Just pointing it out in case the mods merge the 2 threads. FWIW, I would have started the new thread, but added a link to it in the current thread rather than asking the question in 2 different places. You might luck out and not get competing comments. ![]()

Update on my progress:

I laid the 3/4" plywood on my garage floor and laid my track plan on top of it to trace. After getting most of it traced and cut, I set up what I had to lay the track again (this time in the train room) and get the final plywood cuts traced.

Once I had all of my plywood cut, I laid it on homasote and cut that to the same size (WOW is that stuff messy!!).

Now I have both the plywood and homasote laid out waiting for the risers to be put in. I feel like I've made quite a bit of progress in a week, considering last week, the room wasn't even painted yet!

Attachments

Looks good Mike! Yes homasote is messy. Someone here recently mentioned using a blade that is more like a knife blade. I would agree that would be better, though I've never seen one. I tried cutting homasote many years ago with several passes with a utility knife. It worked, but was hard on the hands, and you have to be extremely careful not to stab yourself. I wouldn't recommend a utility knife myself.

There a 4" and 6" knife edge blades that fits t-lock jigsaws. The knife blade is great for foam sheets and homosote.

Nice work! You are moving along. That must feel good.

I have a question - did you put a dimmer on the ceiling pot lights? If you used the Tibetan sky, try shielding a bulb or unscrew one and check the impact on the color.

Carl,

Thank you for the reference. I am going to try those blades on my upcoming construction.

Mike,

I'm glad to see you pressed ahead in spite of the naysayers regarding access in your other thread. There may come a time when you wish you had listened, but I suspect that will be quite far into the future and who knows what will happen between now and then? You're making good progress and I guess the only comment I have is about the entry. Unless I'm looking at things wrong, it appears that you've opted to include the switch on your removable section. I'll be interested to see how that works out for you. I think I would have extended the decking to support the switch and opted for a smaller entry.

Mark,

I cut a couple pieces with a razor blade, it wasn't too bad, but I wouldn't have done the whole thing with it!!

Carl,

I wish I would've known/though of that yesterday! Oh well, its done now and I just have a lot of cleanup to do.

Dave,

Thank you. I'll have access to other areas through removable hatches, but I didn't really want to change too much to make the space easier to walk through. Unfortunately, yes... I did Include a switch in the walk-through. I'm interested in....if it is going to work too. If it doesn't I'll make the entry smaller and not include the switch, we will see!

mjrodg3n88 posted:Dave,

Thank you. I'll have access to other areas through removable hatches, but I didn't really want to change too much to make the space easier to walk through. Unfortunately, yes... I did Include a switch in the walk-through. I'm interested in....if it is going to work too. If it doesn't I'll make the entry smaller and not include the switch, we will see!

A man after my own heart, take a chance and prove to myself whether or not it will work. ![]() While it's not advisable, if the underlayment is done right, there's no real reason it shouldn't work. The hobby is full of compromises and this is just one of many. Hopefully it will work great and prove the naysayers wrong.

While it's not advisable, if the underlayment is done right, there's no real reason it shouldn't work. The hobby is full of compromises and this is just one of many. Hopefully it will work great and prove the naysayers wrong. ![]()

Cutting homasote???

Buy a top-quality DRY-WALL SAW. (You can find one under $20 - and worth every penny.)

Works like a charm!

Update 3/5/17

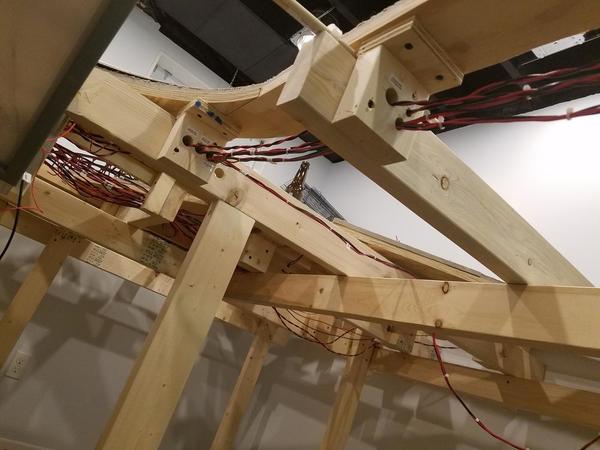

I've had the track laid over homasote and on the benchwork for a couple weeks now, but had to take a week or so off for a vacation out of the country. I have all of my power drops run using 16ga wire, but not soldered yet. I'm currently working on wiring the turnouts and operational tracks (which I need some help with, please see my thread asking the question about this) using 20ga wire. Here is what it looks like so far.

