As you people receive your new switches and install them, please let as know how they worked. Thank you. I'm hoping they work great.

FedEx shows mine to be delivered tomorrow.

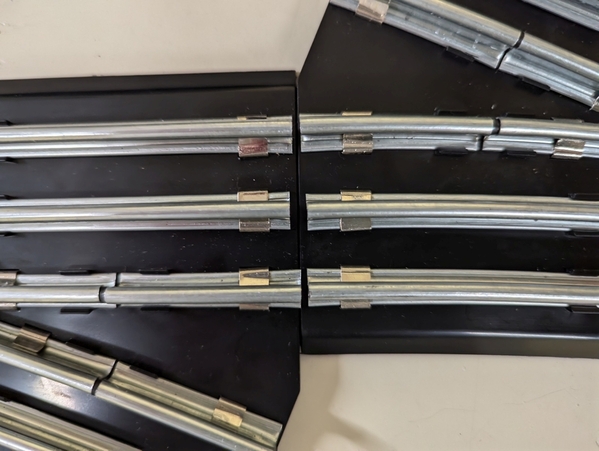

If they ever make them in 31" curvature, I'M IN!

- walt

Walt, I'm sure they will. They will go well with their tubular track.

I have other pictures, but this one tells alot... Need more QC. I should point out that this would be the junction between two blocks so a fiber pin needs to go on the center rail. So scratch that idea/location.

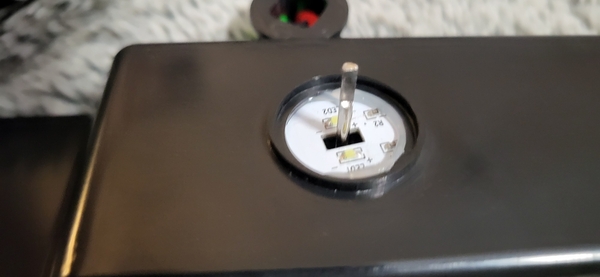

This shows the lantern does not fully rotate 90 on the diverging path. There is probably some gear some place that needs more teeth or something.

K-Line O72 SuperSnap is 14.5" on the straight route, these are more like 14.25" . Maybe I can replace some 30" straight somewhere it does not matter to get some run time on them.

Attachments

I replaced two O-72 curves with the switches, since it was easy and usually the curved path has more trouble. An Atlas caboose snagged somehow. A Lionel SD70-M (??) went thru once, and then on the second time it derailed. I see arc marks on the diecast frog. The diameter is not held well, some times the track pin slides unhindered. One pin slid all the way to the pinch point and interfered with the moving rail.

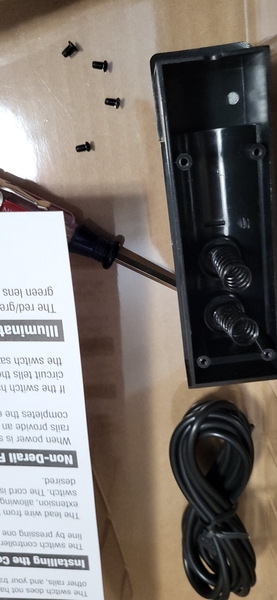

Can these be opened up (without destroying them) to see the wiring and switch mechanism?

funny there are no holes in the switch controller to see them.🤔

@RadioRon posted:Mr. C., thanks for those interior photos. Somehow seeing the "guts," especially with all of that plastic, does not inspire confidence.

I do not see any issue with the use of plastic gears in a situation where there is virtually no load and the length of travel is minimal.

The switch is only moving a small piece of track back and forth of about 1/2 revolution of the gear along the rack.

As long as the plastic rack and pinion is not soft a soft plastic material, it should last a very long time before wearing out.

Why induce the use of metal when it is not needed at an additional cost?

Conversely, a very cheap metal prone to zinc rot could have been used instead - would you have been more confident in the performance of the switch?

I think not.

Dear Menards, PLEASE add see through plastic caps on the switch controllers so we can see the red and green indicator lights. Thanks and keep up the good work!

Just saw @ericstrains.com video on these. As a lover of tubular track, here are my thoughts and observations.

First off, kudos to @Menards for offering a new item and thanks to Eric for buying a pair and posting a review.

While this offers a way for new hobbyists who might be getting introduced to trains from a visit to Menards to build a layout, I have a few concerns.

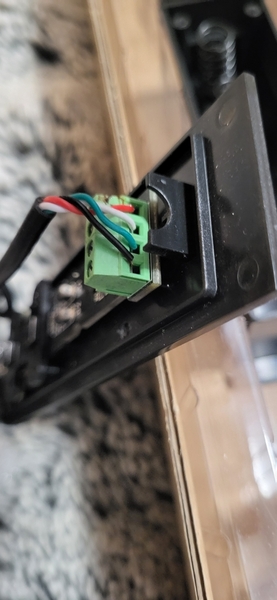

1) It appears that the switch motor can only be mounted one way. Some track configurations require that the motor is mounted on the outside.

2) The wiring uses a special connector. This makes it difficult to attach the controller if one needs a longer wire. It also does not appear to allow for the use of other methods (such as push buttons on a panel) to control the switches.

3) The switch motors do not appear to be serviceable by the owner.

4) Price. While $60 is not unreasonable, functional used tubular switches can be obtained for much less money, and they can easily be cleaned and repaired if necessary.

@Mr. C. posted:

Mr. C., Thank you for the great set of pictures inside the Menard's Switch and Controller. It's good to see that these switches (at least the initial run of them) appear to be serviceable. It also appears that the side pod where the lantern and remote cord are attached could be potentially be reversed to the other side of the switch (they appear to be separate assemblies and the main assembly looks like the terminals are on both sides). Can anyone verify they're reversible?

Also thank you to @ericstrains.com for the review.

Here it is:

Please let us know how your Menards "O" Gauge switches worked? Did they work perfect or were there issues?

The switching design looks far more robust that Lionels design, but

it's still a rather large "thing" hanging off a turnout that's harder to conceal under lichen.

Maybe a big switch house can be used to hide it; or some large 3D printed something or other!

@AlanRail posted:The switching design looks far more robust that Lionels design, but

it's still a rather large "thing" hanging off a turnout that's harder to conceal under lichen.

Maybe a big switch house can be used to hide it; or some large 3D printed something or other!

My guess is that most folks who use tubular track aren't worried about prototypical appearance. Main issue is finding space in a way that doesn't interfere with other tracks.

Since there's often a need for maintenance with tubular switches, I leave mine accessible.