pushed it opened a relay to the transformer which was left on at a specific throttle setting. Two trains in conventional and set in forward immediately came to life and travelled on two separate loops until the relay timed out after 90 seconds. I had to write a simple code for this sequence so that the push button defined as sensor #1 when activated or "true" opened up relay #1 allowing power to the track. Then after 90 seconds the relay was ordered closed. Now, I did have the throttle fixed to a set value, but I know the CTI program has a cab control feature so that along with blocks you can vary the value of the power to which ever block you designate in the program.

Access to this requires an OGR Forum Supporting Membership