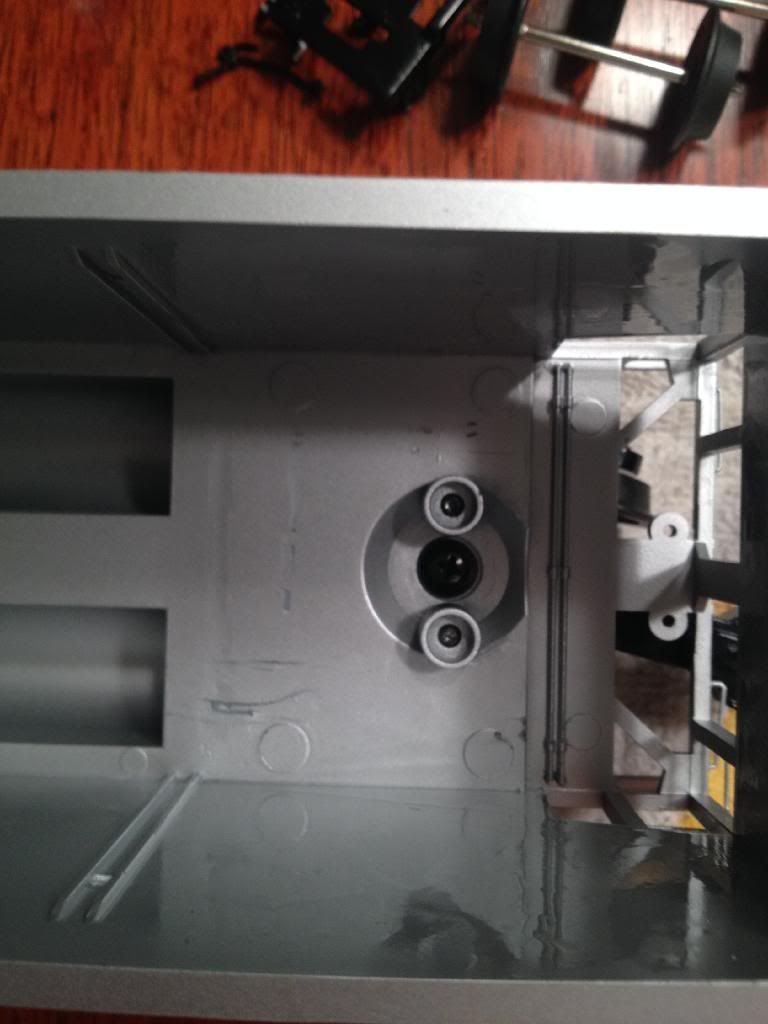

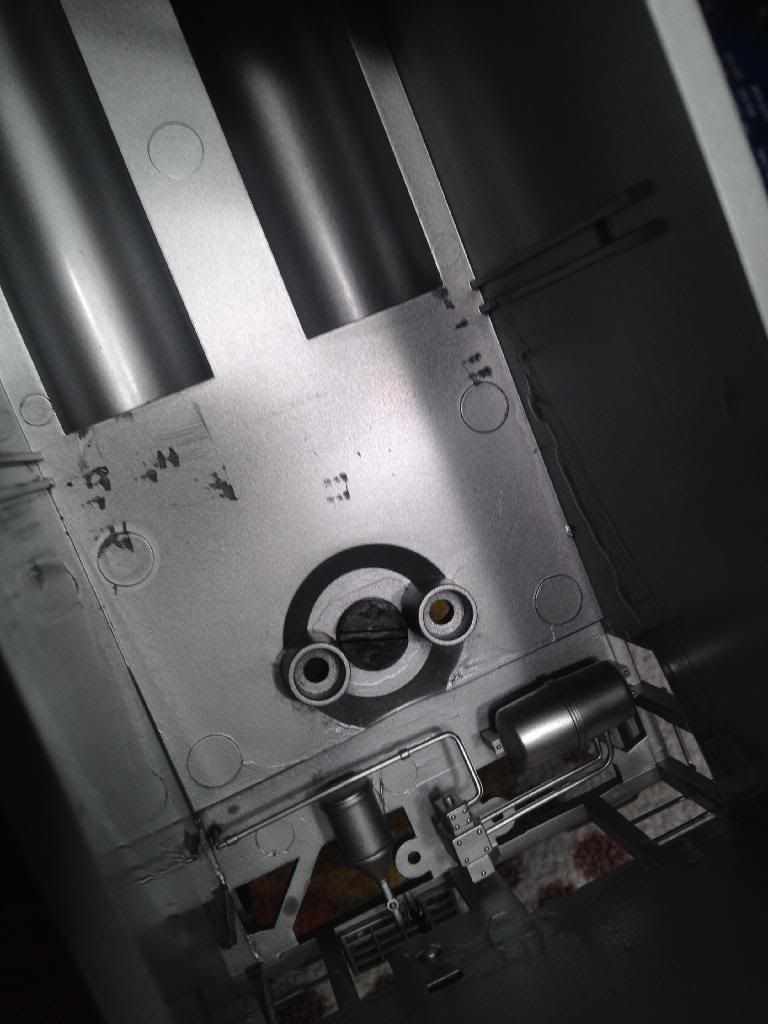

Ok...I feel like a dummy after almost ruining one of my cars. There are in fact 2 screws that hold the sloped ends of the cars in. They are extremely well hidden directly above the truck bolster, you can not see them looking horizontally under the trucks because they are recessed, and you have to rotate the truck until the coupler stops to get to them:

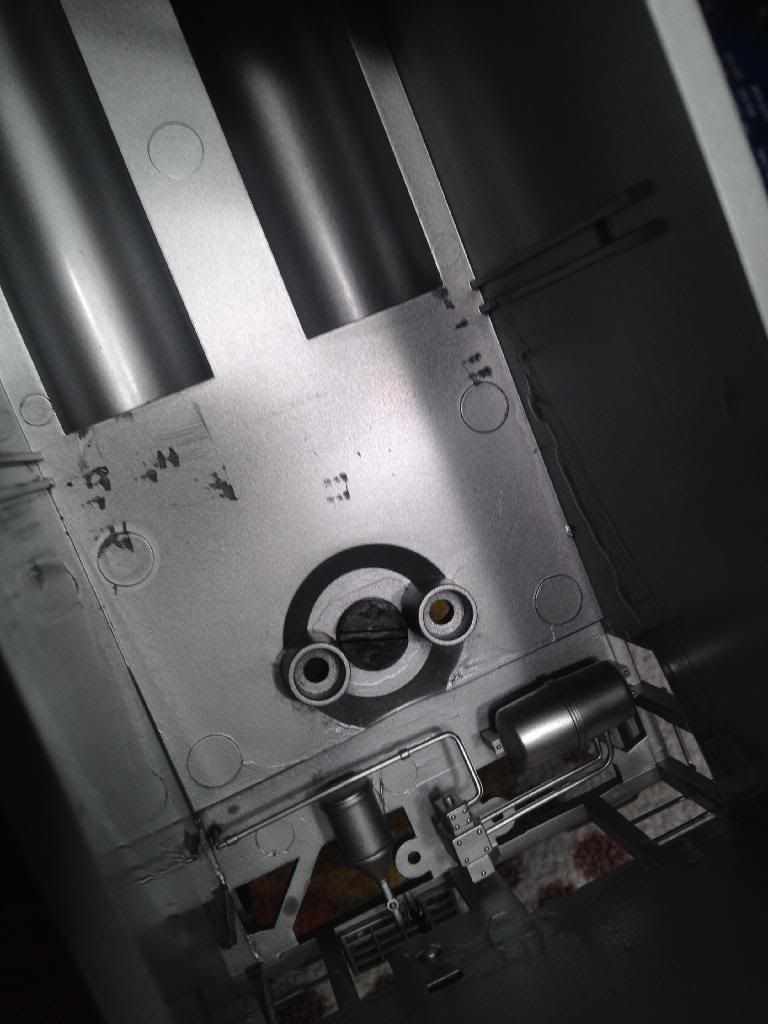

After you remove the two screws you are not out of the woods. The slopes are a very tight fit, and when MTH workers assembled the cars I imagine the paint is still tacky and therefore they are kind of fused or stuck in there. After almost breaking one end trying to pry out even after the screws removed (hence all the scuff marks) I came up with a better plan. I put some oil in a precision applicator and ran it along the seems and let it penetrate for a minute. Afterwards I flipped the car upside down and pressed the ends out with a wooden dowel. They come out much easier this way, and also go back in easy with the oil. I wiped the oil off once I was finished.

