The age old question. How do you clean off the black center rail to solder feed wires? I have tried to use a Dremel tool's little wire wheel and can't get it clean enough to hold solder. I have tried to file it, and the only thing that sort of worked was a Dremel grinding stone. But the stone easily cuts into the web of the rail. My track is already in place so I hate to think about pulling it up to use Gargraves spades. I should also note that I have no problem making a nice smooth solder joint on the tin rails. Thanks.

Replies sorted oldest to newest

Grind the black off the sides with a dremel cutoff wheel

I would not use a cutoff wheel as you will have the same problem you have with your grinding wheel. Use a wire brush attachment. I use this on Atlas track and it works very well. I am not sure why this would not work on gargraves...

Part of the problem is that the silver rails have a tin/galvanized plating, which may also be there on the black rail. Aggressive removal of the black may also remove any galvanize which IMO make soldering more difficult. Also The dremel cutting wheels and grinder tips leave material on the surface that can be a problem. On occasion I have been know to use plumbing flux to do a trouble-some solder joint. once the bare metal is tined, attaching the wire is no problem.

Well that is the way i have been doing it for thirty years and never a problem.

The coating on Atlas is different.

Clem k

Part of the problem is that the silver rails have a tin/galvanized plating, which may also be there on the black rail. Aggressive removal of the black may also remove any galvanize which IMO make soldering more difficult. Also The dremel cutting wheels and grinder tips leave material on the surface that can be a problem. On occasion I have been know to use plumbing flux to do a trouble-some solder joint. once the bare metal is tined, attaching the wire is no problem.

Grind the black off the sides with a dremel cutoff wheel

I would not use a cutoff wheel as you will have the same problem you have with your grinding wheel. Use a wire brush attachment. I use this on Atlas track and it works very well. I am not sure why this would not work on gargraves...

Jeff,

I use either one of these Dremel tool bits to remove the blackening from the center rail of GarGraves track.

These bits will not cut the track and thay will make a clean area on the side of the rail that is great for soldering. I use flux from Radio shack.

Hope this helps.

Richard

Attachments

I use none of the above I found those screwdrivers we use that have the swivel tops on them.

they fit right in and scrape the rail shinny bright.

Jeff,

I use either one of these Dremel tool bits to remove the blackening from the center rail of GarGraves track.

These bits will not cut the track and thay will make a clean area on the side of the rail that is great for soldering. I use flux from Radio shack.

Hope this helps.

Richard

Part of the problem is that the silver rails have a tin/galvanized plating, which may also be there on the black rail. Aggressive removal of the black may also remove any galvanize which IMO make soldering more difficult. Also The dremel cutting wheels and grinder tips leave material on the surface that can be a problem. On occasion I have been know to use plumbing flux to do a trouble-some solder joint. once the bare metal is tined, attaching the wire is no problem.

Plumbers flux should be avoided because it is an acid and will eventually cause corrosion and loss of conduction. Use electrical Rosin flux, as that is only acidic when hot.

Part of the problem is that the silver rails have a tin/galvanized plating, which may also be there on the black rail. Aggressive removal of the black may also remove any galvanize which IMO make soldering more difficult. Also The dremel cutting wheels and grinder tips leave material on the surface that can be a problem. On occasion I have been know to use plumbing flux to do a trouble-some solder joint. once the bare metal is tined, attaching the wire is no problem.

Plumbers flux should be avoided because it is an acid and will eventually cause corrosion and loss of conduction. Use electrical Rosin flux, as that is only acidic when hot.

I use the dremel fiberglass cut off wheel, lightly touching it to the area, on slowest speed. Been doing this for years. Don't press. Just a touch will do. And move it about

I use the dremel fiberglass cut off wheel, lightly touching it to the area, on slowest speed. Been doing this for years. Don't press. Just a touch will do. And move it about

I use a nail set, diameter approximately 3/32 inch at the tip, and wrap this conical tip with emery cloth sand paper, grit 100 to 150, and sand this area to bare(silver) metal.

Prior to soldering the solder areas must be surface cleaned no oil, grease or other contamination. I found that this method removed the black finish to silver metal without gouging the rail side(web) or the rail base, sometimes I apply a solder flux to this cleaned area with an inexpensive acid brush prior to soldering.

Amazing what you can do with a little plumbing flux.

Clem,

Grind the black off the sides with a dremel cutoff wheel

I completely agree. It's worked for me every time.

Clem,

Grind the black off the sides with a dremel cutoff wheel

I completely agree. It's worked for me every time.

Me too

A small file or flat blade screwdriver followed by a little Radio Shack rosin soldering flux has always worked well for me. I get a good flow of solder on the track first and then return to connect the lead on a second pass. Less cooking of the insulation.

I had a devil of a time soldering the wire to the middle rail. What I finally did in a couple spots is insert the rail joiner and soldering that. And use a lot of heat.

Dick

Soldering to Gargraves requires a LOT of heat also. If you are having a hard time soldering to a clean middle rail, your soldering gun (Not Iron) may be too small.

You don't need a Dremel to remove the black coating. Any sharp object will do to scrape it off. I have used an Xacto, a chisel and even a screwdriver. Once you see bare metal, apply rosin type flux and heat it up. Get the solder to stick to it before you try to attach the wire (tinning). Then tin your wire. You may not even need to add more solder, just heat both up.

