The Trackman 2000 cleaner was relatively simple, used a couple of different pads that could be fabricated if you did not have access to them. Additional cleaning may be required inside of outside rails, IMO

|

|

The Trackman 2000 cleaner was relatively simple, used a couple of different pads that could be fabricated if you did not have access to them. Additional cleaning may be required inside of outside rails, IMO

AlanRail posted:here is why none of these work well enough. THERE IS TOO MUCH SURFACE OVER THE LENGTH OF THE RAILS AND NOT ENOUGH "clean" SURFACE ON THE CLEANING PART(S) OF THE CLEANERS.

As soon as the cleaning parts are saturated with crud they stop cleaning and you are just spreading the crud along the remaining length of the rails. What is needed is a way to vacuum or remove the crud as it builds up on the cleaning parts. Until that is invented, your hand, a clean rag and some cleaning solution and your elbow is the only way to really clean the track rails.

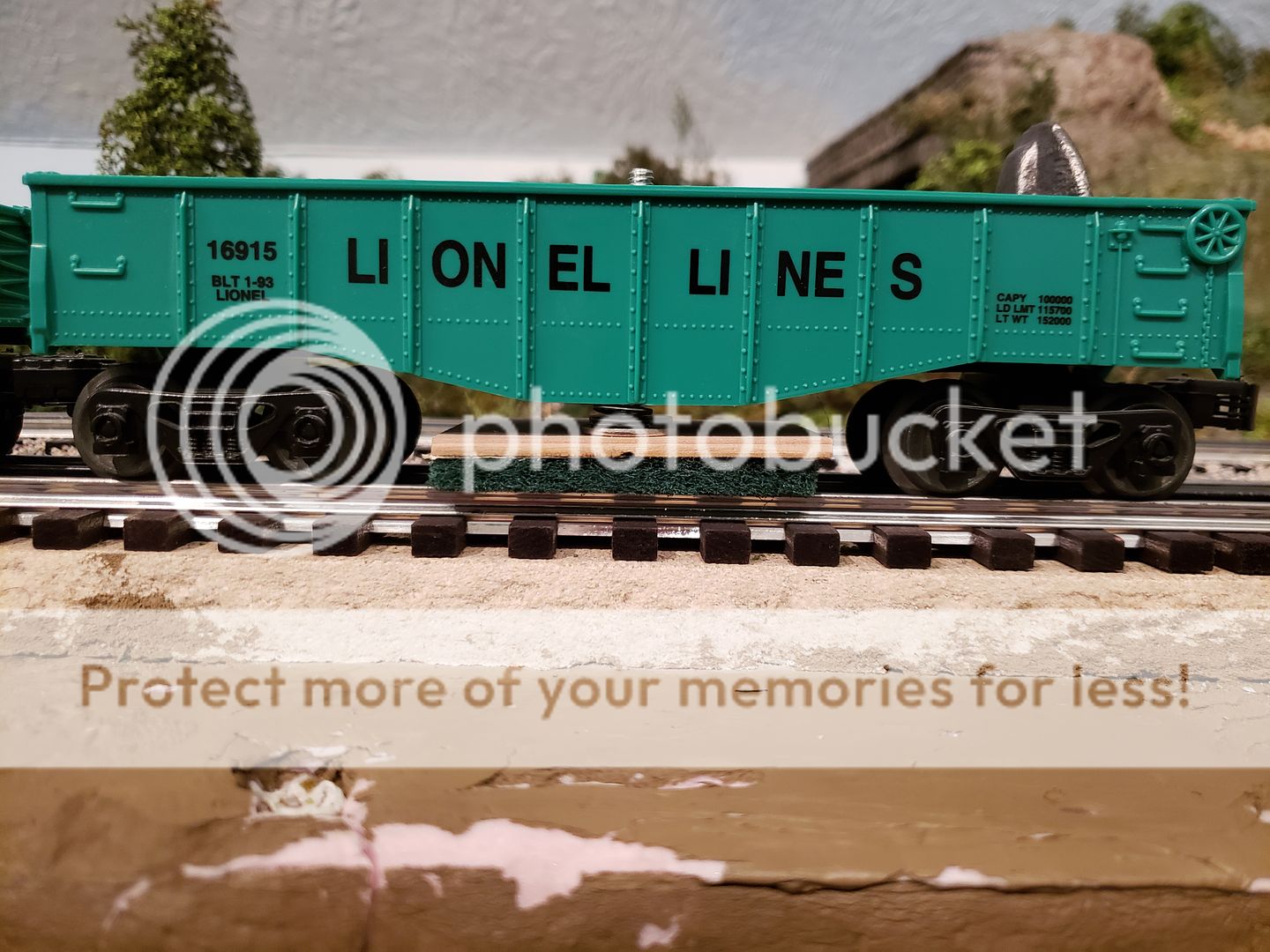

Agreed 110%. Along with a rag and some cleaning solution, here's probably my best track cleaning car. Notice it has no wheels or couplers. ![]()

![]()

Any comments on the R&L track cleaning car?

A comment regarding acetone. It is an excellent cleaner, but can do damage. To illustrate, I left a quart can of it on the deck of my cabin cruiser. (stupid!) When I came back a few days later, the can had tipped & leaked, doing unrepairable damage to the deck. Consdier you may have [plastic parts in switches and in switch motors, so it could be risky for them.

I cam a across a review of the CMX car. It is attached

I had not heard of the CMX cleaning car until mentioned in this thread...it does appear to be as good as it gets with regards to commercially available products. I found this review by Eric's trains:

How about 3 Fingers on a cleaning rag saturated with GOO GONE ? !

LOL

FREDSTRAINS

Fredstrains posted:How about 3 Fingers on a cleaning rag saturated with GOO GONE ? !

Sure, if you can conveniently reach all areas of the track. That's possible on some layouts, of course, but on many it is not really easy to do without damaging scenery, structures, etc.

Allan Miller posted:Fredstrains posted:How about 3 Fingers on a cleaning rag saturated with GOO GONE ? !

Sure, if you can conveniently reach all areas of the track. That's possible on some layouts, of course, but on many it is not really easy to do without damaging scenery, structures, etc.