I installed Atlas 100t trucks with the adapter and there is no play at all, you really have to push the adapter in between the screw posts pretty good, when you run the screw from the bottom it pulls it all the way down for a very snug fit:

I don't know if you can lower the car anymore than this, the 100t wheels are already extremely close to rubbing the bottom of the car:

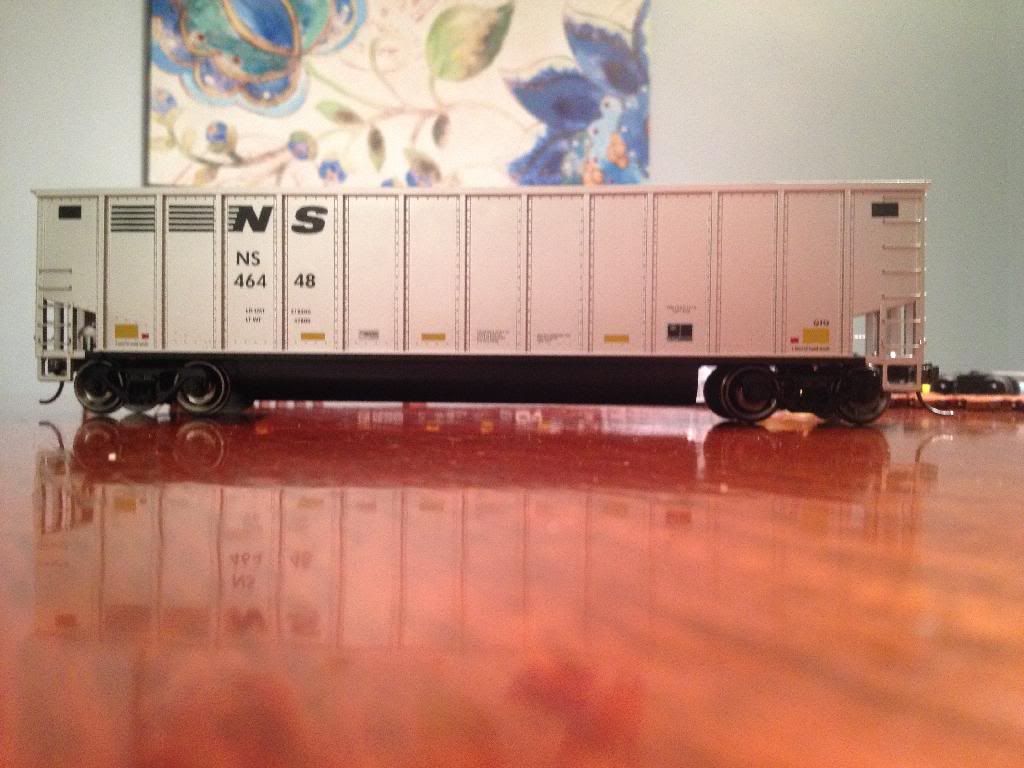

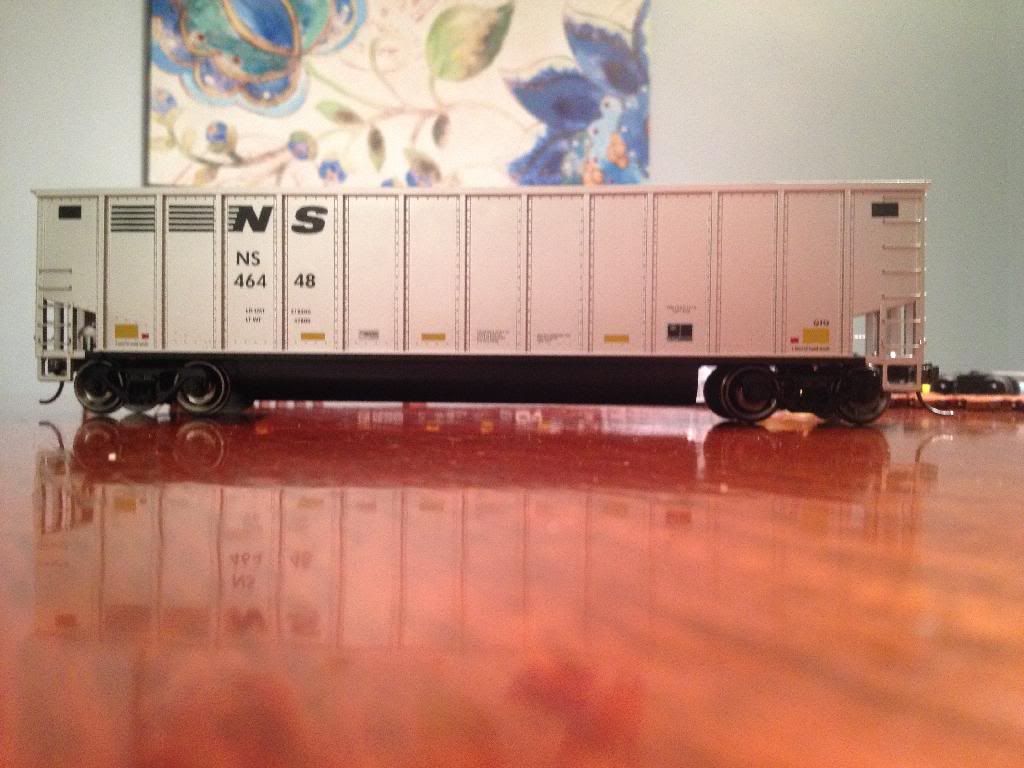

Finish product:

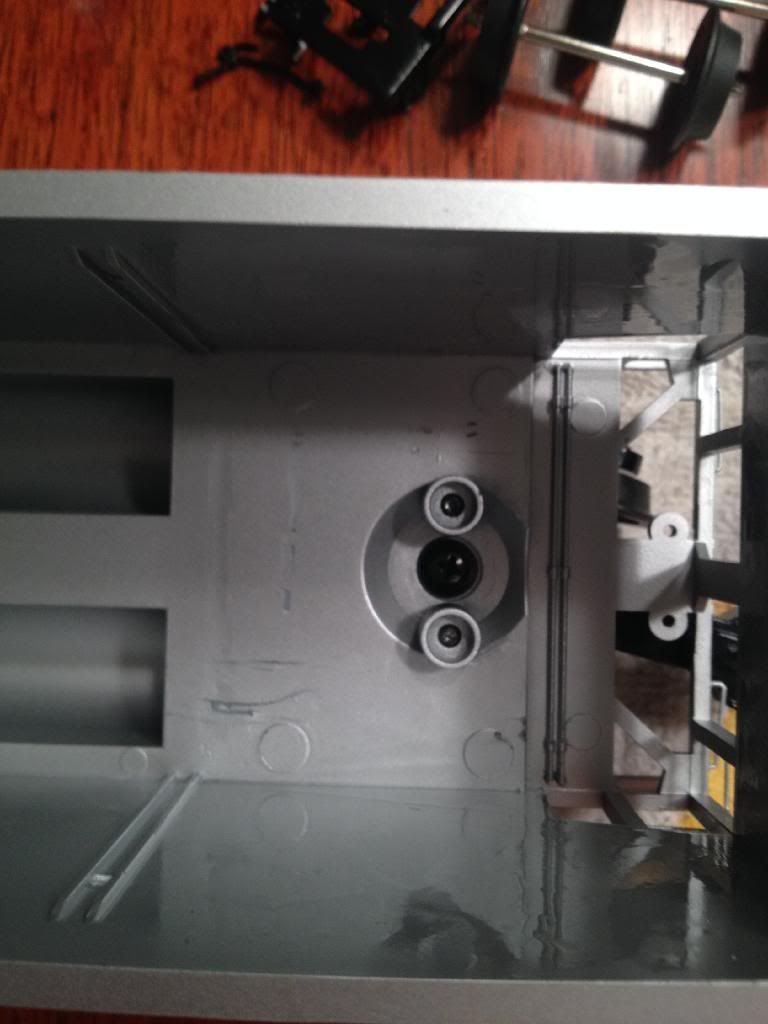

I hit the inside of the car with some silver paint and the scruffs went away...

Anyways, a Homer Simpson moment...DOH! Thanks for the help...