Hi, I have to move and as such are tearing down my existing layout to move to the new location. I though I would take this opportunity to rewire and convert the whole layout to TMC and DCS. I currently have manual control using relays on some runs and TMC or DCS on other lines. All the tracks have soldered connections about six feet apart. I am thinking about star or run to home wiring instead of bus. I will be using Lionel 180-powerhouse bricks on all lines. so, the help I am looking for is which wiring configuration to use and how many Powerhouse Bricks. That is, is there a rule of thumb or methodology that I can use to determine how many Powerhouse Bricks per foot of track. I have some220 feet runs and I run both freight and lighted passenger configurations. Any thoughts or opinions would be greatly appreciated. thank you, Clarke

Replies sorted oldest to newest

Take a look at it this way. A 180 watt brick is about 10 amps at 18 volts Most dual (Two) can motor units draw about 1.5 to 2 amps in command, 18 volts. If they are sitting on the track, powered, with just lights on, considerably less. How many trains can you run at one time?? 2, 3, 4,....... Keep in mind the in rush current on initial power-up of all units, on live tracks, can exceed the thermal cut-out on a PH. Once on the current is less.

It doesn't require a 180 watt brick for each loop, or track section, or each unit/locomotive.

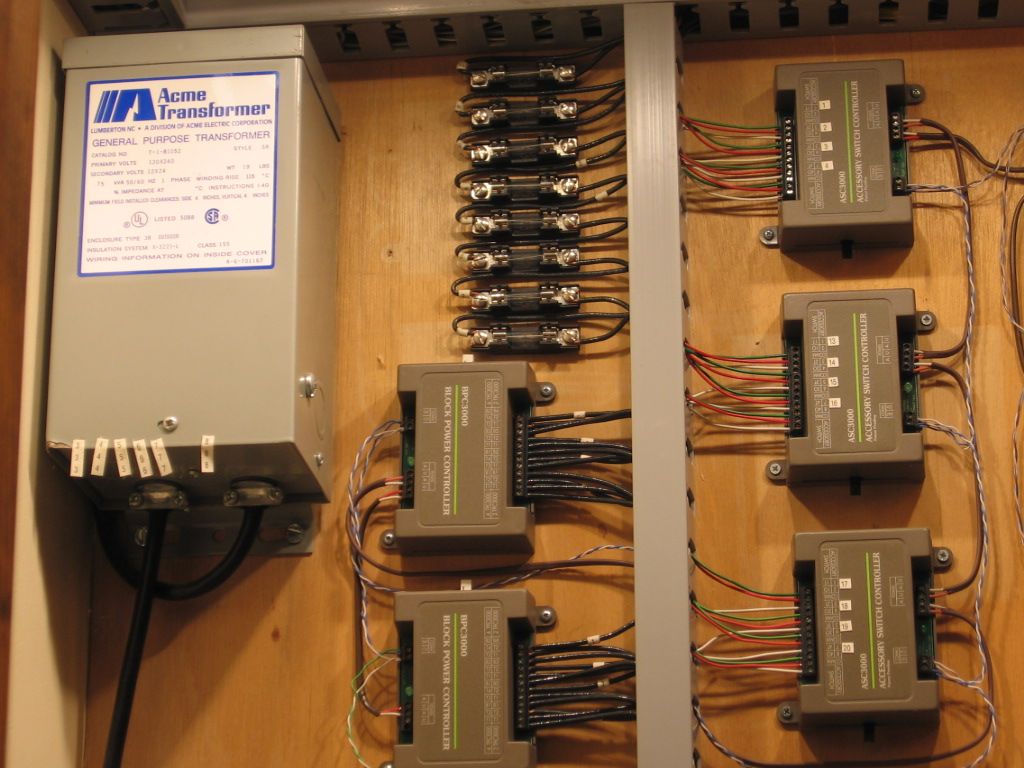

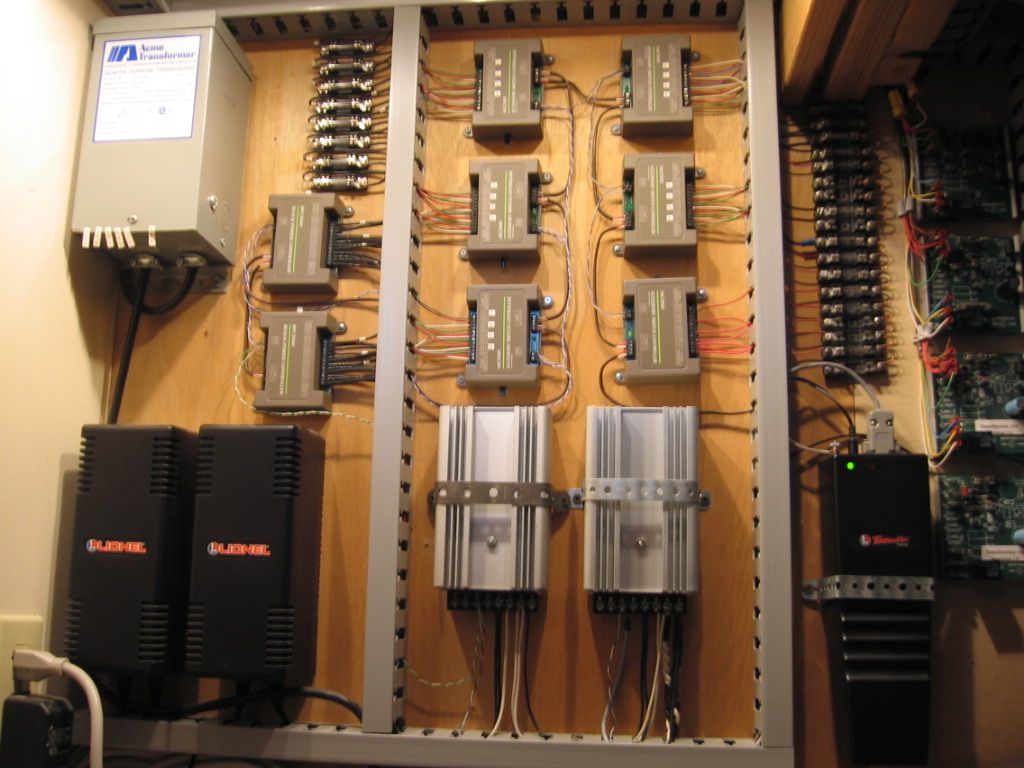

I power my small layout with (2), older, 135 watt bricks, paralleled together, (270 watts), (Lower left in picture) then the power is distributed to (8) power districts or track sections (Upper left in picture, next to the gray wire mold). Each power district, track loop/section is fused at no more than 7.5 amps.

I run command mode.

Thank you Mike for your response. I have been using the TMC direct connector as a circuit breaker. They have an internal switch for either 135 or 180 watt bricks. if two bricks are run in parallel, an idea I like, I assume the switch is set to the wattage of each brick and both bricks have to be identical. Say 135 if two 135-watt bricks