Just kidding, however I m fortunate to reach all my Track from the edge of the Layout!! On my last Layout (which was much bigger), I had good luck with the “Northeast Trains” Track Cleaner Cars! Using 2 in Tandem! The first one with Pads wet with Goo Gone, and the 2nd one with Dry Pads! Worked very well!

Fredstrsins

I recall an article done by resident OGR tech guru Jim Barrett, where he modified a Lionel track cleaning car to use a Scotchbrite pad in place of the foam one. Can't tell you all the details but maybe Allan A can point you in the right direction

Dennis LaGrua posted:I recall an article done by resident OGR tech guru Jim Barrett, where he modified a Lionel track cleaning car to use a Scotchbrite pad in place of the foam one. Can't tell you all the details but maybe Allan A can point you in the right direction

I made mine by photocopying a foam pad and using that as a template for cutting out the thin Scotchbrite pad - the one without the sponge. Works a bit better than the original.

New Haven Joe, how do you hand clean the NE trains track cleaning pads? I've had some soaking in Dawn detergent & water, and can't seem to dent the grime.

For those who use CRC products, whuch are generally very good, I would point out that if you go to their website and check the Product Data Sheet for the item you plan to use, some are not plastic safe. Brakleen and Lectra-Clean 3000 are not. QD electrical cleaner appears to be.

To directly answer the subject title,,,,,,,,,,yes there IS a "cleaner" that actually works.

1) take a short piece of 1"X2" pine, about 4" long.

2) Wrap a soft cotton rag TIGHTLY around the piece of wood.

3) Moisten the cotton with denatured alcohol.

4) Apply physical effort to CLEAN YOUR TRACK!

For what it's worth, there was no place on our layout that I couldn't easily reach, plus the layout was constructed so that I could actually climb up on it and walk around on the tracks, without damaging any scenery.

RJR posted:For those who use CRC products, whuch are generally very good, I would point out that if you go to their website and check the Product Data Sheet for the item you plan to use, some are not plastic safe. Brakleen and Lectra-Clean 3000 are not. QD electrical cleaner appears to be.

brake cleaner will clean up track like nobody’s business, that stuff can’t be good for you though. i definitely wouldn’t use it around certain plastics, or paints for that matter.