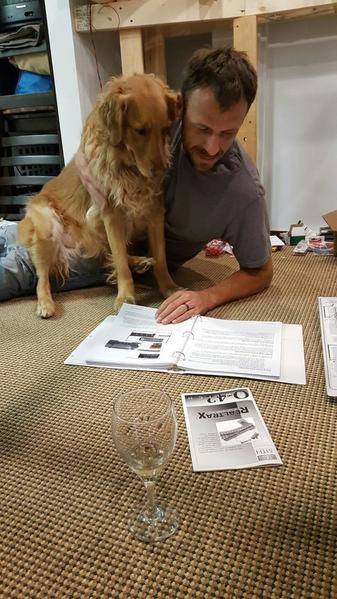

Oh, and of course my helper is right by my side as always.

Attachments

Well Mike, you can't go wrong with a dedicated helper like that! I like the neat wiring and the roadbed and track looks good from what I see. What plans do you have for a backdrop? Just blue sky on the walls.

mjrodg3n88 posted:

Mike...Not sure if you meant your "helper" was mans best friend there at your side...or the nearly empty wine glass in the foreground? Sometimes, when working on a layout, the latter works best...but not always!!! ![]()

Thanks Mark. I'll be adding a printed backdrop later, I've about spent my budget just on where I'm at today. I know it'll be a pain later, but my goal at the moment is just to have functioning rails! My favorite backdrop that I've seen is Chuck's.

Paul, ![]() I think my helper that night was both, HOWEVER..... we both passed out on the floor laying under the wiring.

I think my helper that night was both, HOWEVER..... we both passed out on the floor laying under the wiring.

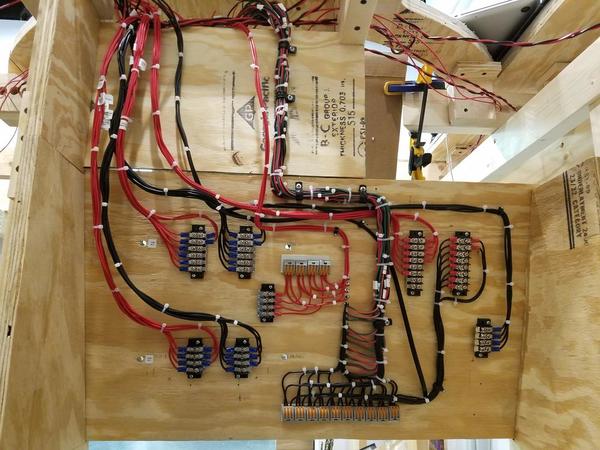

Update 3/8/17:

