Originally Posted by Mike CT:

There is a very good thread, 3 Rail scale forum, four pages. Click on the underlined phrase to link.

Very good info for Atlas cars with ready made pad holes. Unfortunately that thread is locked for some dumb reason. SO can't ask beginner questions. Like whats this KD delay feature?

Have you visited the Kadee website? I thought they provided such information, but can't remember.

There was a diagram on page 4 with what looks like 10 different KD couplers short/long shanks, short/long box, coupler above the shank, coupler below the shank. Confusing choices (all my hobby shop had was #805, take it or leave it, (but others could be ordered at 10 bags one type minimum).

I have used only #805 couplers for more than 15 years now, and have excellent results.

Another poster stated the new MTH have the KD mounting pads on trucks, whats do they look like?

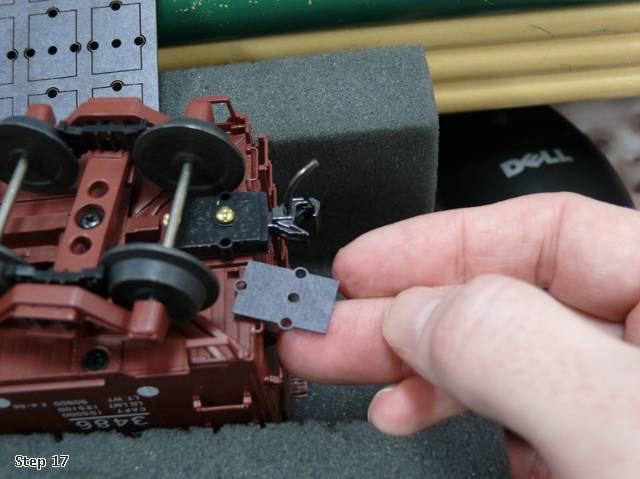

No. MTH has Kadee mounting pads, with the appropriate shim, on the FRAME of the freight car, i.e. NOT on the truck. The later MTH freight cars are set-up for body mounted Kadee couplers, thus one must remove the "claw" from the MTH truck assembly (since the truck is die cat, I simply break off the appropriate claw mounting arms).

Several of my cars cars have steel bottoms so do you super glue the coupler boxes onto the floor bottom?

No! With a metal underframe, it is always best to drill and tap 2-56 threaded holes for mounting the Kadee gear box assembly. I have only used glue, actually epoxy J-B Kuik weld, on one or two cars that I had planned to run only on the rear of a long train, i.e. just forward of the caboose.

Newbie question, questions.