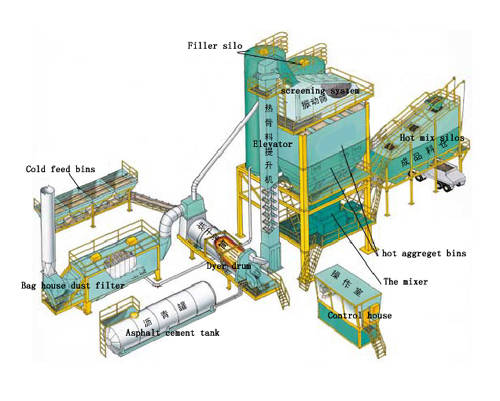

Since I could not take my car up to the car show tonight, I finished an Asphalt Batch Plant I was working on for one of my customers. Don't try to figure out the mechanics of this one because I made it all up. My customer gave me some pictures of a complete plant, but due to room limitations, I had to condense it into a 14" x 10" area.

Replies sorted oldest to newest

Alan...as usual, this model is another masterpiece! I love the green...can you share what "color" you used? It almost looks like a Sinclair green!!

Thanks,

Alan

Looks good Alan.

Thanks for sharing.

It's looking good!

Alan,

I used Rustoleum Painters Touch Meadow Green Gloss. I sprayed a matte coat over the top to cut some of the gloss and get the color a little darker. It looks fairly close to the pictures I had of this plant from my customer.

John, Lee and Alan,Thank you for your comments.

Alan Graziano

Nice "smaller" job Alan. A day does not go by that I go down to the train room, see your projects and think of you.

Al

Alan,

That looks great!

Dave

Very nice detail. When do you add the asphalt grunge to this exceptional clean plant?![]()

Don,

The customer wants this one to look new and pretty. The pictures he sent had a lot of black asphalt stains on one side of the silos.

Alan Graziano

Nice neat workmanship Mr. Graziano. You do industrial quite well. People are fortunate to have you available to craft that which they cannot. Puts some jingle in your pocket too...everyones happy...![]()

Thanks for sharing!

Bob

Alan, It looks GREAT. i LIKE THE CLEANER LOOK ALSO

great job lots of stuff in small area, i always see some really neat details in the work you do!! hope ya dont mind if i use some of them occassionally, for my own personal use of course!!

Stbbydga,

I would be happy to help you. If you want to know about any techniques I use just ask.

Bill, Flanger, Mr. Mouse, Al, Thank you for the compliments.

Alan Graziano

Upon further thought, I used to load out of a small plant in a town no one will ever think of. I recall two things. There was always a bit of hot apsalt coming down onto the hood and cab of the dump truck while loading under a silo.

The second item that will complete your plant, is a rotating pipe that is driven from the outside and has a jet engine inside one end blasting natural gas to make the paving material. If memory serves it was about... 60 feet long.

There are also a set of scales, several piles of rock (Across street was a Rail siding which conveyed rock out of hopper cars. And finally but not least, a pile of broken up concrete that was trucked back and dumped into one corner for breaking up and re-use (With the rebar recycled elsewhere)

Urve,

I would love to build the plant you have sent the plan for. I just have to find somebody with some more room on their layout to designate to this.

Alan Graziano

Alan - Another outstanding model! Thanks for sharing pictures of it with us. You are very talented and it's obvious that you love doing it.

Art

Nice, modern asphalt plants (modeled and the plans!). I opened this as I want to find

plans or an HO kit shown in a 1950-60's Model Railroader that built a small CREOSOTE plant to treat poles and ties, which I thought would be a great on line destination for a small logging operation. (I'd enlarge the HO plans and charge on) Internet search just turned up barren creosote plant sites with the EPA digging them up. (sounds like a toxic working environment) The overview in the '50's ad doesn't give any detail, but it looks like tracks go back into manmade tunnels that spray loaded, dedicated flat cars, remotely like a brick kiln operation (with dedicated cars).

Ed,

I use ABS plastic tubing. I buy it from Plastruct. It is much more expensive than PVC pipe that you could buy in a hardware store. The PVC from a hardware store has many scratches in it. You will see this when you paint, unless you do a lot of sanding. ABS tubing is very smooth. ABS sheet in thicknesses of .010-.080 can be purchased from Plasttruct and glued directly to the tubing. If you use ABS with the PVC piping you will have to glue it with CA type glue. Hope this helps. Alan

Ed,

Thank you,

The tops of the silos in this model are .020" ABS sheets cut to the diameter of the silo.

The silos are 2 inches in diameter. I actually cut the ABS sheet to 1-7/8" diameter, so it was easy to glue to the top. The silo roof is flat and I added an I-Beam stiffener accross the top. When I build tanks that have cone shaped roofs, I use .010" ABS sheets. I cut a circle the same diameter as the shell and cut a piece of pie out of it to give it the cone shape. I use a small internal strip as a backing bar to glue the cone together. That was done on the 3-inch diameter asphalt tank in the back of the model. On this tank, I simulated an insulated shell with a corrugated jacket. I glued a piece of -020" styrene that has a v-groove pattern. this was purchased from Evergreen.

Alan Graziano

Alan,

You are the master at putting together tanks, steps, pipes and walkways. I'm in awe of your work and appreciate your willingness to share your techniques. Please keep sharing your work here!