I have a 6" cut-off saw from Harbor Freight #61204. I have been using it to cut Lionel tubular track, Ross and Gargraves track. My question is has anyone used this type of saw to cut other brands of track. Thanks Charlie

Replies sorted oldest to newest

Hi Charliez

Check ou this link from the OGR Forum....

https://ogrforum.com/topic/track-cutting

This link may help you out.

Good Luck & Cheers from Michigan

I use the large Dremel cutting wheel you can get at EhobbyTools.

Scott Smith

I use the large Dremel cutting wheel you can get at EhobbyTools.

Scott Smith

I do too, the dremel cutting wheel is the way to go!!! I have a 6 inch cut off wheel that I used for cutting glen's shelves, but it would destroy the track.

I use a Dremel, but that Harbor Freight saw looks like if has a blade that would cut track quite well. Does it work well cutting track, Charlie?

I use a Dremel, but that Harbor Freight saw looks like if has a blade that would cut track quite well. Does it work well cutting track, Charlie?

The cut off saw from Harbor Freight, will give you a squared off cut, every time and keep your fingers. The Dremel Tool can slide off the the track and take your fingers for a ride. Any type of cut off saw is better then a Dremel Tool with a cut of disk.

Good Luck & Cheers from Michigan

So, what's the consensus, Dremel or cut-off? From what I can see, it looks like a pretty even split. I need to cut some track, probably not a lot. The Dremel looks like it'll cost roughly $90 and the cut-off saw about $50.

I like the dremel type, because I can lay the track and cut it in place making sure I get the right fit. Angles etc.... With the cut off you have to take it off the board and hope you cut it right.

I use a Dremel, but that Harbor Freight saw looks like if has a blade that would cut track quite well. Does it work well cutting track, Charlie?

The cut off saw from Harbor Freight, will give you a squared off cut, every time and keep your fingers. The Dremel Tool can slide off the the track and take your fingers for a ride. Any type of cut off saw is better then a Dremel Tool with a cut of disk.

Good Luck & Cheers from Michigan

If you use a regular dremel cut off blade I agree. But if you get the larger cut off wheel from gargraves, you cat cut all three rails at the same time.

So, what's the consensus, Dremel or cut-off? From what I can see, it looks like a pretty even split. I need to cut some track, probably not a lot. The Dremel looks like it'll cost roughly $90 and the cut-off saw about $50.

Hi Bob • It is a hard call, I sill like the cutoff saw, it keeps all fingers ready to go, cut square, and all fingers ready to play the piano.

Cheers from Michigan

if you are cutting track on angles this works best MicroMark Mini chop saw with an abrasive blade

"So, what's the consensus, Dremel or cut-off? From what I can see, it looks like a pretty even split. I need to cut some track, probably not a lot. The Dremel looks like it'll cost roughly $90 and the cut-off saw about $50."

If you need to cut just a few pieces a fine toothed hacksaw blade works great. I use a dremel with thin cutoff disc for some track work but also use a jeweler's saw in many spots( a jeweler's saw is just a very fine version of a hacksaw). Those larger cut offs saws tend to burn the metal due to their wider abrasive wheels.....DaveB

From my perspective a Dremel is one of the more useful hobby tools you can have. $90 if you want to spend that much. I've been using a single speed Model 200 (under $50) since 1984 with a variable controller. Dremel rebuilt it a couple of years ago for next to nothing. I've used it for a LOT more than just cutting track.

Unless you have other uses for a cut-off saw, it becomes a "single tasker" to which my father would have said, "a fool and his money are soon parted". Call this a rant, but i think some of the posters here get carried away with buying tools to build what are not even the greatest looking model railroads. But then to each his own.![]()

jackson

So, what's the consensus, Dremel or cut-off? From what I can see, it looks like a pretty even split. I need to cut some track, probably not a lot.

I own all three types. When I was building the layout with many cuts, the cut-off saw. With the extra-fine tooth metal blade.

When cutting a few pieces, the Dremel for sure. When cutting one piece I would use my jewelers saw. It would take more time to dig out the others and put them away.

If you do a search, there was a member who posted photos of a fig he made for cutting track. It was very simple, and holds the track firm while cutting. I used my compound miter saw, but I used a wood cutting blade, so the cuts were a little rough. An abrasive wheel will do a much nicer job, especially with a jig to secure the track.

