Below is a photo of the set up : wire to #1N4001 diode to wire. Other than soldering diode to wires, are their any connectors available to do this? Don't have a soldering gun .Not for the cost, I just prefer not to purchase one. I've gotten this far with the layout without the tool.

Replies sorted oldest to newest

You could use crimp connectors, but why?….a soldering iron would make short simple work of that, …..not sure how you made it this far without one, but,…ooook,….your layout is just like Burger King, ….you can have it your way!…😉

Pat

These Wago 221-412 Compact Splicing Connectors would work, but they're not cheaper than an inexpensive soldering iron if you have lots of connections to make.

Here's one with a 1N4001. In my testing they will securely hold a wire as small as 29 gauge.

Attachments

Attachments

@TedW posted:

Ted I've considered this in-line configurations as well, but I don't have any of these yet, mainly because the 221-2401 model claims to only work down to 18 gauge. Have you tried these with smaller wire? If so, what's the smallest they will hold securely?

I'm with harmonyards on this one.

Buy a small soldering iron and learn how to use it. This would be a simple, 30-second job with a soldering iron and about 1 cent worth of solder.

Learn how to solder. You need a good soldering iron or gun. They're not that expensive and once you get one you'll kick yourself for having not bought one sooner.

With apologies for nudging you to the soldering group, here's a basic set that will help you perform numerous tasks in model railroading. LDK-Soldering-Adjustable

@luvtrains posted:Other than soldering diode to wires, are their any connectors available to do this? Don't have a soldering gun .Not for the cost, I just prefer not to purchase one.

I'm with @SteveH on this one.

.

These have teeth inside and are designed to crimp two or three wires in the 26 to 22 gauge range. Ask your local alarm company guy for a handful. Or contact me directly off-forum and I'll send you some.

Also called "dolphins" or "good-n-plenties."

I agree with all the above comments re: value of owning a soldering iron and learning how to solder. But for my own edification, I tried connecting a 1N4004 to #20 stranded wires just using gray wire nuts. Worked perfectly giving a tight connection. (Don't ask me to repeat for smaller diameter gauges. ![]() )

)

Attachments

Wow! You all are so helpful. Thank you.

When I started back in the hobby in late '21, soldering was the first thing I knew I had to master. I thought I was pretty good until I tried to solder a wire into @gunrunnerjohn's LED regulator and destroyed it. I asked GRJ if there was an easier way to connect an LED string to his device and his reply was 'Learn to solder'. I said okay to myself, and worked on it. Right now I'd put myself at a level 7 out of 10. I now have 2 different solder guns, one for accuracy and one to solder things to big stuff that needs a lot of heat.

@texgeekboy posted:I now have 2 different solder guns, one for accuracy and one to solder things to big stuff that needs a lot of heat.

Well, solder "guns" are not what you use on circuit boards! There are many choices, but my choice is the Hakko FX-888D soldering station. This is a top quality soldering station that has precise temperature control, unlimited choices of tips for special projects, and 70 watts of power when you need it. The key, however, is tip temperature control. When you're working with PCB boards, you don't want excessive heat, but you do want a fine tip.

Also, a $20 calibrator will allow you to insure accuracy of the tip by calibrating it to an actual measured temperature.

FG-100 Digital Soldering Iron Tips Thermometer Temperature Tester

Attachments

I say guns, but I have a hakko iron (not the one in the pic) and a big Weller for the big jobs. Holding a soldering gun for detail stuff isn't something I could do.

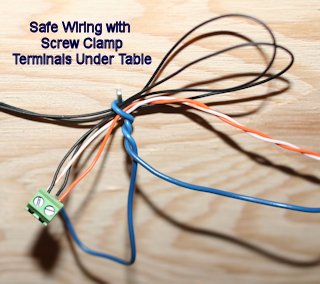

As seen one of my web pages, Toy Train Layout Wiring - Wire Management

These little terminal blocks work good for smaller wires twisted together.

Here's the All Electronics example. Snip off prongs and wrap w tape if needed.

All Electronics site

2-POSITION PCB TERMINAL BLOCK

with screw clamps for tiny wires.

Back when Radio Shack had stores, I bought a set of half-dozen clip-on heat sinks for soldering delicate components. Basically aluminum "clothes-pins," they prevent heat damage when using my regular Weller soldering gun and solder won't stick to them. Since my layout has something like 5,000 (seems that way) solder joints, I can't imagine building a model railroad without learning how to solder, even if you use it only for wiring. Soldering is also vital for other metalworking. For example, I'm in process of revising the MTH SW-1 I bought with a custom made smokestack to match B&O 208/8408. This required soldering a .015" diameter brass wire around the circumference of a suitably sized brass tube (.015" was a compromise. The prototype has 1" half round, which would be .020" half round in O scale--.020" vertical, .010 horizontal). Also love my ancient American Beauty soldering iron with thermostatically controlled stand, purchased used for $20 decades ago. Nothing like it for soldering my 20 gauge drops to my 12 gauge busses and to track. I'm no expert, as I have more than once found my failed solder joints to be the source of operational issues. Still, I'm with those who advise taking the plunge into soldering. Learning new stuff is a big part of what this hobby is about!

@Bruce Brown posted:I agree with all the above comments re: value of owning a soldering iron and learning how to solder. But for my own edification, I tried connecting a 1N4004 to #20 stranded wires just using gray wire nuts. Worked perfectly giving a tight connection. (Don't ask me to repeat for smaller diameter gauges.

)

So, you put that inside a what ? That looks like a short looking for a place to happen. I cannot count the dead Locos I bought for CHEAP on eBay with just such wiring. People who run conventional might get away with this but if you are running DCS or TMCC/ Legacy your looking for trouble and $$$$ for repairs. Any tape inside an expensive train is also looking for trouble when it comes loose or best case just leaves sticky goo all over. As for the OP you can purchase a perfectly adequate soldering iron for under $10 and order some Heat Shrink Tubing while your at it. In the course of your life as a model railroader both these items will pay for themself a hundred fold. As far as soldering guns are concerned DON'T USE THESE ON ELECTRONICS. Soldering guns are induction devices which create an AC voltage potential at the tip of the gun. My Weller guns have a tip potential to ground over 30V. That will fry many solid state devices. j

Thank you for all of the help. SteveH and TedW thanks for the Amazon links. I ordered the LDK solder and the Wago 221-412 connectors. Also forgot I had those connectors but not enough of the ones you recommended. I will start to practice with the solder which I probably will use for repair on wire connections. The layout is near completion (scenery, etc.) But I will always will be working on it. It's good therapy for me... so to speak.