I am OK with using a dremel to cut brass, but what tools and techniques would you use for "accurately" measuring and cutting brass shapes....Angles or Box tubes?

Replies sorted oldest to newest

For cutting any metal or plastic, I use their Dremel cutting bits, http://www.dremel.com/en-us/Ac...tDetail.aspx?pid=426

I always cut it a little long and then grind it to the perfect length. For angles and other odd cuts, I would use the same idea, cut it at a little larger angle, and grind it down to where it needs to be. For pipe, I have it spin at about 10,000 to 20,000 RPM and I don't force the wheel into the piece, I slowly cut the pipe, so that is leaves a little bur. Nothing a file cant fix. If you are working in tiny rod, then I would set the Dremel between my knees, and cut the rod with it in my hands. I found that to work the best. Hope that helps.

I use tin snipes and a jewellers piercing saw,and files to finish to size. Stephen (cTr... Choose the Right)

Miter box with a fine tooth blade.

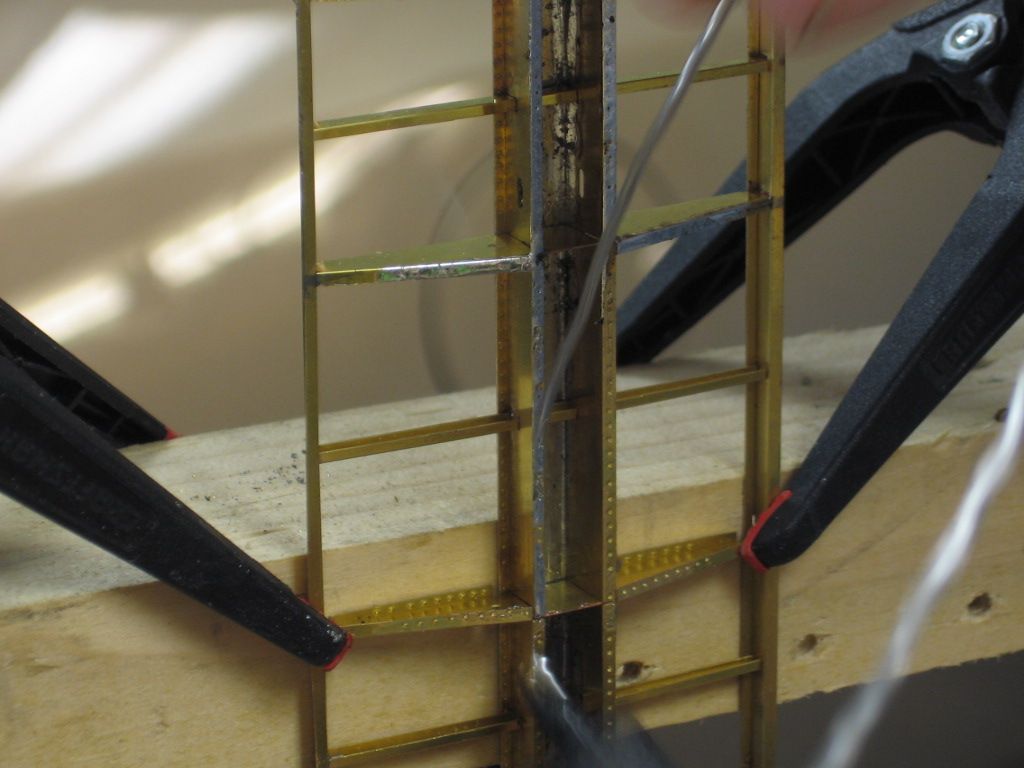

Use mini or micro Quick-Grip clamps to secure the work and box.

I have a very nice bench/disk sander that does a decent job of finishing those fine cuts to fit. Sorry about the lousy picture of the bench grinder.

The miter corner of this gutter was finished on the bench grinder. 1/8" brass C-channel. The downspout is 1/16" brass rod.

Noted: Safety meeting of the day. The bench grinder table allows for a better hold on the small parts. Small particles of brass can be dangerous. Use safety glasses. Mike CT![]()

A bench vice is an excellent additional pair of hands.

These small hand clamps can be purchase at Sear in a set for less than $10. Click on the underlined phrase to link. The 1.5" X 1.5" piece of wood is being held in the vice pictured.

Generally cutting with a Dremel in various small vises as needed to secure the bit being cut. Generally cutting a wee bit long and filing to final fit. Those with lathes and mills probably have other thoughts.

