Taking a break from the live steam park to play with the CNC machine. Another coaling tower, this time for an ON30 module project. Lot's more to do but a good start for today. Russ

|

|

Taking a break from the live steam park to play with the CNC machine. Another coaling tower, this time for an ON30 module project. Lot's more to do but a good start for today. Russ

Replies sorted oldest to newest

Simply beautiful!!!!!

Well done.

Looks Super Russ! How many ton coal unloading/load facility is that modeled after?

Please keep us posted on the progress

Where did you get your plans?..........Thanks Brandy!..................![]()

Impressive structures in their day. You have done a impressive rendition. Nice job!

Wow, impressive.

thank you for sharing.

Andre.

N-I-C-E! Obviously, we all need one of those CNC machines (if I even knew what it was).

Beautiful structure. Very impressive.

Very nice! ![]()

First, beautiful structure; thanks for sharing.

Second, what prototype served as the "pattern" so to speak?

are you going to make your own chute or you are going to buy them?

Andre.

Thanks for all of the nice comments, I do appreciate it. First off this is for an ON30 module set I've started working on. It is an 'artistic' representative model of the Chama New Mexico coaling tower on the narrow gauge. It is a small tower to some but for most home layouts it towers over anything else on the layout. The dimensions I got from the Sandia Software Multimedia Adventure DVD that they put out several years ago. My CNC machine is basically a large wood working computer controlled router 48x96 inch that I use for the live steam hobby stuff I do. BUT it works just fine for also doing 1/48th scale stuff! ![]() I have lots of little details that I will add over time to the tower, like the chute, weights, doors, windows, etc,. Next up is the sand house that is also at Chama. All of these structures I have already done for other layouts so it was just a matter of putting in the sintra plastic and hitting the go button! Sintra is a pvc plastic that comes in 48x96 inch sheets in various thicknesses and colors and glues up with regular old hardware store pvc pipe glue! Thanks for looking in. Russ

I have lots of little details that I will add over time to the tower, like the chute, weights, doors, windows, etc,. Next up is the sand house that is also at Chama. All of these structures I have already done for other layouts so it was just a matter of putting in the sintra plastic and hitting the go button! Sintra is a pvc plastic that comes in 48x96 inch sheets in various thicknesses and colors and glues up with regular old hardware store pvc pipe glue! Thanks for looking in. Russ

from the live steam hobby stuff I do:

cutting plywood on the CNC machine:

Russ

Beautiful job, would you cut one for me, I can add details later?

Mike P

Russ,

You are absolutely killing me with jealousy. I drooled so much over the keyboard it started to smoke.

That is one very impressive structure. What is also impressive to me is the programming effort it must have taken to program the CNC. I don't know if you did it or someone else, either way the results are amazing.

I hope you post more pictures as you progress.

Thanks,

Ed

Thanks for the information, explanation, and photos, Russ.![]()

That is a great looking addition, very well done.

" the programming effort" my machine is a commercial grade machine which means it comes with commercial grade software! ![]() The state of the art in software at this level is astounding! It took about an hour to draw and then less than 1 hour to cut. When doing a lot of structures like I do it is also possible to build up a library of already done parts, IE windows, doors etc,. Once you've done a few you also get pretty good at the 'guesstimate part'. It took 3 passes of cutting the coaling tower the first time to get everything to fit. After that it's put in the plastic and hit GO! I also have a laser cutter and a 3D printer but I seem to do lot's more 'stuff' with the cnc machine. At least lot's of bigger 'stuff'!

The state of the art in software at this level is astounding! It took about an hour to draw and then less than 1 hour to cut. When doing a lot of structures like I do it is also possible to build up a library of already done parts, IE windows, doors etc,. Once you've done a few you also get pretty good at the 'guesstimate part'. It took 3 passes of cutting the coaling tower the first time to get everything to fit. After that it's put in the plastic and hit GO! I also have a laser cutter and a 3D printer but I seem to do lot's more 'stuff' with the cnc machine. At least lot's of bigger 'stuff'! ![]() Thanks again for all the nice comments. Keeps us all motivated I think! Russ

Thanks again for all the nice comments. Keeps us all motivated I think! Russ

Great job Russ.

