I have a layout with MTH RealTrax. You MIGHT be able to, provided you use some sort of resistance soldering unit to provide the heat. Heating with a regular soldering iron could prove quite tricky. Due to the physical size of the rails, you would need a bigger unit, and be able to get on & off of it really fast, then immediately hit the joint with a damp sponge to kill the heat. Believe it or not, the newer track with the formed N.S. sheet metal rails would probably be easier to solder, as there is less mass in them that needs to brought up to the proper soldering temperature.

Also, you would have to do some trimming on the plastic roadbed where the joiners would go. Not a big deal though, at least in my opinion.

As a long time N-scaler, I've soldered a LOT of N-scale track joints. I can even solder feeder wires to the sides of Atlas code 55 track, anywhere/anytime/anyplace, and NOT melt the plastic ties or tie plates.

But without a resistance soldering unit, I think I'd still be hesitant about attempting to use soldered track joiners on RealTrax with a regular soldering iron.

But without a resistance soldering unit, I think I'd still be hesitant about attempting to use soldered track joiners on RealTrax with a regular soldering iron.

What I did instead on my Scaletrax, was solder feeder wires every 3 feet or so to the copper connectors under the roadbed. Then tie in to the buss wires under the layout. I have zero problems with electrical contact, but I'm just running strictly conventional right now - no DCS or any other command control that sends signals through the rails.

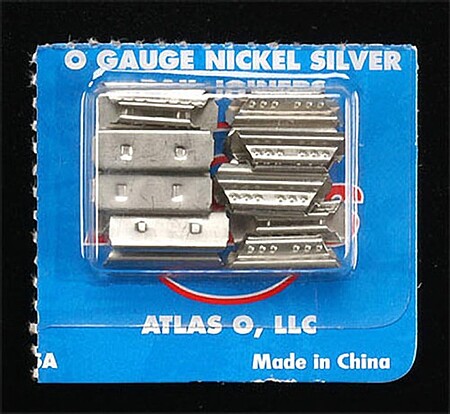

Actually, if I can pick up some rail joiners at train show sometime, I might just do that and give soldering a try on a few spare pieces of track. It would be interesting to see if it's doable.