Has anyone ever used metal tape to build up a pickup roller?

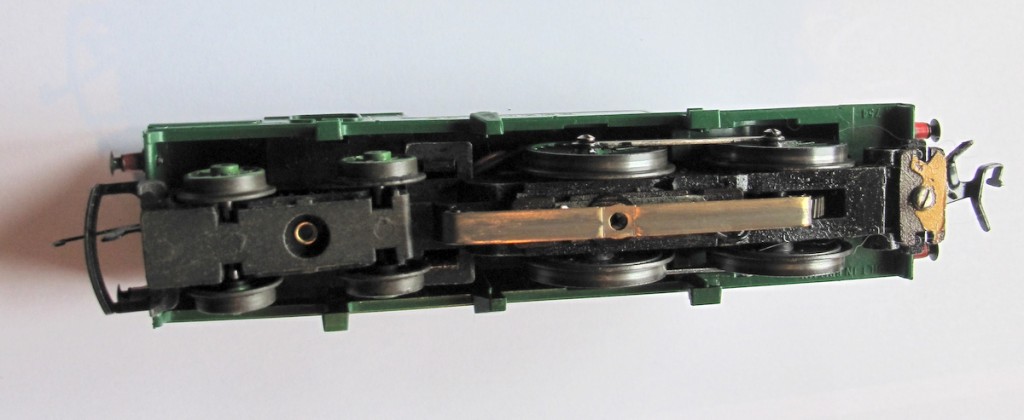

I'm working on this searchlight car and the bulb keeps flickering on and off. The wheels have been cleaned the rollers have been cleaned, the track has been cleaned.

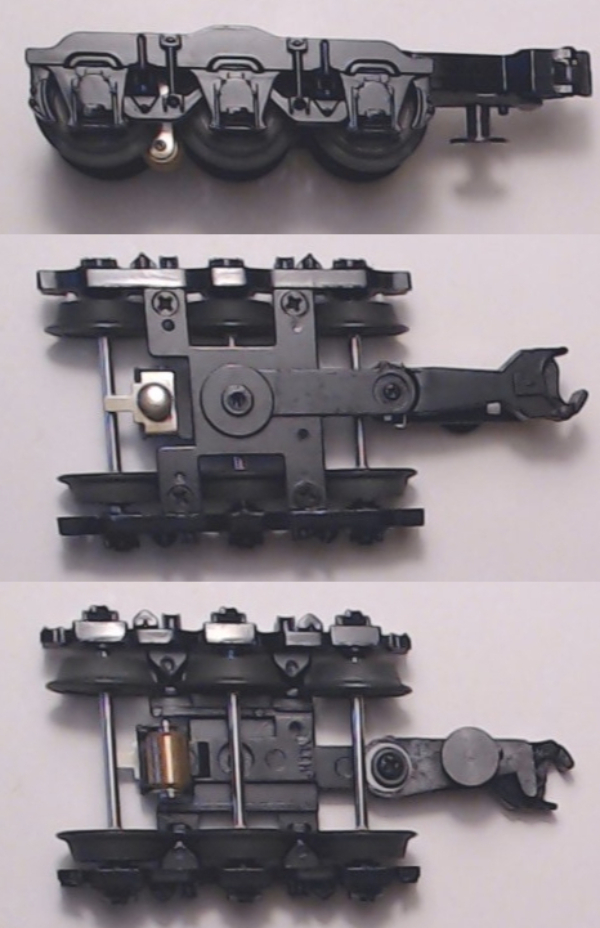

I've noticed there is so much slop in the trucks on the track that when you push, pull, press or lift the car in any direction the pickup roller separates form the track.

I would just replace the pickup roller with a larger one, but this is one of those permanent install types. No screws.

I thought if I wrapped the roller with a single rotation of metal tape, that would build up the roller to prevent separation.

Any and all thoughts welcome.