are set up in parallel. Or can these lockons' not be used in a parallel brick setup. Also, would you please describe for me how you setup your bricks to be in parallel. Are you using any external type of circuit protection like an extra circuit breaker or in line fuse. Am I correct in that if a fuse is used it would still be about a 10amp quick blow. Regards, Clarke

MikeCT

Very nice job on the power panel installation.

CLARKESR posted:Thank you Mike for your response. I have been using the TMC direct connector as a circuit breaker. They have an internal switch for either 135 or 180 watt bricks. if two bricks are run in parallel, an idea I like, I assume the switch is set to the wattage of each brick and both bricks have to be identical. Say 135 if two 135-watt bricks are set up in parallel. Or can these lockons' not be used in a parallel brick setup. Also, would you please describe for me how you setup your bricks to be in parallel. Note the connector that is available. TMCC TPC Cable Set 6-14194 Note the cable/double cable attached to the TPC 400. The two low voltage plugs on the Cable Set (Pictured) are inserted in the low voltage cord ends of the PH 180's , above the Quad ,110 volt outlet, bottom right.

Are you using any external type of circuit protection like an extra circuit breaker or in line fuse. Yes, note the fuses pictured. Power from the Parallel transformers is routed from the TPC to (2) BPC's Block power controllers. Picture below.

Each BPC has (4) track circuits, a total of (8). From the BPC's track power wiring is extended to the (8) fuses, upper middle of picture, and then to the track loops. Fuse blocks pictured are from Grainger. Click on this link. These fuses block use standard automotive glass fuses available at auto parts supply stores.

Am I correct in that if a fuse is used it would still be about a 10amp quick blow. I use 7.5 amp fuses for each track circuit, seems to work well even with multiple engine consists.

Best wishes,

Mike CT

Understand that mike is using the TPC to parallel those bricks. It was designed to do that. The output of the TPC is what he sends to various blocks. The TPC is rated at 400Watts.

