The most basic two questions -

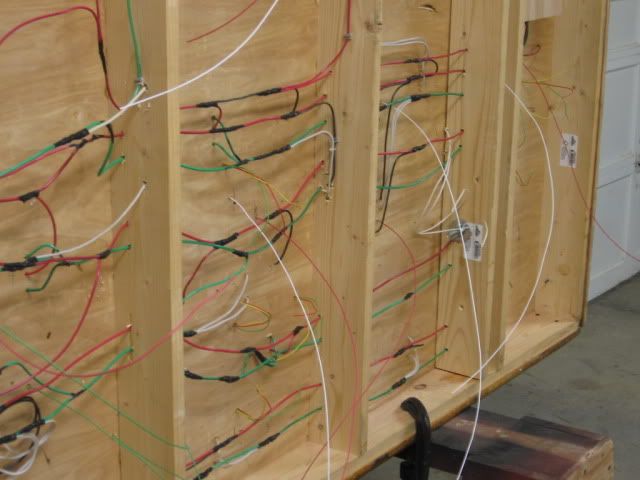

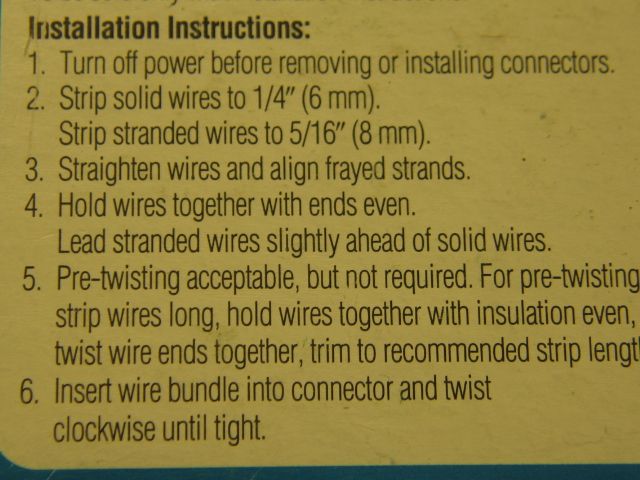

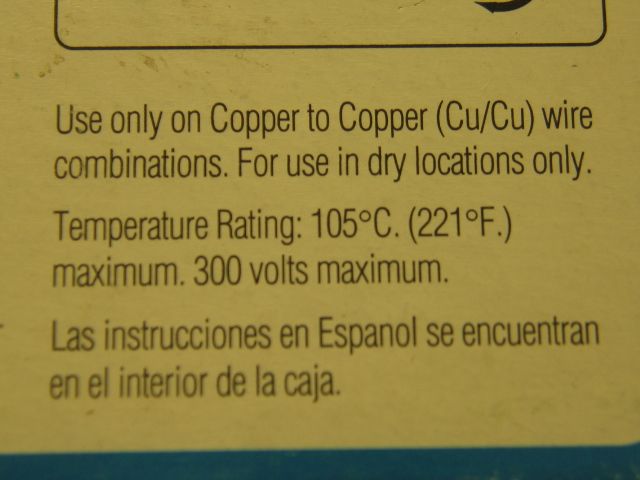

- Looking to connect the wiring from lights and other layout accessories to the buss wires I plan to run under the layout. What methods are most preferred? I wired my rails for DCS via star pattern and every power drop runs back to the terminal block, so I never had to consider a good way to connect wires under the table to a buss. And the two books I have on wiring don't specifically discuss best methods. Presumably, soldering is best, or those little suitcases. But I can't solder upside down.

- Can buss wires be like a point to point? Meaning, they start at the power source and terminate at the farthest accessory? Or do they need to form a loop that starts and then ends at the power source?

thanks!