Alan Graziano

Wow, that is super Russ! It really helps to have the right tools, but the skill and imagination to use them well is also necessary. Clear you have all three . . .

Rus

Thanks for Sharing!! Really nice model

Really cool stuff. Nice work!![]()

Thanks for sharing.

Russ, what's the kerf size when using your CNC? One of the advantages of laser is how narrow the cut line is for making details and nice, tight, square corners.

I have a laser too and a 3d printer but the cnc is SO FAST! Actually the kerf is not to bad as I use a 1/16 inch tapered ball nose bit. On the live steam stuff I mostly a 1/8th inch ball nose for detailing and a 1/4 end mill for cutouts and also depending on the material I slow the cnc down a bit. With the sintra plastic it cuts really easily and cleanly so I can push the 'limits' a bit. I use the cnc so much for so many different kinds of projects that I'm just so comfortable using it I forget about even having the laser sometimes! ![]() I only have a 40w laser so I just do some of the trim pieces etc with it. Here is a sample of one of 'extra' curricular activities! Russ

I only have a 40w laser so I just do some of the trim pieces etc with it. Here is a sample of one of 'extra' curricular activities! Russ

Forestry Service style Fire Danger sign(s) made three of them!

Great coaling tower Russ!

Dave

Russ

Super looking. Have you ever considered cutting and kitting the basic tower as shown.

Detailing left to the buyer. Might help pay for your future products. I would buy one

Mike P

I really appreciate all the comments.

To go from a 'pile of pieces for me to assemble' to a 'kit or bag of parts for someone else to assemble' is really not as simple as it might sound. I have tried in the past on another structure (the roundhouse) and it was 'many' emails and photos and . . . to get er' done.

So the short answer is NO I'm not ready to do that again! ![]() My big deal this year is our live steam park has an International event every three years (this is the year) and sooooo my time is heavily devoted to that project. We have 2,000 folks coming bringing 350+ trains! So maybe this winter I might try making a very limited run of the towers and see how we do.

My big deal this year is our live steam park has an International event every three years (this is the year) and sooooo my time is heavily devoted to that project. We have 2,000 folks coming bringing 350+ trains! So maybe this winter I might try making a very limited run of the towers and see how we do.

Back to the kerf question, to figure edges and corners with cnc it is 1/2 of the diameter of the bit being used. So a 1/16th ballnose is a 1/32 corner cut or inside corner. So not really to noticeable. Look at the detail in the Chama Oil House doors, the man door is 3/4 inch by 1 3/4 inch for size reference. The winery style door was done with the 1/16th ballnose.

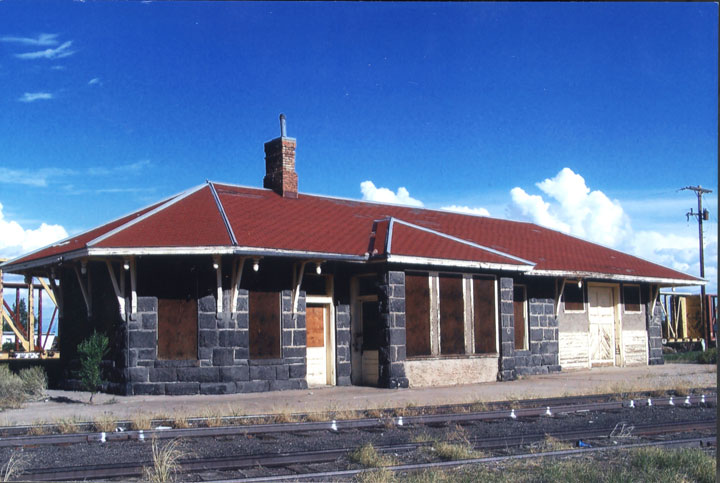

Again I do appreciate the comments. Just having fun with my toys and always looking to do some different kinds of goodies. My next really complicated cnc o scale modeling project is to do a model of the Antonito narrow gauge station. Its rough cut black basalt block construction, so trying to get that texture may be a bit of a challenge! ![]() Russ

Russ

Wow. What great modeling. It's neat to read about your equipment and strategies for various projects and see the superb results. Looking forward to your next post.

Access to this requires an OGR Forum Supporting Membership