That makes plenty of sense to me; good "point/counterpoint"👍...Despite a pile of little facts gathered above, the most important one, we tend to skip right over in our search for a singular "universal answer" is that there usually isnt one answer......"Milage may vary"

The drive wear from weight could be a reflection of it's pulling capabilities and wear expectations doing it too. You do have to add something to the pull wear expected to compensate for the downforce, inertia & momentum, but I wouldn't have really thought 2r O drives be that sensitive in gearing.

I like dry brushes, but do not to dry out metals of oil totally. The armature gaps collection of brush dust can bridge faster if the areas are too wet. I think grease having more "body" is an unwanted filler here. I can see a wipe being beifical, but I think dry overall is more benefical to the flow of the gaps expelling excess dust/air (with centrifugal force...this is the hvac airflow part of me thinking too) With more open area brushplates, nice plates, and harder brushes, the build up becomes less of an issue... and it's a case by case, but I have 3 motors of different brands with penchant for bridging gaps with dust. Brush wear doesn't seem abnormal either.

I had 400lbs in three young dogs, now down to two 150lb dogs end up here a few years ago (Im that sucker) I'm in a "dust bowl", in my eyes, for about another 4-8yr and can't really compare my track cleaning needs to most folks or even my own past. Too soon maybe..?

I think it's clever how the graphite is being used here. I keep thinking there are other places in the hobby this could be applied well. The only thing I ever really did with block graphite was mig weld small gauge metal on it's no-stick surface; a backer (you can lay a practice puddle of molten metal alone, without any subject metal to attach to ). I never got around to trying it with any kind of soldering. Might not even have the brick anymore. Tried anything like that?

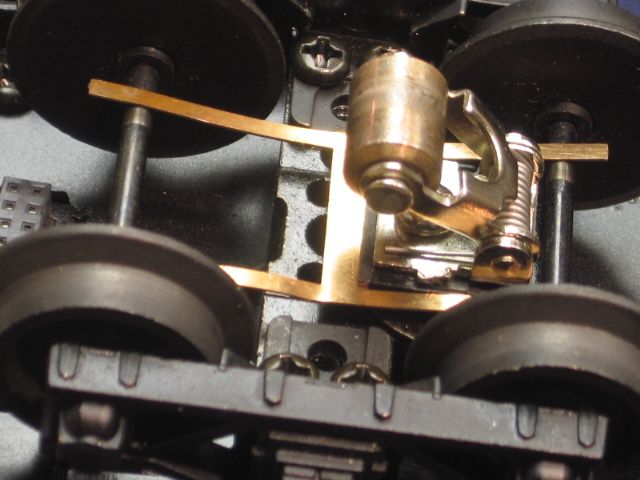

Im not a fan of wipers. I had better luck with plungers. But I wonder if a contact pad wiper is ever used? I came across 1 N gauge using them and they seemed great. They were basically like the brush arms on a small gauge moto, or the point arms of a small relay. Thin graphite points that have a boss on top held in place against the wheel with arm pressure, point simply seated in a hole in the arm. I've been thinking on axle contacts this might be a larger imporvement over plain arms and Im now kinda hunting my junk mentally for a large set from a dead motor I might adapt to a problem pass. car.

As active runners, I don't think we go long enough without some cleaning and re-application to worry too much about oil varnish build ups. Wood ties might be reason to keep some rails dry.