I have built a drop bridge (using two brass door hinges) across a 3' opening. At one end I have two pieces of O-31 straight tubular track that line up without steel pins. I am looking for suggestions on how to secure their alignment without pins. Thanks. Rick

Replies sorted oldest to newest

I attached a shelf support peg to a block of wood, then made slots in the block and attached it to the benchwork. This enabled me to move the block slightly to the left or right as needed to keep the rails in alignment. Sometimes as the seasons change, I've had to move it slightly, but since upgrading my dehumidifier last summer, humidity levels in my train room are more consistent and I haven't had to make any adjustments to the pin.

Attachments

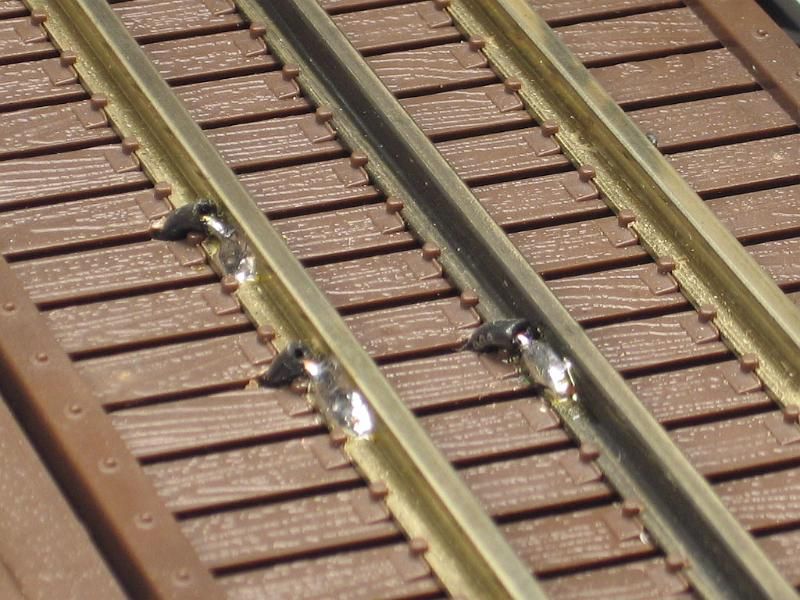

I modified some Atlas rail joiners to line up the outside rail. After I close the bridge, I can slide the rail joiner with my fingers using the modified wing I soldered on.

Attachments

This approach may not be as cool but I am pretty lazy. Put pins in the track on the 'bridge' and cut the top of the rails out on the 'table' track. If you are concerned about the track being level, solder the pins in and build up the top of the pins so they line up with the top of the other track.

Just to be clear. By drop bridge. I’m assuming it drops down towards the floor. The reply’s offer some good suggestions. But looking at the photos. They look like they are for a lift bridge.

Can’t offer a good solution for a drop bridge. Your best bet may be to fix the track well and insure the bridge aligns. A deadbolt latch may work.

Try some earth magnets.

Pictures would help clarify.

Brendan

Unfortunately, that direction of travel goes against gravity. Do you have issues with vertical alignment and horizontal?

Brendan

Lehigh74 How do you open and close that bridge? Do you have to pull those rings on the right? How do you reach that ring on the inside when you are standing at the door?

Ron

The transom latches hold both vertical and horizontal alignment quite nicely. I pull the rings to open from either side (door or staging area). The drop down is 25 ¾” wide with a span of 32 ½”. Mr. Barrett made a slick pulley and lever system on his so he didn’t have to stoop, but that (stooping) hasn’t been a problem for me as it is 4' off the floor.

Drop-in bridge. Atlas Pratt Truss bridge. Opening was built to the bridge dimensions. Yes!!, the door is locked.

Drop-in Bridge, lifts-out, and stores, under the layout, near the door.

@Lehigh74 posted:The transom latches hold both vertical and horizontal alignment quite nicely. I pull the rings to open from either side (door or staging area). The drop down is 25 ¾” wide with a span of 32 ½”. Mr. Barrett made a slick pulley and lever system on his so he didn’t have to stoop, but that (stooping) hasn’t been a problem for me as it is 4' off the floor.

I am thinking of expanding around the wall but need an opening. I had ruled out drop for alignment and lifting reasons but maybe it would work. Could probably add a counterweight or similar. I'll have to check out the article.

Brendan

@Brendan posted:I am thinking of expanding around the wall but need an opening. I had ruled out drop for alignment and lifting reasons but maybe it would work. Could probably add a counterweight or similar. I'll have to check out the article.

Brendan

If you are concerned about weight and want an easy and smooth lift, you could install a car hatch gas shock. I used one on mine. Works great.

Attachments

@Ron That would help. My other concern with the drop down style is the bending down. With the gas shock and rope to pull it up, it could work. When down, it would be like the hatch is closed. The shock could help it go up (hatch open). Thanks

Brendan