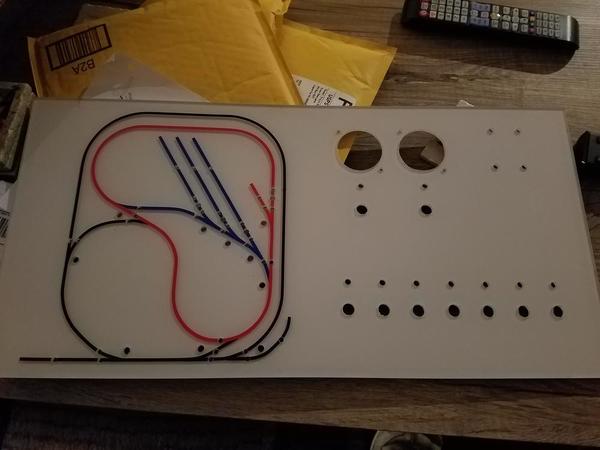

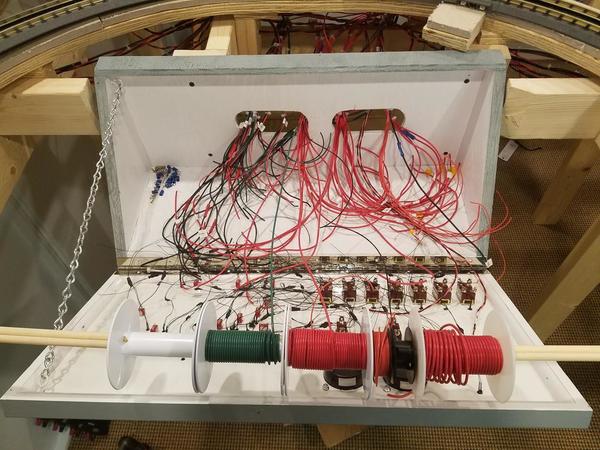

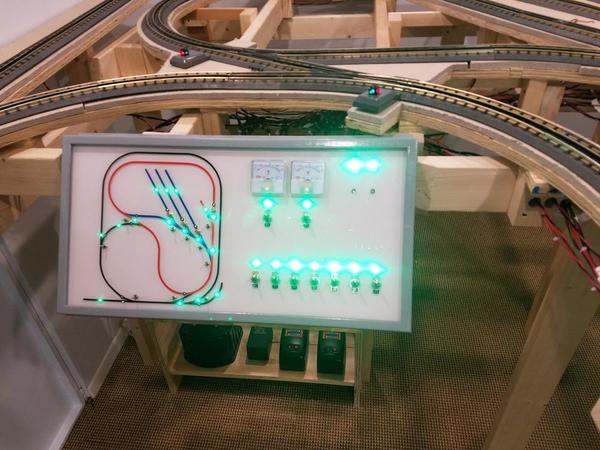

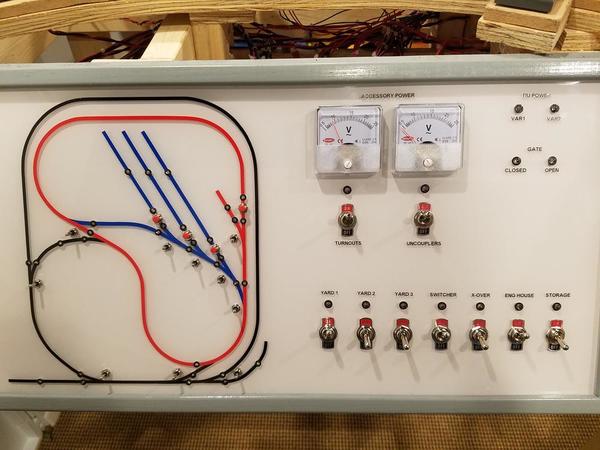

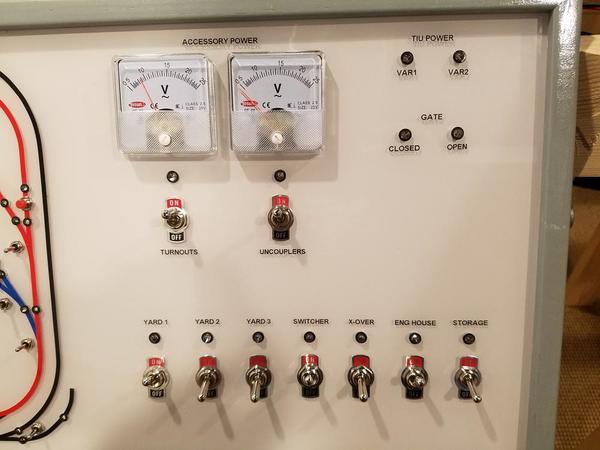

I finished some more wiring the other night, notably that for the turnouts (you can see the massive bundle of wires). I ran out of wire so I'm currently waiting on my delivery from Delcity which should be here today. While waiting, I decided to work on my control panel. This to me is sort of a big hurdle to clear (aside from the gate/door that I have to build) because other than running out of wire, this is what is holding me up. I decided not to include the NS, NW, SR, or Conrail logos. The reason being that if they got messed up at all, I would've been pretty angry, so I scrapped the idea. The whole control panel creation was fairly easy, its the wiring that is going to be "fun." I watched Laidoffsick's Youtube video showing to paint the back white and use pinstripes for the track plan.