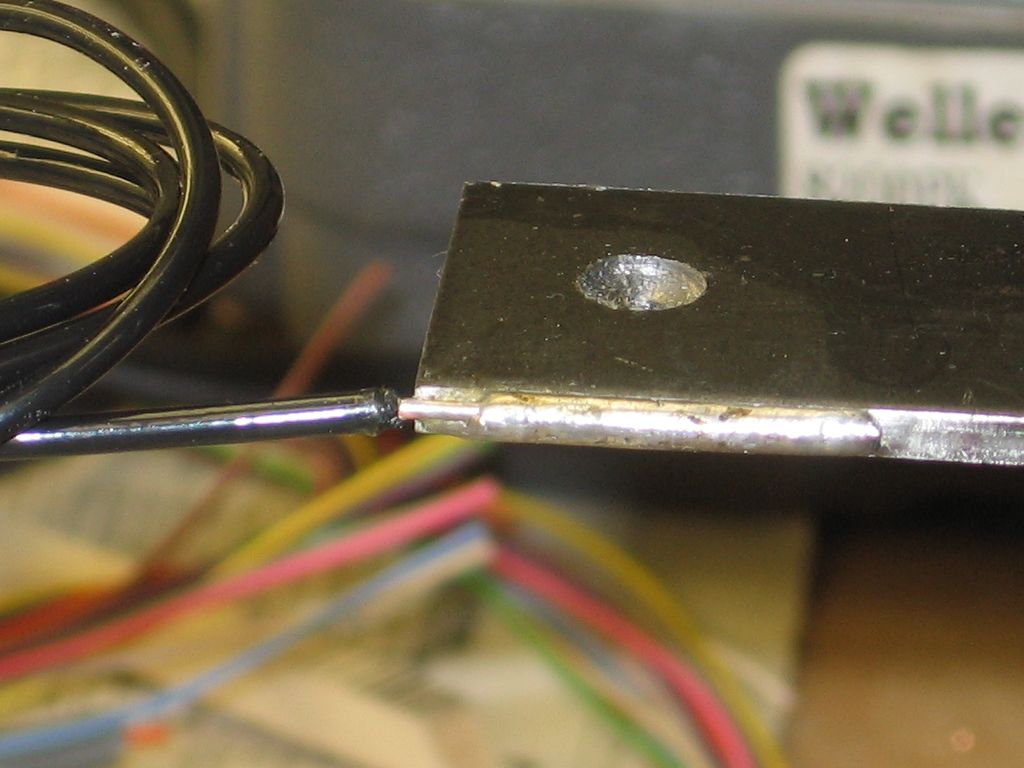

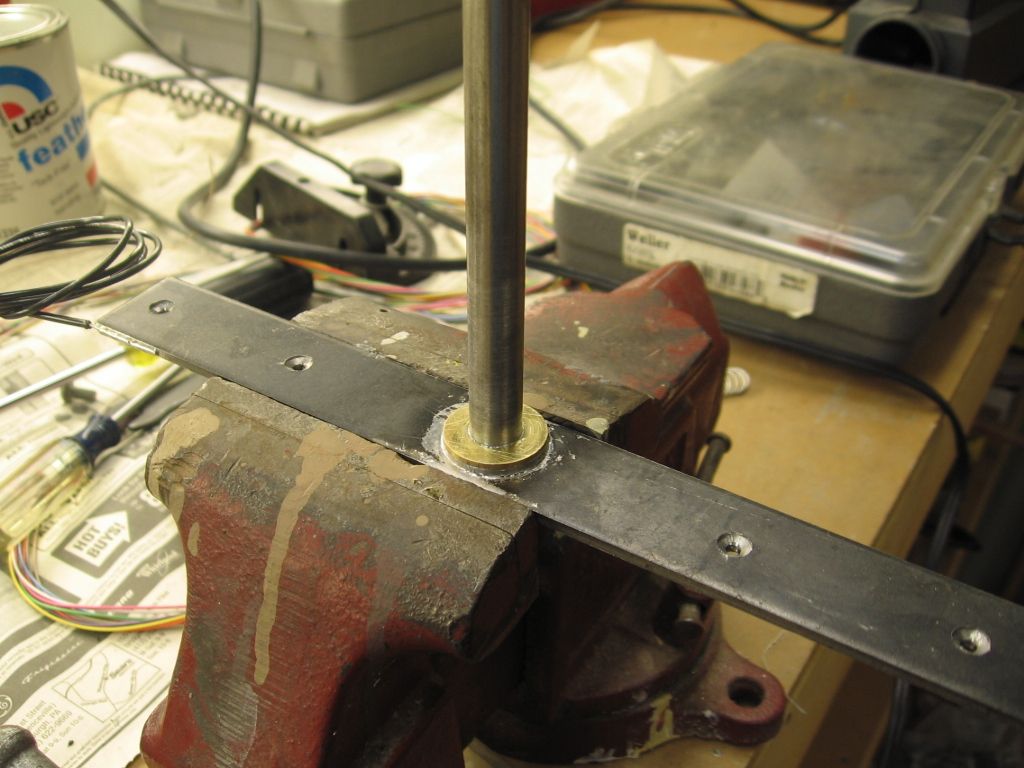

Another possibility is to drill a hole (just large enough for the wire to fit into easily) through the lower flange of the rail. Insert the wire, apply heat and solder.. The solder will stick to the bare metal on the sides of the drilled hole and, of course to the wire. This produces a very neat joint.

Another possibility is to drill a hole (just large enough for the wire to fit into easily) through the lower flange of the rail. Insert the wire, apply heat and solder.. The solder will stick to the bare metal on the sides of the drilled hole and, of course to the wire. This produces a very neat joint.