Originally Posted by CWEX:

Just out of curiosity, what would the welds in the steam chest have to do with it? I can't imagine that they wouldn't have ground down the welds after welding was completed.

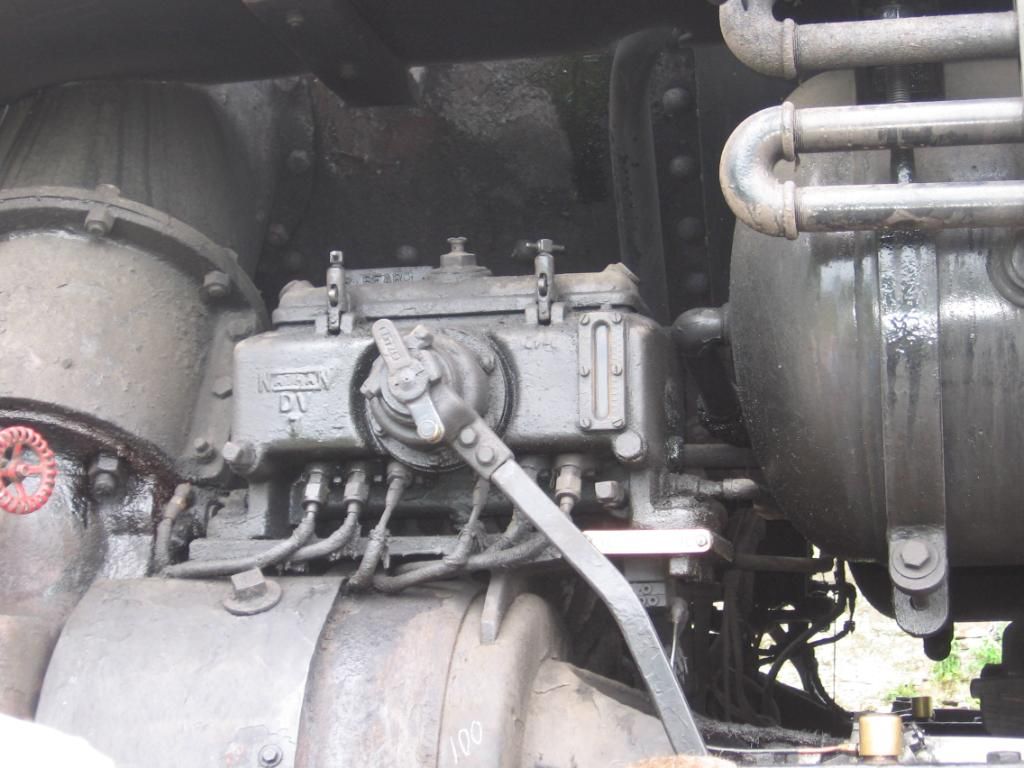

It has nothing to do with grinding down the welds. If the original damage moved the valve and cylinder assembly slightly fore or aft, it would affect the valve timing. Even 1/64" in this area would make a big change.

However, given that the engine is so badly out of TIME, I suspect one of the eccentric cranks is out of position by a degree or two. If it was just one of the valves out of position fore or aft, that would affect the squareness (even volume of all exhaust beats) of the exhaust, but not the timing. The 765 ran this way for several years in the 90's. Her exhaust was evenly timed, but one exhaust beat was louder than the rest. In this case with the 734, we've got both an "out of time" situation and an "out of square" situation.

I'm sure that when the 734 goes down for her 1,472 day overhaul, the WMSR crew will take care of this.