1.The terminal block is the most under appreciated piece of equipment manufactured by MTH.

2. The TIU/AIU should have been manufactured with 4 screw holes, to anchor them in place on the shelf where they sit.

3. When starting to wire your platform, buy the best wire stripper you can find.

4. Spade wire terminals must have a minimum 5.5 mm gap to use on the TIU.

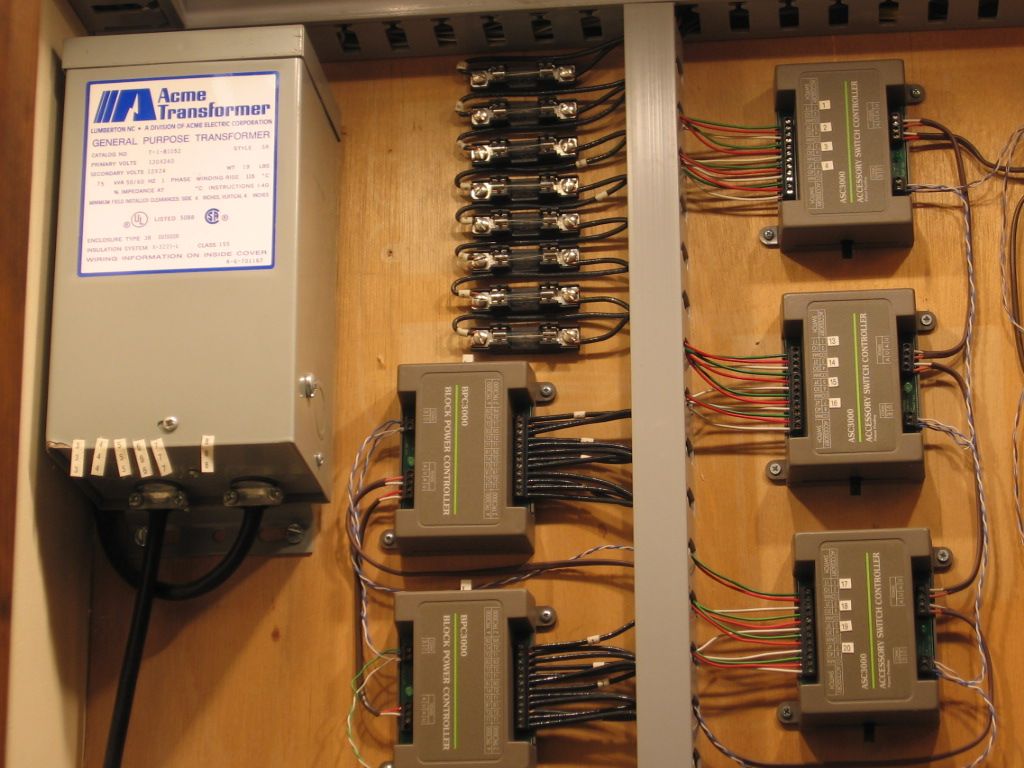

5. Add 1" ten amp quick blow fuses between the transformer and the TIUou will never have to change the 20 amp fuse in the TIU.

6. Hammer a nail next to 10 amp fuse holder. Use a small bag to store the replacement fuses. You will never have to search for fuses again.

7. When starting up your trains identify something that tells you power is going to the tracks. Mine is a Z Stuff semaphore activating on the outer track. The other is a semaphore lamp on the inner track. Caboose lights are another verification.

8. Consider to only wire switches that cannot be easily reached by hand. Otherwise use a manual throw. This can minimize excessive wiring under the platform. Don't forget to label the switch mechanisms.

9. Color code and identify all wires. My color code is red. Yours should be multicolor!

10. Rule 17 compliant locomotive headlights is a rule made to be broken. Am I the only one whose eyes are bothered by their brightness?

11. All locomotives with cab to tender deck plates needed to be manufactured an extended 2-3 mm to ensure they stay raised. Mine all fall down after 3 or fewer times around the loop. A small piece of the sticky area of a Post-It note added to the tender may resolve this problem.

12. Spare draw bars should be sold in packets of 3, all same size. I have never lengthened the draw bar, only kept them the same size or shorter.

13. Replacement traction tire size for an engine should have been listed in it's instruction manual. Same for LED types.

14. Wipe the dirt and grease off tracks 2-3 times per year.

15. Make a list of all switch and accessory names and sequence. You will have to enter them again at some point, likely more than once.

16. Moving a connected A-B-A diesel consist from a storage shelf to a operational track requires 3, maybe 4 hands.

17. Old style power connectors between locomotive and tender never came undone. The same is not true for the current circuit board style of connector, thought they do look better.

18. An eighteen volt setting from a ZW transformer may be other than that amount. Check with a volt meter and adjust as necessary.

19. Five of my 25 engines arrived with quality issues. Some were minor, others major. All were corrected to my satisfaction.

20. Is there anything worse than Christmas scented smoke fluid? Coal scent adds something.

21. WI-fi installs should identify the operating system requirements for purchasing and downloading the App from the I Tunes store.

22. A string of white miniature Christmas lights is extremely useful for illumination when working under the platform. It provides a soft illumination that is easily moved.

23. 18 gauge solid core wire is perfect for wiring the track. Solid core makes connections easier.

24. Purchase a 4 pack of interlocking 2' by 2' squares of foam pads for where you work underneath the platform. This makes it much easier on the knees.

25. When I got my first MTH engine it was a Proto Sound 1 0-8-0 NYC steamer. I was amazed that it did not have to move and would still have smoke coming out of the smoke stack. I still am.

Bill