All:

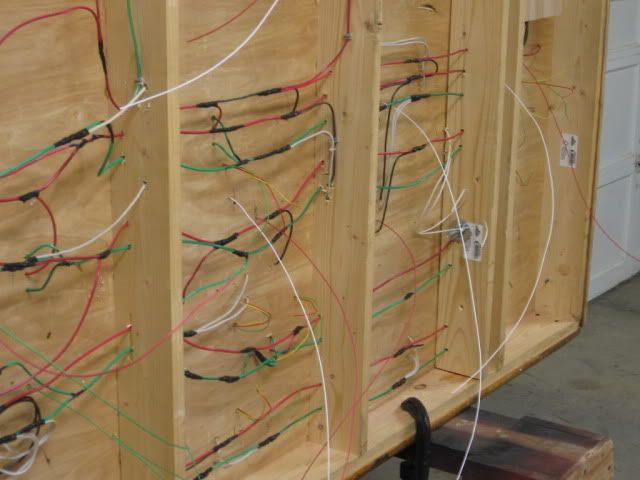

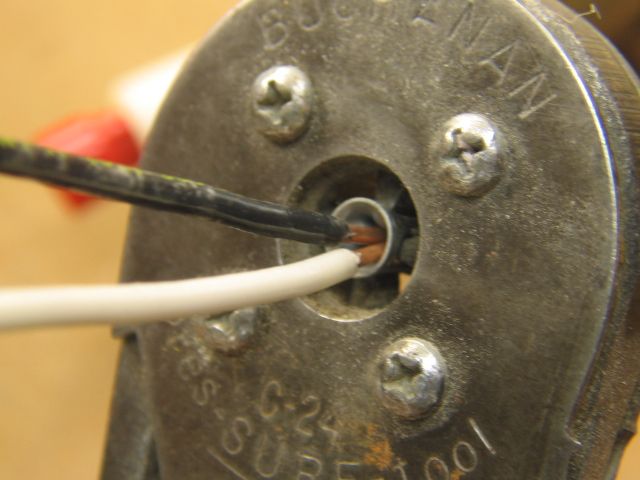

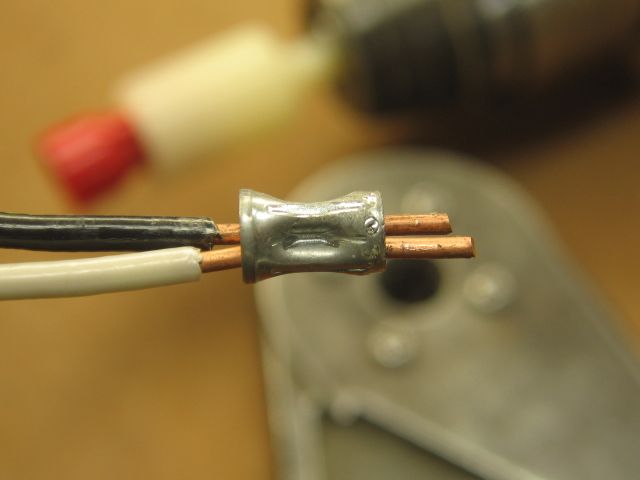

I think I'm done with Euro-style terminal blocks, maneuvering under the layout to hold wires in place while I screw them in place, and trying to figure out shoddy connections. The thought of making over 1,000 of these types of connections makes my head spin. ![]() I've read the previous threads on these connectors and want to give them a try, but have some specific questions.

I've read the previous threads on these connectors and want to give them a try, but have some specific questions.

- How well do these work with small wires like those used in the Z-Stuff components, e.g. DZ-1008 relays & DZ-2500 switch machines? I believe these wires are 22/24 AWG and 24 AWG, respectively. What model of connector would you recommend for this purpose?

- Do these connectors come in multiple configurations? By that I mean, can connect multiple wires in the same housing, like the Euro-style terminal block shown below?

- How do you mount these to plywood bench work? (I hate dangling wires).

Thank you!

George