Anyway, here are the pictures:

Attachments

A little more progress over the weekend. The good news is that there should only be a couple more wires that need to be added behind the TIU and AIU. After that, I'll use cable nail-in clips to further organize and line everything up. Before soldering and making the connections in the control panel, I have 3 more turnouts to run wire to and will then twist the common and hot wires together that run to the 4 uncoupling tracks. I've also starting adding my power and running that wire, which is about 90% complete. OF COURSE you can see that I had my helper. Its really hard to believe that only 4 weeks ago (February 10th) I started my benchwork (and of those 4 weeks, I was out for an entire week on vacation.)

I wish I would've used black cable ties so it'd look a little neater, but this is okay I guess.

Most of the holes that the wire runs through are labeled, a couple are missing, but I'll fix that eventually.

This wiring will look much better when I'm done running wires here. It will also all be labeled.

My supervisor.

Attachments

Mike it is hard to believe the progress you have made!! Ah to be your age again! LOL. I have to go slow because of helping 4 elderly relatives, both Matt daughters from time to time, and just being too tired at the end of the day!! I am very happy to see your progress, and look forward to seeing trains running!

Mike - I really like what you came up with. Wish I had seen your 8x10 before I started building my new 8x11 (lost my basement space to my kids but gained bedroom....long story). Mine is similar, with an outer loop mainline and a connected inner loop. All interior space is yard and a city. I'm going lite on scenery. Because of already-expected boredom, I'm adding an elevated level, so at least I'll have the ability to run three trains.

Great job. Makes sense that you're a mechanical designer. Great use of space.

That is great progress and it all looks very nice too! I think your track plan and everything has turned out very well. Trains will be running before you know it.

I would check with your helper though, looks like something may need attention down on the power shelf. ![]()

Looks great Mike! ![]()

Thanks, Mark. It has definitely surprised me how much progress I've made. This wiring is insane though, it is without a doubt what has taken the longest so far.

Raising4daughters, thank you for your kind words. It took me quite some time to come up with this design. For a while my design was two simple loops with an inner yard. I'd move stuff around, but couldn't get away from the loops. I beat my own stubbornness and changed the inner loop from O54 to O42 and I was able to change things up.

RTR, thank you. Hopefully I'll be able to run them soon! You're right and she must have figured out what it was because I walked away for a minute came back to her cleaning off the Z500 with her tongue...

Thanks Doug, (and for the awesome Control Panel video that you made.)

Update 3/14/17:

Last night I was able to completely finish the wiring behind the TIU and AIU. (I hope its complete anyway, I'll find out if I missed something when I power up the system...). Next up, soldering to the track and making all of the wiring connections at the control panel, turnouts, and operating track.

Attachments

This past weekend I was able to finally apply power to my setup (without any trains). Had a few things messed up, but they were veryou minor. I programmed into my DCS remote and tested all of my switches and uncouplers. This was the very first time I was ever able to experience the control of them through the remote. Man this is going to be fun! It was neat to stand back and watch the control panel lights swicth.

After about 5 minutes though, smoke from the KW. I immediately took it outside. Thought about scrapping it, but I read some of the threads on here and talked to the guy at my LHS. With that I messed with it last night and the arms that the rollers are on were really bent, causing parts of them to touch the coils. I straightened them out and made sure only the rollers were touching. After about 15 minutes, still no smoke. I think I may be good to go.

Also, I now have the frame for the door up. Now I have to cut the track on the hinged side and connect the power drops to the door and pushbuttons I have going to it.

Attachments

Woah!! The source of the smoke problem! You are now an electronics expert!!! ![]() That's what they always said at work; see it once, now you are an expert!

That's what they always said at work; see it once, now you are an expert!

It is shaping up really well, Mike!

Mike the ME:

Your attention to detail in dressing-up the wiring pathways is a marvelous example for neatniks to follow and a gentle indictment to hobbyists whose under-table wiring may look like an explosion in a spaghetti factory. Your control panel is ultra-cool.

Your wiring plan is an inspiration to me since I'm now approaching the electrical phase of my emerging 15x19-feet L-shaped home layout. It will include circuitry for both Lionel (TMCC) and MTH (DCS) control systems for operating trains of both brands.

With appreciation for the inspiration!

Mike (ritrainguy)

Mark Boyce posted:Woah!! The source of the smoke problem! You are now an electronics expert!!!

That's what they always said at work; see it once, now you are an expert!

It is shaping up really well, Mike!