I’ve used CRC Brakleen for years. Make sure you use the one in the red can. It probably would harm plastic. I have Gargraves and have never had an issue. Best thing is. It is non Flammable. The version in the green can is. I use it on a rag. Wrapped around a piece of wooden block. Or in a CMX track cleaning car.

I've been using it for years on my NE Trains car, but it evaporates very fast. QD elecyronic cleaner doesn't seem as effective. There is a QD Contact cleaner and a QD electronic cleaner. I don't know what is the difference

Dave, do you buy it in non-aerosol containers for the cmx? The cmx is very attractive.

Russell posted:I made 2 cleaning cars from old plastic Gondolas, Drill 2 holes in the middle of the car spaced inside the wheels. Drill the same holes in 2 thin wood plates a bit wider than the tracks. Push carriage bolts through the wood then put a good spring on the bolt, then push thru the bottom of the car and add a nut inside the car. Add car tire balance weights in the car, use enough to overcome the springs below and keep the wheels on the track. Glue or otherwise secure a kitchen dishwashing sponge with the scrubby back facing the track to each wood pad. Mount a magnet just above the track to one end of one car to catch metal bits falling on the track. In front of a train or engine, Run them once a week all over the layout. This setup worked great on my old layout and I expect it will also work on the new one in progress.

Here's mine, I modified a pair of gondola's just like Russell described above. I wet the first scotchbrite pad with denatured alcohol, the second one with goo gone and it's followed up with the Lionel track cleaning car thats dry to mop things up. It works great provided I keep up with it by running it around the track a few times every other week or so....

Paul

RJR, I just buy it in the aerosol can. My track doesn’t need cleaning very often. I spray it into a plastic bottle with one of those flip open spouts. Easy then to dribble it on a rag. Or with a funnel. Fill up the cleaning car.

I use 2 centerline cars, both with goo gone. I put round fishing line weights in the tube. It rolls good that way.

Then I walk around the layout and manually scrub with a scotch bright pad, or a rag, while the cars are going around the track.

I’ve found that the best way to keep the track clean is by judiciously oiling engines and cars. A little goes a long way.

RJR posted:There is a QD Contact cleaner and a QD electronic cleaner. I don't know what is the difference

Isn't one flammable? http://api.crcindustries.com/a...rvices/get-pds/03130

And the other non? http://api.crcindustries.com/a...rvices/get-pds/02180

I e-mailed CRC and got the following reply:

Hello,

02130 and 03130 are the same item just different sku, marketed to different types of industry- 05103 while not exactly similar chemistry wise is a comparable alternative sold to our automotive industry.

My e-mail was as follows:

Can you please tell me what is the difference among these 3 products:

#05103 QD Electronic Cleaner

#02130 QD Contact Cleaner

#03130 QD Contact Cleaner

Thank you

-----------

Here's link to the CRC catalog, where you can see what affects plastic, etc:

https://www.crcindustries.com/.../industrial-catalog/

@sidehack posted:yup 91% alcohol does the job

Does the 91% alcohol work on fastrack

@DAVID PEARSALL 010218 posted:Does the 91% alcohol work on fastrack

Works fine, but the "dirt" comes back pretty quickly A non-polar cleaner will last longer.

A friend who had to frequently clean his track for contact issues was using alcohol. A reasonable guess like many here. BUT he switched to dampening a sock with wd40 and hardly had to clean his track at all for months.

Just say’in…

Mineral spirits works well for me.

Has anyone tried this: https://www.trainworld.com/bac...-bachmann-99992.html I tried to buy it a month ago but it went out of stock before I could complete the transaction. For my HO track, I've been using a Walthers CSX track cleaning boxcar. It's much to heavy for one engine to pull, so I do it by hand. It's like soap stone. I was worried it would scratch the track but nothing has been seen at this point. I'm really amazed at what it picks up from the top surface. However, it only does the top surface. For the sides, I use a paper towel with frequent rotation.

I also noticed there is a block you can get that will clean the wheels themselves. But that also is a manual process. Unless I'm completely mistaken, the high end HO cars that have metal wheels have a very light surface covering of machine oil and this eventually transfers to the track.

Anthony

For wheels and rollers, I use a Dremel Wire Wheel, does a great job.

I have no dog in this fight, and don't intend to risk Fido by entering it, but I note that graphite is an excellent lubricant. A good coating on the outside rails should improve wheel spin drasticly, especially when trying to move a long train. Many of the non-polar solvents do leave a residue.

