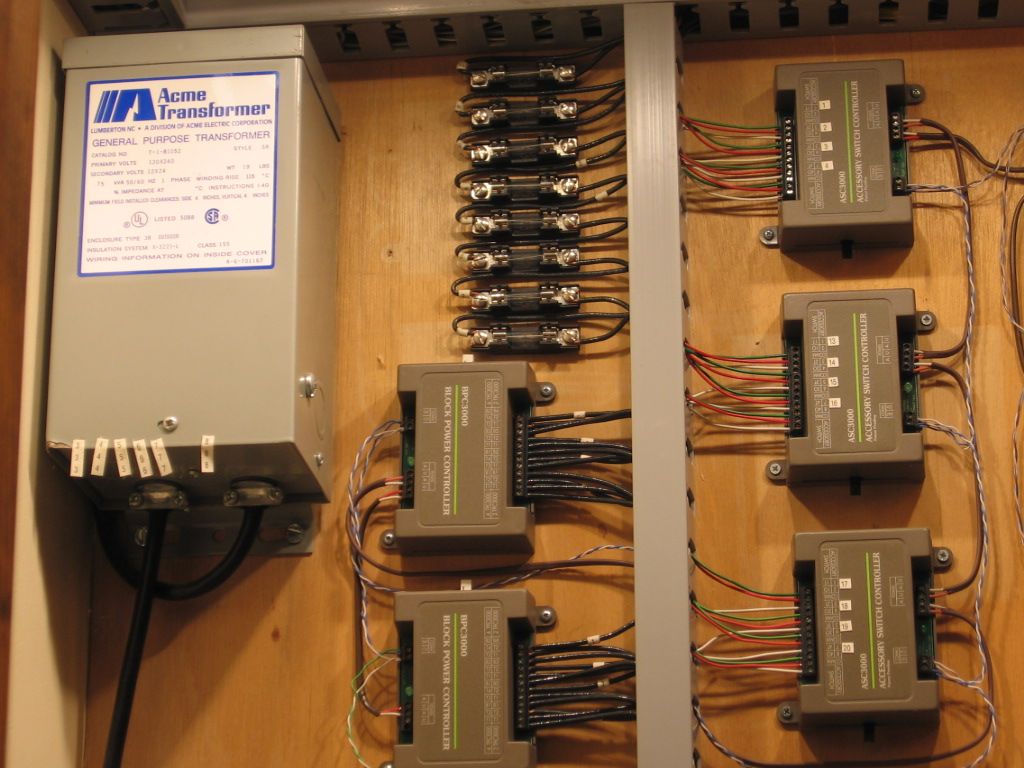

I want to thank Dennis for adding this topic since I have not wired my accessories yet, and have learned that a common voltage might not be the best approach. I want to comment on the wonderful tidy wiring that Mike had done with his Legacy control boxes, and I also have yet to do.

When I noticed the comment on the Current Transformer it induced me (pun intended) to brush up on what a Current Transformer is and how it differs from a standard voltage transformer. Of course all transformers transform both current and voltage from primary to secondary and vice versa keeping the input/output power essentially the same except for the efficiency factors. But I asked myself " What is this Current Transformer all about"

So as the this thread mentions the Current Transformer is for measuring applications. I knew The transformer itself doesn't measure, it steps currents and voltages up or down accordingly, so what was this all about.

Current transformers are transformers wired in a specific way to perform measurements, typically with an ammeter in parallel with the secondary and the primary in series with the load and the secondary across the measure device (ammeter).

It is important to keep the ammeter connected otherwise the secondary will act in its normal way and produce a very high voltage, I have pasted a more detailed explanation below.

Even though I sell ZWLs and have one, I think purchasing one just for accessories alone is expensive overkill and somewhat of a waste of the features for rail operation such as the nonlinear output voltage waveform, and the ability to program an output as an engine controlled from a remote etc .... Of course if you are using a ZWL in conjunction with track operation, as I am it is a good choice.

Current Transformer, (CT) is a type of instrument transformer used to convert a primary current into a secondary current through a magnetic medium. Its secondary winding then provides a much reduced current which can be used for detecting overcurrent, undercurrent, peak current, or average current conditions.

A current transformers primary coil is always connected in series with the main conductor giving rise to it also being referred to as a series transformer. The nominal secondary current is rated at 1A or 5A for ease of measurement. Construction can be one single primary turn as in Toroidal, Doughnut, or Bar types, or a few wound primary turns, usually for low current ratios.

Current transformers are intended to be used as proportional current devices. Therefore a current transformers secondary winding should never be operated into an open circuit, just as a voltage transformer should never be operated into a short circuit.

Very high voltages will result from open circuiting the secondary circuit of an energized current transformer so their terminals must be short-circuited if the ammeter is to be removed or when a CT is not in use before powering up the system.

Here are some of the accessories I still need to wire. Derrick in background, culvert loader/unloader not shown.

I am also trying to decide whether to use DCS or Legacy or both for accessory control.