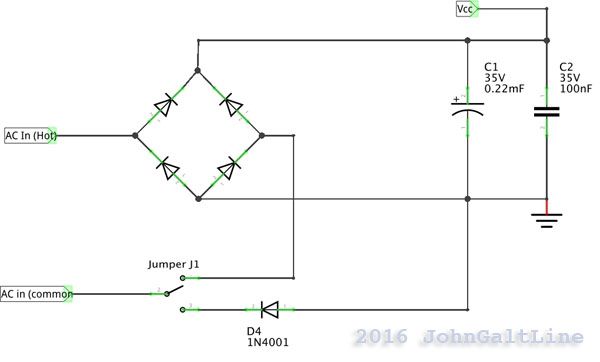

... If I use a full-wave bridge, the complete output circuit needs to be totally isolated, that doesn't work in every case.

No question this is a thorny issue. I don't think there's a simple answer.

My opinion is to go with the bridge...like the eBay LM2596 module. For rolling stock applications I think there's enough precedence with MTH in particular that guys get the concept that the chassis is NOT "ground". For track-side insulated rail triggering from outer-rail-common, I think a large % of applications can simply power the entire AC-to-DC module if that makes sense.

Separately, it's hard to tell but from the 3-D mockup I'm think that DCS inductor looks a tad small if the output current is in the 1+ Amp range? I think a lot of applications will set the output to 12V DC so the input current will be 1A (or so).

Don't get me wrong, this will be a contribution to the hobby. But I suffer from creeping feature disease and after years of trolling the OGR Electrical forum, some recurring themes might be:

- some kind of insulated-rail trigger mechanism...possibly with an opto-isolator to get around the grounding issue if you go with a bridge. Specifically there are many accessories which could benefit from DC. But some portion of the accessory is always powered, and some other portion must be triggered by, for example, an insulated rail.

- support for driving a relay. This may be the only thing the module does. The existing insulated-rail triggering modules with relays start at $10 and many don't have capacitor delays to de-chatter noisy wheels and dirty track.

- in lieu of a relay, support for driving 2 DC outputs selected by an input signal such as from an insulated-rail section. This obvious application is the red/green outputs for a signal head. The idea is one output gets DC power normally (e.g., the green LED or lamp), the other output gets DC power when the input trigger is active (e.g., the red LED or lamp). This may mean adding a transistor or two. This may mean adding 1K resistors assuming the DC module is set to 12V as 1K seems common for driving LEDs from 12V DC.

- they don't speak up, but IMO there's a silent majority of guys who simply don't want to power up the soldering iron! To that end, I think screw-terminals on the inputs and outputs would be nice. Obviously you can't just leave holes on the board to accomodate screw-terminals since that would then require soldering to put them on!

I think it worth the time to identify specific applications in rolling stock or track-side accessories that would use this and make sure the module applies with NO SOLDERING! Hard to say right now what you could sell these for but I think guys who routinely solder small components and such are NOT the target market.