Thank you, Mark. Haha, no expert here, just did some research here on the forum and sort of guessed what was being talked about. I actually think it was GRJ's suggestion years back!

Mike H Mottler posted:Your attention to detail in dressing-up the wiring pathways is a marvelous example for neatniks to follow and a gentle indictment to hobbyists whose under-table wiring may look like an explosion in a spaghetti factory. Your control panel is ultra-cool.

Your wiring plan is an inspiration to me since I'm now approaching the electrical phase of my emerging 15x19-feet L-shaped home layout. It will include circuitry for both Lionel (TMCC) and MTH (DCS) control systems for operating trains of both brands.

With appreciation for the inspiration!

Mike, thank you very much for your kind words. I'm just super anal about things and when it comes to wiring, neatness. Even when doing wiring in my house, the 12/2 wire has to be flat and not twisted as often as possible. Good luck on your your L layout!!

This past weekend I did quite a few things.

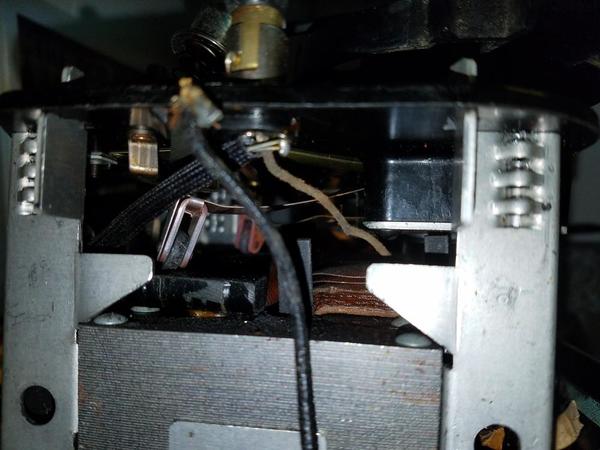

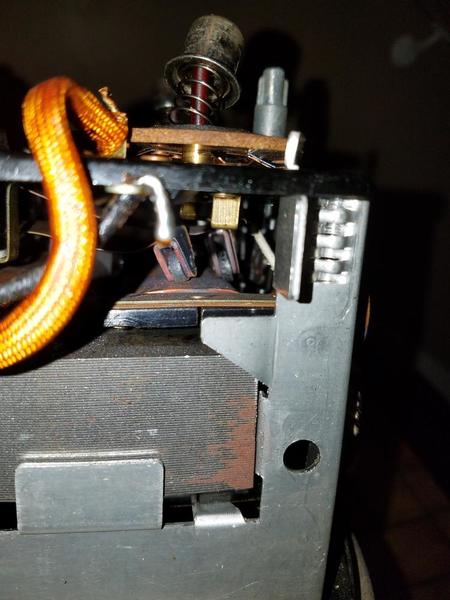

First, I was having issues with one of my turnouts. When I’d try to flip the switch, it would buzz and not switch. I read on here somewhere that one of the outside rails in the “V” could be touching attached ground rails so I taped them off, still the buzzing and not switching. Assuming I had a bad switch, I figure eh, what the heck, I’m just going to run a train around a few times and worry about that later. Mistake. The train went over it without any problems for a while, then it happened. The engine sparked at the track, shut off, and I smelled something burning. Shut everything down, pushed the engine to another location, fired it up, whew, it wasn’t the engine burning. Okay, I figured I burnt the switch motor since it wouldn’t work anymore. When the engine would go over it, it would briefly shut off until it hit the next piece of track. Finally I took it apart and found the issue that caused the buzzing and also what burned and why the engine was shutting off. One of the ground contacts underneath had come apart and one of the 4 copper ribbons under that “slide” had been burnt through. Of course that had to be the one for power to the center rails. I was about to throw in the towel, but figured, what the heck, if it’s junk already, I can’t hurt it. I soldered the ground contact then pulled the bad copper ribbon out and replaced it with 4 single strands of copper from 20 gauge wire. The trick was, I laid the strands flat, held them in place near the end, twisted the protruding end, and soldered it. I did this to both sides. After that, I laid it right where the copper ribbon was and soldered it to the wire at each side, covered with electrical tape, and then reassembled the entire thing. Tried it out, success! No more buzzing or engine shut off and it switches flawlessly. Note, the pictures below are not mine. I google searched and they linked back to posts here on the forum.