For wheels and rollers, I've gone to using these small abrasive balls, which come in a variety of grits and fit a Dremel and seem to be a little less abrasive than a wire wheel and little pieces of wire don't get all over the place.

I do a lot of switch restoration and cleaning. I use Kingspor Sandflex hand blocks, fine grade. Does a great job. I follow up with my Dremel 428 polishing brush.

Based on experience, I strongly recommend that, if you use an abrasive, you run a magnet over the tracks. Especially if you have magne-traction.

I have heard using NO-OX-ID A-Special on the track after cleaning from the ho and n scale people on youtube but I have not used it and not sure what it would do for traction as the goal with it is to have a micro film on the rails.

Keith1366 and others

Keith, you beat to it about NO OX. NO OX has been used on model railroad tracks since the 1940s. Linn Westcott, the original editor of Model Railroader, used to treat his train track with No-Ox ID A Special and stated he knew other people who did as well, and they never had to clean their track aside from occasionally vacuuming up debris.

Read more: https://dfarq.homeip.net/how-t...track/#ixzz7KK83r7vW

NO OX is an electrical conductive grease and reduces sparking. It is used to reduce sparking in many switching and wire connections in industrial applications. Dust and oil and grease from engines cause dirty track and train wheels and sparking oxidizes it.

You can clean track successfully with a dozen or so cleaners, cleaning cars, etc. To me the promise of NO OX is clean the track and engine wheels once, apply NO OX and never clean track again. I have cleaned my track with mineral spirits and applied NO OX to my O27 track in December 2021 and have updated a NO OX topic on OGR here. We will see if track cleaning for me is over!

My trains have never run better and they now can run really slow. I have 027, 31 Marx switches and run mostly post war locos. Better electrical pick up from the center rail and no sparking are great.

https://ogrforum.com/...1#158955947792824251

Charlie

I think there is no perfect solution to this or we all would be doing it. I use centerline with pennies wrapped in electric tape to weigh it down. I cut swiffer pads and glue the pad to itself. After each use I pitch it. I clean the track the first Saturday morning of each month.

One thing I would say too is not to over oil your axles or over grease the motors. Doing that keeps the track cleaner.

91% alcohol does it for me. Ever since I was a kid I've always loved the smell of the blue colored Life Like track cleaner. No harmful vapors that I know of. Always takes be back.

Since I have a lot of track in not the easiest places to get to, I finally after almost 30 years decided on looking at track cleaning cars. I settled on a CMX for $300. I also bought several extra roles of the cleaning pad material. I use Isopropyl alcohol for the cleaning solution. ( I was investigating using acetone until I spilled it on our kitchen wood top table. My wife said that was it for the acetone)) I have had good results but I do run the car changing the pads regularly until the pads start to look less dirty. The car does have some weight to it and the manner in which the alcohol is metered to the front pad is by a thumb screw adjustment on the top of the car. The second pad is the wiper. The pads a a little cumbersome to change each time but track cleaning is a necessity and like all things you get used to changing them. I hope this along with all the other old heads' experiences in here help you make a decision that helps you.

i was a 91% IPA user until....Please, read this article. I now use mineral spirits and results are great.

I read this thread a couple months ago when I was looking for a better answer. I have a layout with tunnels, and they are nearly impossible to clean by hand. Over the years I've used an old Lionel track cleaning car and a North East Trains car. The North East Trains car worked OK after I fashioned a shell to ride on top of it and add weight, but I didn't run it often enough and was not satisfied with it's performance. So, after researching here, I bought a CMX cleaner. I have found it works better than anything I've tried, and I'm very satisfied. The only thing better is elbow grease when I take the time and where I can reach the track on the layout.

Am glad to see that Wahl clipper oil is listed in GRJ's table of non-polar cleaners; I've been using it for some years now.

When I started this thread I was mainly asking about track cars, and there's been some good ones noted. I think however a "train" of track cars, at least 3, pulled by an engine is the magic formula, though am not sure if anything beats the old hand pushing a rag. But, if you can maintain track with cleaning cars, it stands to reason that major cleaning frequency would be reduced.

Access to this requires an OGR Forum Supporting Membership