Hi

I used a motor with built in 100:1 gearbox

MFA - 918D1001 SHROUD - MOTOR GEARBOX WITH SHROUD-100:1

|

|

Hi

I used a motor with built in 100:1 gearbox

MFA - 918D1001 SHROUD - MOTOR GEARBOX WITH SHROUD-100:1

Larry Sr. posted:LocoZNB

Here are a few pictures to give you an idea of how I cut the straight track. It also shows the small shim under the track for a very good fit (ice cream stick). It can be hid with ground cover of any method you want. I did use a band saw to cut the track, then file the ends smooth. I started with cutting the track end off straight, then the notch so it would fit flush with the turntable. The Atlas 6910 is by far not the high end but it has worked very well for me. It was a pain getting the first one completed for a pattern. Then the rest were easy to make. Hope it gives you some help.

Larry

PS Note the black ties for measurements to cut.

After reading the responses about the track which can be used on the Atlas Turntable and Fastrack, I think to convert your Fastrack is easiest by just purchasing the Lionel transition piece (6-12040). From what I read it should work without any shims since now it is a piece of "O" Gauge track. Has anyone used this. I am still in the design phase of installing my turntable, but want to have everything lined up and ready.

masoner posted:Hi

I used a motor with built in 100:1 gearbox

MFA - 918D1001 SHROUD - MOTOR GEARBOX WITH SHROUD-100:1

Dear Masoner:

I am thinking of purchasing/adding this motor to my Atlas 6910 turntable. I see it comes from United Kingdom. Is that where you purchased yours? If so, do I have to do any electrical conversions, or can I just request it to be used in the U.S., so it comes ready to go? Perhaps available in the states? I am seeking a good reliable motor that is quiet. Thanks in advance.

Brian

Mine works great, although I have made a great improvement to it. I ditched the belt drive and motor and put a low RPM motor and direct gear drive on it...works fantastic. I control it using an old HO transformer I had laying around. I also use fastrack with it. I actually posted detailed pics on this forum showing how I mounted the motor, then covered it with a building. As for cutting the fastrack, there is an excellent video on youtube showing exactly how to cut the fastrack to fit the Atlas turntable.

The motor you require is

This is a 12V DC motor and will work with the Atlas reversing switch and rectifier straight from your AC track power (do not connect it directly to your track)

You can get one from these people

http://cpc.farnell.com/mfa/918...-12-24vdc/dp/MC02246

Let me know if you need more help with this

Cheers

Ted, your solution looked great, and I wanted something from over here so I bought the following on Ebay, here in the states. It too operates using the Atlas switch (cw & ccw rotation).

DC 12V Motor Micro Full Metal Speed Reduction Gear Motor 92RPM with Pull Wheel

Cost was less than $5 USD, delivered as best I can remember. It, BTW, would attach to the cover itself via (2) screws into the End Cap the drive shaft passes through.

I felt the 92RPM speed wasn't any problem.

I haven't had any time to search out a "plastic" drive pinion as I didn't want to drill out the drive pinion on the manual-handle-drive gear.

Any idea where I can find something? It should be "plastic", 16 teeth, 14.2mm Dia., the height I will have to check.

Any idea for sources or????

Norm

Thanks for all the input!!! I will consider once I get the turn table installed.

For those of you that have a Atlas 6910 turn table, does it remain locked when you use the crank? I placed mine on the table, and before I hook up the motor I tried turning it with the crank. It moved with the crank a little and then stopped. Is there a release of some sort. I do not want to force it. Any idea's here? Thanks.

Does the handle TURN and the table NOT TURN?

The handle should always turn, no stoppage at any point, even when you have the (entrance/exit) track lined up with the turntable track !

There is a period where the table does NOT revolve for a few revolutions of the handle when lined up with the track. this allows the operator to slide the (motor) drive switch to the OFF position when using the motor to drive the table.

Otherwise, you might want to remove the cover over the drive gearing and see if there is anything jammed.

Norm

Thanks Norm. I thought something was up. I will remove the cover over the drive gearing to see if there is anything jammed. I'm glad I haven't tried the motor yet.

No problem here with loco weight. Indexes perfect every time.

Norm,

Any pictures of how you installed the direct drive motor?

Joe

Hi

I am out and about right now but when I get home I will post the original instructions that I put together after I made the modifications.

regards

Joe & Ted, I haven't actually installed the motor yet. I have noted your installation Ted, looks great, but however my installation would be different at the motor is secured by (2) screws in the end cap where the drive shaft extends. The motor would mount where the manual handle mounts.

The only thing I need is a "PLASTIC" pinion to mount on the new motor shaft that would drive the gear.....the gear that is driven by the pinion that the (manual) handle presently uses (mounts on the bottom of the handle) to turn the table manually.

I don't want to use that pinion and want to keep it unchanged so I could still use the manual-handle to turn the table, should my new motor not do the job.

I haven't been able to find a pinion that I can use yet..... thus asking if anybody knows where I can find one.

Norm

Hi Norm

The only thing that I can think of is to take the pinion to a model shop and see if they can source one for you or maybe a member who is a modeler could make or modify one for you, I am in the UK so sadly I cant help.