Don

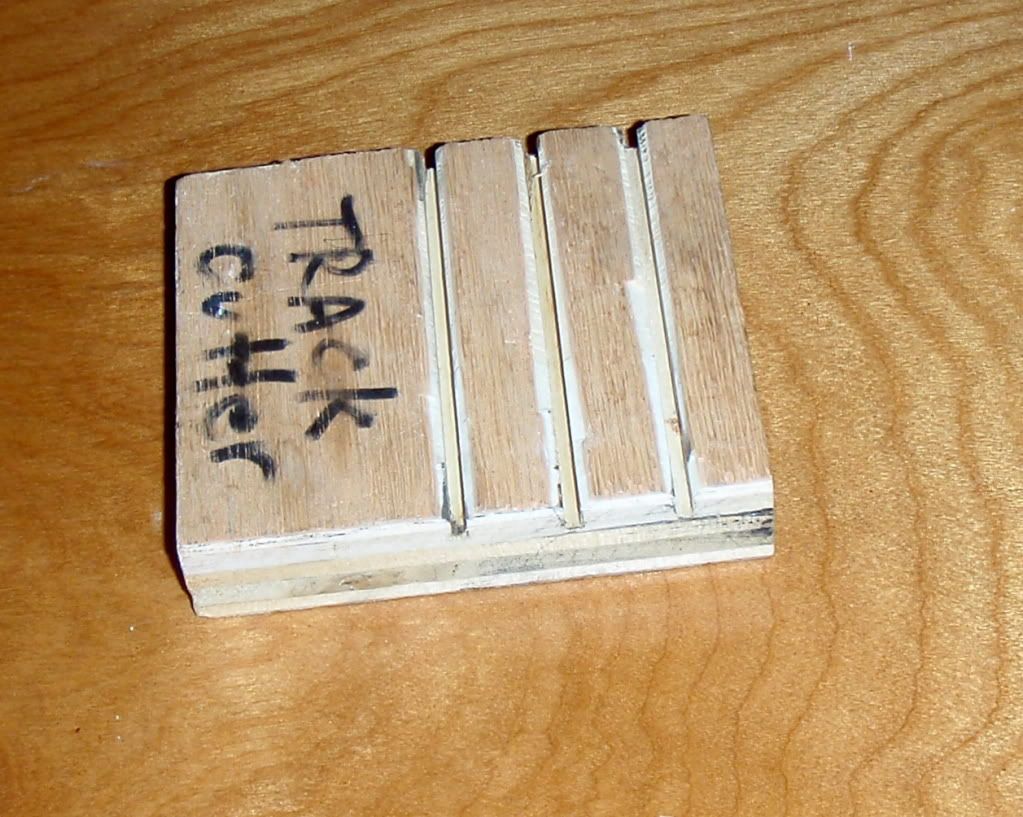

you will need one of these to keep everything in place while using that saw. I usually clamp this to the track and use a fine tooth hacksaw with the jig as a guide for plumb and square

I have a 6" cut-off saw from Harbor Freight #61204. I have been using it to cut Lionel tubular track, Ross and Gargraves track.

In addition to Ross and Gargraves, I've used it to cut Atlas too. BTW, while I was at it, the Closet Maid super-slider rod for my wife's closet.

I use my Dremel with a wire brush to deburr the ends after I cut it.

My Layout has 600ft of tubular track and I used the Dremel for all of the fit ups and then I can use the tool for many other hobby related tasks.

Mikey

As a Dremel user (with and w/o the Flex-shaft) on GG flex track, I always wonder what folks with chop saws or the like use to cut the staggered track ends that inevitably occur when curves are made using flex track, because it's so easy to do with the Dremel or similar tool, and I can't figure out how those cuts can be made with a saw.

Dremel and a hacksaw, 32 teeth per inch. I also true the ends with a disk sander.

The 575 Right angle attachment seems to allow better access to the cut. IMO

Pictured is a 426 reinforced cut off wheel. Exercise caution with the tool, wear safety glasses.

There is also a 402 mandrel part required for the cut off wheels.

Picture from the Internet.

The fastest technique for one offseason get tubular is to use side angle cutters. Pinch it from top on all three rails. Make it a little oversized. Fold down to break it. Usually a few back and firths is enough. Then clean up with disc sander. Use an awl or track pin to

open up the ends if necessary.

I have been fabricating for years and usually make due with the first took I find. Lol. So many "perfect" tools for the specific task that I can never find them. Lol. Probably why I have about 50 tape measures.

i wonder if the Atlas track saw would work, or is it nickle Silver HO track only.

I know how much some guys LOVE to talk about this subject and post pics of all their cutting tools,but don't you think if your method works for those 3 types of track it will work with others?More worry's looking for a subject.Nick

Strictly Dremel user.

CHarlieE,

Over the years I have tried may different cutting tools to handle my custom track making sizes, most all of them are listed above along with a few that also do not appear. This past year another member on the forum said that he now uses the Rockwell X2 Portable table saw for cutting his FasTrack, I took a chance and purchased one of these incredible high speed portable table saws. I got to tell you it works better than any of the tools I used before. Clean cuts at any length and angle needed to close out my FasTrack layouts, the X2 also cuts tubular smooth as glass. This Rockwell X2 Portable Table saw is super light, and cuts all my track super clean, I do not use anything else now. If you are a Military Veteran, purchase from Lowes for $89.00.

PCRR/Dave

Attachments

I want to thank everyone who replied. The chop saw is not my only track cutting tool. I also use the large cutoff disc from Gargraves in my Dremel, also have an air operated die grinder that uses a 4" disc. I have found that the chop saw gives the best cut that is square. Thanks Charlie

Hi Everybody-- Today I was laying track on my layout and planning how to situate crossovers, switches and the like. I had to resort to cutting a 17" piece of tubular track out of a 40" straight. More tomorrow.. However, sitting here at my computer just before bedtime, I keep smelling a "metallic smell" like Tin. The Dremel cut-off wheel gave off lots of sparks and I could feel tiny pieces of something hitting my arms.

I can almost "taste it", too!

Maybe I got contaminated by the Trains. I'll take a good shower and see if there is a difference. Anyone else experience this ?

KRK

I absolutely hate using a Dremel for cutting track. I never get a straight cut, and even the reinforced wheels wear out or break.

When laying Gargraves track, I simply lop off the rails using a pair of tin snips, leaving about a quarter inch to spare, since the snips crush the rail. Then I use a 1" bench top belt sander to remove the crushed bit.

This method is quick, easy and cheap. I would never have gotten as far as I have, if I had to use a hack saw or a Dremel.

I use a bandsaw with a 24-tooth/inch metal-cutting blade. It works very well on Fastrack, Atlas, and MTH track. The only problems I have had is with the center rail or Superstreets/EZ-Street track: it pays to tilt the track so the blade goes against it at an angle.