Hey All,

I just got my holiday trains setup, and I'm having a nightmare with 2 of my trains and pickups. I replaced probably 6-8 sections of MTH realtrax track, did electrical testing, etc. I also have a handcar that runs fine on everything. The first issue is with an F-7 B&O PS3 from MTH. I'm attaching a photo where on one set of the pickups one pickup sticks down really low, and the other pickup keeps getting stuck in an up position. How easy/complicated is that to repair? Can I simply unscrew the old pickup and replace with a new one?? When I manually pull it down, the train runs fine until it goes over an operating track section - after that, it stops on switch tracks (my guess is the operating track pushed the pickup roller up to the "stuck" point).

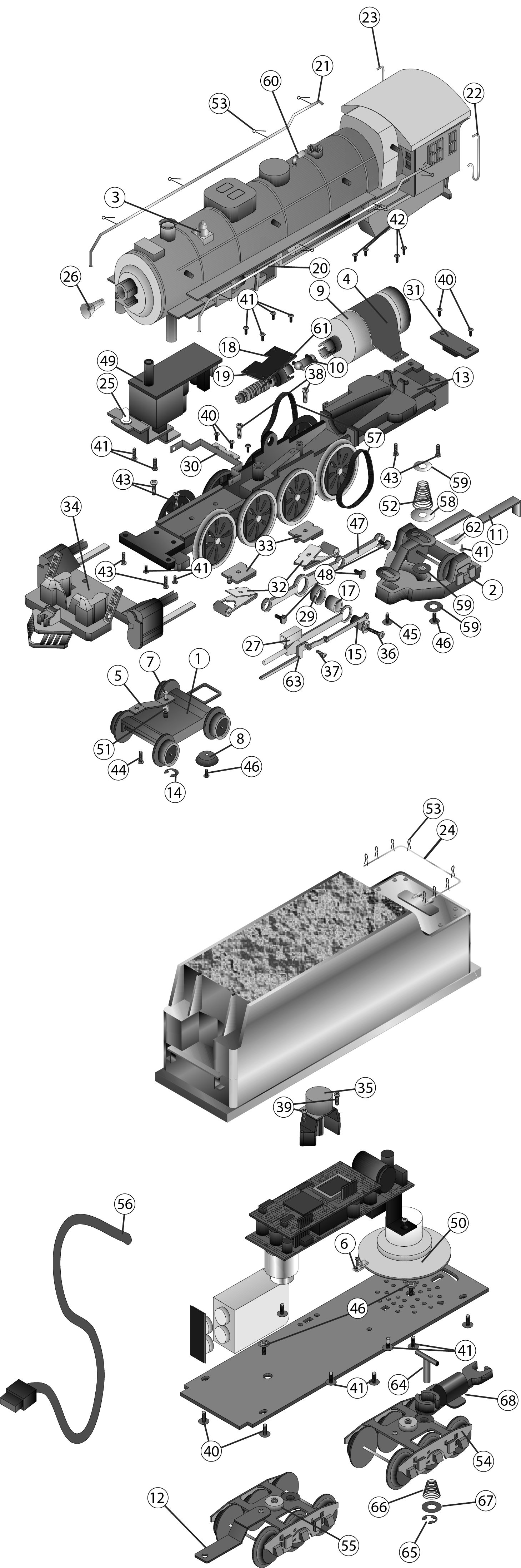

The other is this Mohawk Steam Engine from MTH (https://mthtrains.com/30-1834-1). I'd say it has never run great, but I'm wondering if one of the pickups isn't even working? Is there a good way to test that?? Last year I got it to run pretty consistently. This year, it will barely move an inch and then just shuts down. There has to be some sort of electrical connection issue. Any suggests would be greatly appreciated. My 4 year old engineer has been very disappointed so far this Christmas!! 😞

Things I've tried:

- Replacing track sections and checking with a multimeter

- Oiling everything

- Using WD-40 contact cleaner on the rollers and track to try and clean everything (https://www.wd40.com/products/contact-cleaner/)

Thanks, again, for whatever help you can offer!!

Gratefully,

Seth