You can not parallel 2 bricks through a single lock on. The lock on is rated at 180W not 360. You can choose to parallel at the track via 2 lockons one for each Brick. But you won't have the same level of protection. As mike stated you don't need multiple power sources per block just good wiring to get the full Voltage along all blocks. Unless you intend to have multiple consist of AC motor engines on the same loop. That is when it is advisable to set up power blocks with dedicated transformers in phase but isolated with center rail isolation, so that these consist as they move along the loop only have one consist on a powered block at a time therefore a single transformer has only one engine to deal with. G

This consist does well with the 7.5 amp fusing and wiring as detailed. The five units are all powered. Click on the triangle.

A while back I expanded my test track so I could run my Lionel E7 ABA, all three units powered with smoke off, and I think 7 of my K-Line 21" passenger cars with Streamlighting. Power was through a TMCC Powermaster using a Powerhouse 180. That train would pop the PH's CB. I had to go down to 4 cars before it would run at low speed. (As gunrunnerjohn will tell you, if I replace the Streamlighting with LEDs results will be different.)

I replaced that power setup with a TPC400 and 2 PH180s and was able to run the ABA with all 8 cars plus some Weaver headend cars at speed; looked great. Unfortunately, this puts 20 amps to the track which could damage your equipment in a derailment. To prevent this, I use PSX-AC circuit protection set at 15.8 amps. This has a very fast electronic CB which so far has prevented any damage during any operator errors.

G's recommendation of power blocks is the way to go if each of your trains pull less than 10 amps. I go the 1 TPC/2 180 combo per mainline track loop because I have at least 3 consists that will push the 10 amp limit. Plus that is enough power to run multiple other trains on each loop. The PSX-AC is what is allowing me to do this safely.

How would parallel 180 bricks turn into 360 ?

In parallel, linked to a Track Power Controller[TPC] enables doubling the wattage output [180+180 PoHos]while the voltage remains @ max 18VAC.

Paralleled bricks usually turn into a welder! For 99.9% of operators, there are better ways to solve power problems that putting 20 amps of power on the rails!

gunrunnerjohn posted:Paralleled bricks usually turn into a welder! For 99.9% of operators, there are better ways to solve power problems that putting 20 amps of power on the rails!

Please expand this statement (Better ways) for the price of Two PH 180's

Thank you,

Mike CT

GGG posted:Understand that mike is using the TPC to parallel those bricks. It was designed to do that. The output of the TPC is what he sends to various blocks. The TPC is rated at 400Watts.

You can not parallel 2 bricks through a single lock on. The lock on is rated at 180W not 360. You can choose to parallel at the track via 2 lockons one for each Brick. But you won't have the same level of protection. As mike stated you don't need multiple power sources per block just good wiring to get the full Voltage along all blocks. Unless you intend to have multiple consist of AC motor engines on the same loop. That is when it is advisable to set up power blocks with dedicated transformers in phase but isolated with center rail isolation, so that these consist as they move along the loop only have one consist on a powered block at a time therefore a single transformer has only one engine to deal with. G

Is it a problem when a locomotive crosses from one power block to another and one pickup roller is in one block and the other pickup roller is in the other block?

Keith

Break the layout into power districts, there's no reason for that much power on the rails if the layout is designed properly.

Keith, there is no issue when you cross power districts if the transformers are phased properly and you are running the same voltage on all the power districts. Our club layout does this all the time, never an issue.

gunrunnerjohn posted:Break the layout into power districts, there's no reason for that much power on the rails if the layout is designed properly.

Keith, there is no issue when you cross power districts if the transformers are phased properly and you are running the same voltage on all the power districts. Our club layout does this all the time, never an issue.

I guess you never seen 4 AC Pulmore Dual motor diesels in a consist pulling lighted passenger cars. I seen a layout with 4 power masters in parallel per block. It works, but derailments can be fun. G

GVDobler posted:How would parallel 180 bricks turn into 360 ?

That is how it works. You have to sources of power and they share the load in parallel. If you parallel 2 ZW with both A and D to the track voltage stays the same but power(and current) available is additive. G

GGG posted:gunrunnerjohn posted:Break the layout into power districts, there's no reason for that much power on the rails if the layout is designed properly.

Keith, there is no issue when you cross power districts if the transformers are phased properly and you are running the same voltage on all the power districts. Our club layout does this all the time, never an issue.

I guess you never seen 4 AC Pulmore Dual motor diesels in a consist pulling lighted passenger cars. I seen a layout with 4 power masters in parallel per block. It works, but derailments can be fun. G

I haven't seen it, and I have no interest in trying to power it! ![]()

![]()

I have seen four Vision Line Big Boy's in a massive MU, but we couldn't smoke because we ran out of power. ![]()