Good Day,

|

|

Good Day,

Replies sorted oldest to newest

Look at Micro-Mark. They have a bunch and some are very affordable.

Avoid like the plague the one Harbor Freight sells since they don't carry replacement blades for that one AND IT'S THEIR OWN SAW!

Thanks Tom!

Micro-Mark sells a line of small tools that a lot of hobbyists use. I think they have a 3 or 4 inch table saw that is the right size.

Kapplar Mill and Lumber Co. has a lot of sizes that could save time and fingers.

Good Day,

Lots available - many not worth the time or cost, although that depends on what you are cutting. If you're going to be looking for precision and reliability, don't skim and go cheap.

MicroMark

Proxxon

Byrnes Model Machines --> http://www.byrnesmodelmachines.com/tablesaw.html

I rarely cut stripwood any more preferring to buy O Scale stripwood from Kappler or Mt. Albert while also retaining a full complement of fingers and thumbs attached in their original configuration, but if I was serious about going back to cutting my own stuff in other than basswood --> Byrnes.

I use a large cutting disk on a Dremel tool. It works great.

I spent some money on a fair band saw and bench disk/belt sander. Then purchased Kappler Lumber. My sweetheart does well with the band saw and sander. And I sleep well at night. My grandson at 13 has used the band saw and sander.

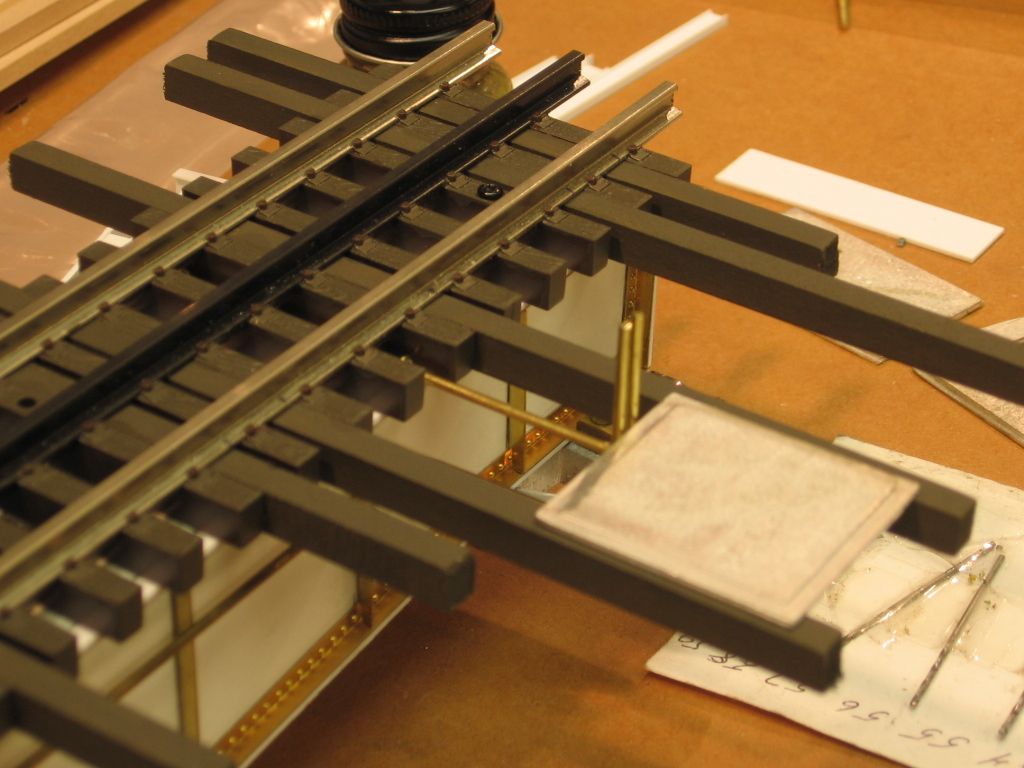

Some of the work.

Swafford,

I use these saws every single day, they are from Miro-mark and they have every single

blade and accessory available for them.

My favorite is a 18 inch Craftsman jig or scroll saw, an old one from the 1950s that uses a 1/3 hp external motor. This is the first tool I bought when we bought our first house.

My brother and I used my Dads childhood 1920s Velociped peddled powered jig saw when in the first grade or so. We made toys and later model RC boats and UC planes and even water skis and a robot. He installed a 1/4 hp motor when we were 10 or so.