Photo Credit: Railhead53 - Circled in green is the ground contact that separated.

Photo Credit: Pennsydave - Circled in purple is where the ribbon was burnt (seeing this now, I could've just done what has been here.)

Once that was fixed, I figured I’d try out the Norfolk Southern SW1500 PS2 switcher that I bought from someone on FB. Well, that was about par for Friday night. Check Track, Engine Not found, perfect. Searched here on the forum (as I always do before asking questions) and found the possible answer, the battery. The next day I went down to my LHS and bought a BCR. Now, I know everybody talks about them, but I have never used one so didn’t care much. Plus, I’m terrified of ruining the engine electronics somehow. Anyway, I took the old battery out, put the BCR in, put it on the track, waited 1 minute, success. Now I have the BCR bug.

Last night I replaced the 9V battery in my Southern F3 ABA PS1 with a BCR I bought a few months back. Man those things are great and so easy to replace!! Before I put everything away to start on the train room, I was running my RK Allegheny 2-6-6-6 and noticed squealing when the smoke unit was on. Of course I did my usual search here on the forum and found the issue. Took the shell off, took the smoke unit apart, oiled it, put it back together, another success!!!

I had one more thing to complete which I was sort of dreading, adding the latches to my door. I bought two spring plungers from McMaster-Carr and wasn’t sure they’d work how I intended. Last night I went for it, recessed them into the wood, closed the door, and yet another success!!

After that, for the first time on my layout, I was able to run some trains, and all I can say is this is fun!!

My only issue now is that I have WAY too much rolling stock. I’ll be posting in the For Sale Forum at some point.

Attachments

Way too much rolling stock! Don't we all! LOL

Its all looking good Mike!

**Update 4-18-17** With Videos.

I just realized I haven't updated this in a while (just have been posting in What did you do on your layout today?), although I haven't really done much. Since my last post, I have glued the Homasote down (with wood glue), painted it a tan color to prevent it from absorbing moisture and warping, added foam between the Homasote and track (to quiet the sound of the Realtrax), and added latches and labeling to the control panel. Another thing I did was add push buttons to the gate/door jam for two reasons; one being to kill the power to track on each side if it is open, and two, to operate the indicator LED on my control panel. If the gate/door is open, there is a red LED that will flash and if closed, a solid greed LED will be on. I also replaced the simple on-off light switch with a nice dimmer and wow does that make such a difference in the train room!

For the labels, I used a label maker with black ink on clear tap, then trimmed as close to the text as I could

The top push button is a (on)-off-(on) for LED control and the bottom is a simple off-(on) for track power control.

This is the foam I used for insulation under the Realtrax. Frost King AC Weatherseal from HD. I cut this into 4 strips, meaning instead of it being 2-1/4" thick, each strip was about 5/8" thick. It seemed to work pretty well too.

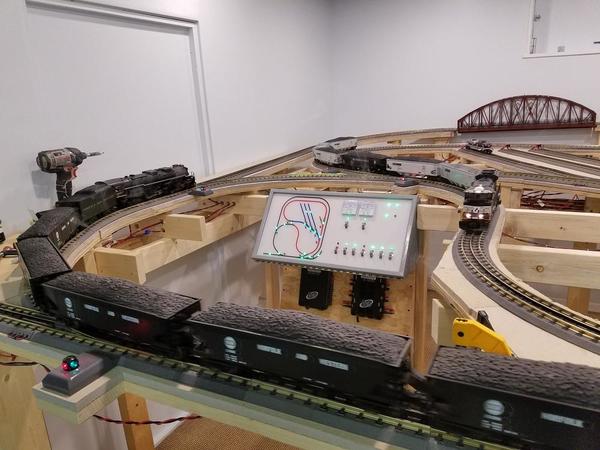

The latest picture of my layout. I doubt I'll be doing much more to it until the fall.

Another thing I did was move all of my train stuff back into the room from the garage. As you can see, I put my wife's shoe problem to good use with the boxes.

Below is another vantage point from the room.

And videos if anybody is interested:

Gate/door operation:

Running trains:

I have the Southern F3 ABA that goes with this set, but I wanted to see them behind the NS Heritage Unit

Attachments

Mike,

You have really made good progress! The gate works real slick!! Looks good!