Generally cutting with a Dremel in various small vises as needed to secure the bit being cut. Generally cutting a wee bit long and filing to final fit. Those with lathes and mills probably have other thoughts.

This advice from a long time scratch builder is spot on. Always file or sand to final dimension. Makes for nice neat workmanship and eliminates the need to cut material perfectly with tools that often make it difficult to do so with.

Bob

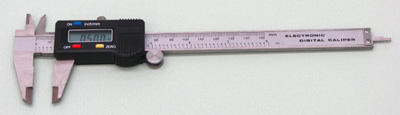

A basic tool for accurate measurement is a 6" caliper. Electronic versions have come way down in price and can easily switch from metric to english dimensions.

Dial versions are also accurate but you would need one specific for english or metric. The best are made by Starrett and Mitutoyo but this one would likely do the job.

Pete

Hey Madison. You look very young and I'm delighted to see you building and modeling in O. I think the point Matt was trying to make is holding a running Dremel between your legs can be a great way to get a serious injury and/or loose some extremities you don't want to lose. If it were to slip and you go to grab it.....whoa that is bad.......and you have an artery inside your thigh that can bleed a man quickly if cut. Why chance it?

Get or make a bench top holder or even use a vise to hold the Dremel, but don't put it between your knees or you could receive an injury to last the rest of your life.

Butch

When I worked in a machine shop (as a draftsman) back in the early 70s, the machinists used "bluing" spray, where they coated a piece of metal with bluing then scribed lines on it where the cuts needed to be. Does anyone use the stuff and where do you get it?

For thin brass (usually under .060") I have a pair of scissors I use to cut the piece out. I also use sheet metal sheers when needed, but on other than flat plates I use a Dremel.

I need to get some of the bluing so I can cut out a new smokebox front for my Seaboard Q3 Mike I'm getting ready to make. From what I can tell, the smokebox front was flat, with a formed manhole cover at the bottom and brackets for the air pumps and headlight. Not only will the bluing help in cutting the piece round, but I'll also be able to space out the location for the bolt pattern around the outer edge.

Bob, I used to use blueing, though mine was brushed on. Now I just use permanent magic marker to do the same thing. Easier to find and just as effective. They are both alcohol soluble and easy to remove.

Pete

Thanks Pete ![]() you just saved me a trip.

you just saved me a trip.

Hey Madison. You look very young and I'm delighted to see you building and modeling in O. I think the point Matt was trying to make is holding a running Dremel between your legs can be a great way to get a serious injury and/or loose some extremities you don't want to lose. If it were to slip and you go to grab it.....whoa that is bad.......and you have an artery inside your thigh that can bleed a man quickly if cut. Why chance it?

That's just what we need to read about on the forums - some one bleeding out from their femoral injury while model RR'ing.........

Get or make a bench top holder or even use a vise to hold the Dremel, but don't put it between your knees or you could receive an injury to last the rest of your life.

Better yet, get a bench top vise to hold the brass that calmps to the bench and hold the Dremel with your hands. The Dremel is designed to used that way and not the other way around. You'd be impressed at how far and how fast a bit of brass can be torn out of your hand to land in either the opposite end of the room or in a body part.

Now I just use permanent magic marker to do the same thing.

I use indelible markers from Sarstedt or the few remaining ink markers I have leftover that used to get used on patients.....

Pete, I went to my favorite mini-lathe site to see if they carried it:

http://littlemachineshop.com/p...mp;B1=Product+Search

so I'm good to go if I need to get some.

I make large tenders from .020 sheet. I find a huge pair of tin snips indispensable.

Whoever suggested layout bluing dye for accurate marking of material to be cut has the right idea. It makes the cutting line easy to see. I have been using a brand called DyChem for years. McMaster Carr carries it and I am sure the Starrett brand shown will also give excellent results. I just paint it on the brass with an old brush. It drys in a few minutes. Scribers, dividers, small machinist squares and a good thin steel rule are layout tools I use every day. You can do some things without these tools but having the right tools really makes the job easy and accurate.

Joe Foehrkolb

.........having the right tools really makes the job easy and accurate.

Joe Foehrkolb

I think that's suitable for framing!

.........having the right tools really makes the job easy and accurate. ..........and safe.

Joe Foehrkolb

I think that's suitable for framing!