Just for the record and for anyone else who is interested here are the original instructions from 2011

http://www.jcstudiosinc.com/At...ect-Drive-Conversion

Regards

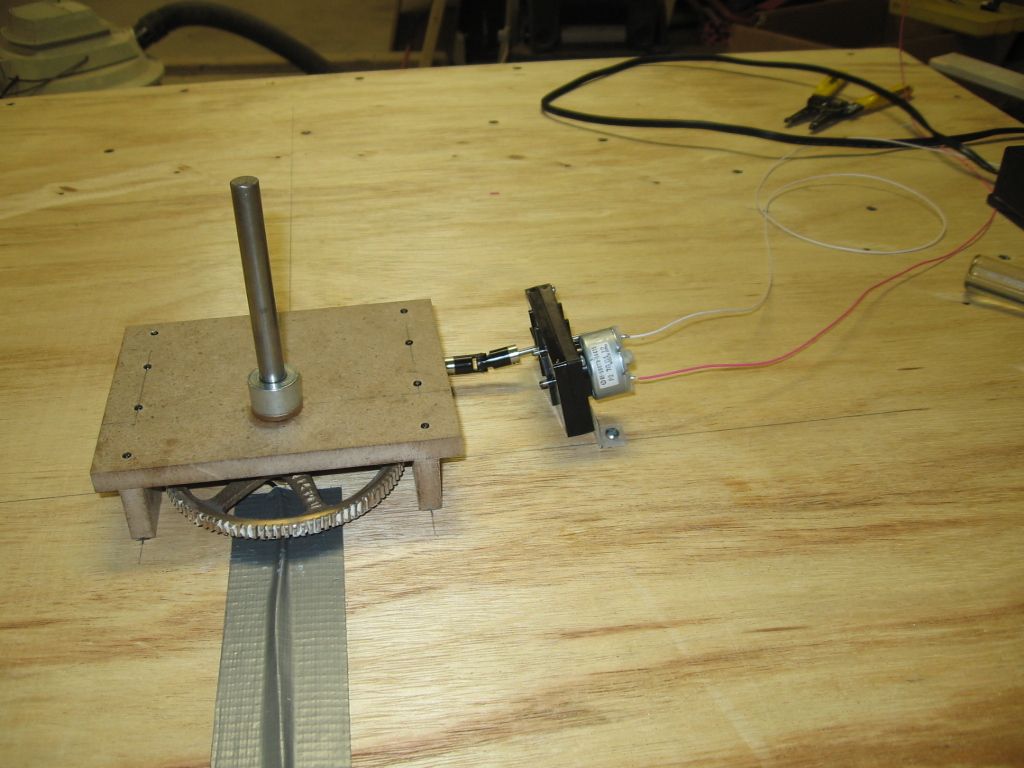

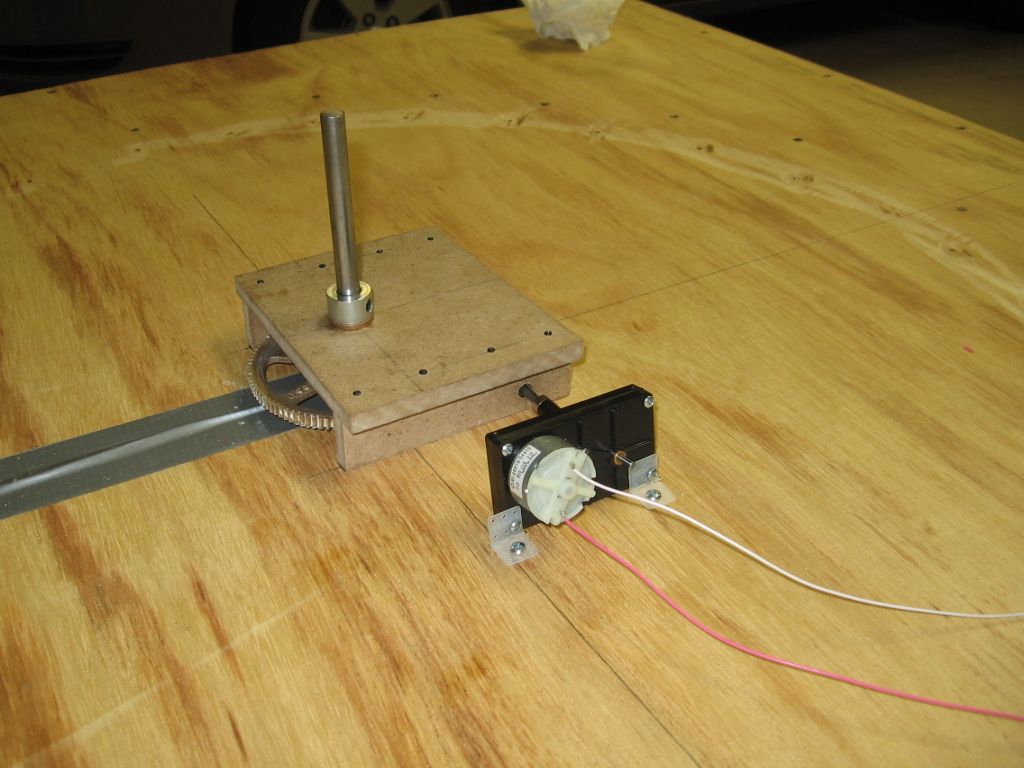

Drive system for a Diamond Scale TT, involved a gear reduction box and small 12 volt motor. It was coupled to the drive shaft with a small universal joint. Coupled an 1/8" shaft to a 3/16" shaft.

Drive box.

Universal joint/couplers are listed at the bottom of this page. Diamond Scale/if they are still in business.

This thread has some good information on how to re-motor the turntable.

joe

Access to this requires an OGR Forum Supporting Membership