It is great for model building and around the shop and will cut 2 X 4s if necessary. It is very handy to the left of my work bench.

I have others saws like the 14 inch band saw and another jig saw, a Delta 24 inch that I had to rebuild the bearing housing with MarineTex epoxy putty, but the 18 inch is just fine. I have a 15 in motorized jig saw for the grands. All my tools are bought from paper ads or garage sales.

Charlie

My first "real" electric tool was an old Dunlop scroll saw. A great wood modeling tool.

Which saw, depends on how you want to be able to cut.

The scroll saw allows some very intricate wood work, but long, smooth, straight lines aren't easy. Better have a good sander too.

The table saw is all about straight lines, and allows channel cuts, no curved cuts. It too has limits. I'd want a jig saw too.

A band saw, would be my saw of choice, if I could have no other.

Even a small porta-band in a mount, is a nice in-between, and will fit nice on a bench.

Wood, metal, whatever.

These can be taken out of the mount, and/or be used to cut solid steel many inches thick if you see fit.

These guys have two "universal" portable band saw stands(run a search on this term). One is a stand alone, and the other a vice mount.

http://www.swagoffroad.com/SWA...ccessories_c_35.html

There are lots of different types of accessory stands for these made by other mfg.s too

Portable band saws are great tools, built like rocks for industrial work.

As a home band saw, it would be tough to kill one, and the tools versatility range goes far beyond the bench.

DREMEL makes a great Table Saw!!!

Dremel discontinued their table saw years ago, and getting parts is a problem. Same thing goes for the Preac saw, as I believe the maker, Charlie Files may have passed away. A better unit than either of thes two can be seen at:

<http://www.byrnesmodelmachines.com/tablesaw.html>

They also also make a precision thickness sander for making your own strip wood.

Bill in FtL

Swafford,

I use these saws every single day, they are from Miro-mark and they have every single

blade and accessory available for them.

I'm so glad to hear that you're happy with the Micro-Mark saws, Alex as I just purchased (and received) my first one! ![]()

I always wondered if they made blades for a small Carfsman tile saw I have to cut small wood items.

I always wondered if they made blades for a small Carfsman tile saw I have to cut small wood items.

Circular saw blade mounts are near universal.

RPM, bearing, and table design, are the big factors I see in the labeling with a "type".

Smaller blades are readily had for hand held circular saws, as well as die grinders, right down to tiny Dremel saws.

I've even seen a blade on a bench grinder ![]() .

.

Some of the smaller sawblades frequently used for hobby saws are also known as "slitting" blades.

Bill in FtL

I use a large cutting disk on a Dremel tool. It works great.

Hi John,

I'm curious: what's a "large" cutting disk in Dremel-land? I have a no. 426 that's about 3.5 mm diameter that came with my recently purchased tool. How do you protect fingers and etc. vs. a more traditional saw?

Thanks,

Tomlinson Run Railroad

Good Day,

Lots available - many not worth the time or cost, although that depends on what you are cutting. If you're going to be looking for precision and reliability, don't skim and go cheap.

MicroMark

Proxxon

Byrnes Model Machines --> http://www.byrnesmodelmachines.com/tablesaw.html

...

here is the site for Proxxon...

http://www.proxxon.com/us/micr...ated-accessories.php

i think i've seen these for sale at Sears.

cheers...gary

Dremel #456 is listed as 1.5"

1.5" and larger are more commonly referred to outside Dremel inc as die grinding cutoff wheels.

A good automotive tool supply should have a 1/4" collet&1/4 shaft with blades up to about 3". That fits a Dremel.

I don't know how long those Dremel thrust bearings will last using over 1.5" though.

Traditional toothed blades can be had for die grinders too.

They have shields. But "hold tight"![]()

Exakt makes a mini plunge saw that seemed pretty cool and very safe. (no experience)

Also its the smallest plunge saw, I've seen.

Traditional saws rip flesh to shreds on contact. Disks grind it away, and normally require more pressure before they "grab" and do big injury.

I'd rather get bumped by a disc than a blade.

They burn, and injure, sure. But no automatic trauma run from a bump. Not like a toothed saw.![]()

Exploding disks do offer a different kind of danger on top of things, from debris actually embedding into you.![]()

The "diamond on steel type blades" are the only grinder disks I'd try on wood![]()

And your still liable to burn your cuts![]() .

.

Access to this requires an OGR Forum Supporting Membership