Hello all,

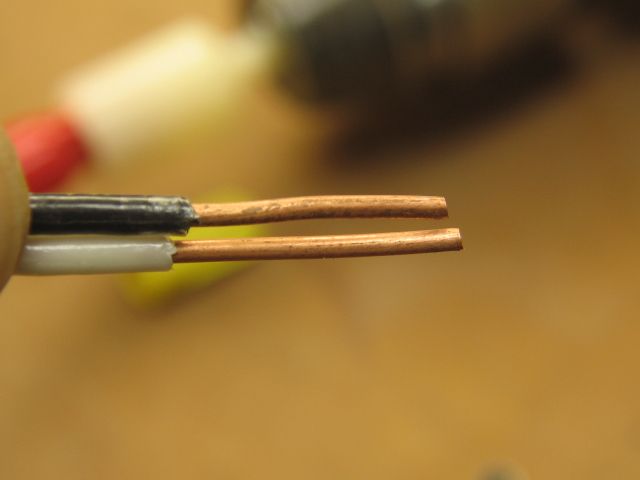

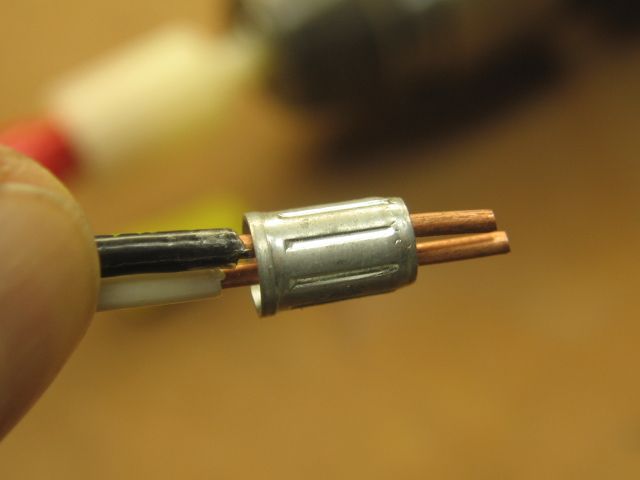

I’m starting construction of a new ~1,000 ft2 Fine Scale On30 layout using NCE DCC, ME flex track, ME turnouts/Tortoise machines, and 14 Ga. Buss with 22 Ga. drops. On my previous, similarly sized TMCC/Legacy controlled O gauge hi-rail layout I used 14 Ga. buss/wire drops with wire nuts. I had zero problems with electrical connections or command control issues.

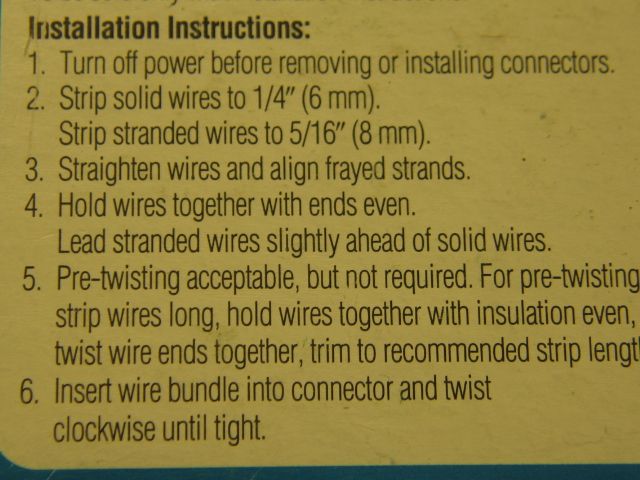

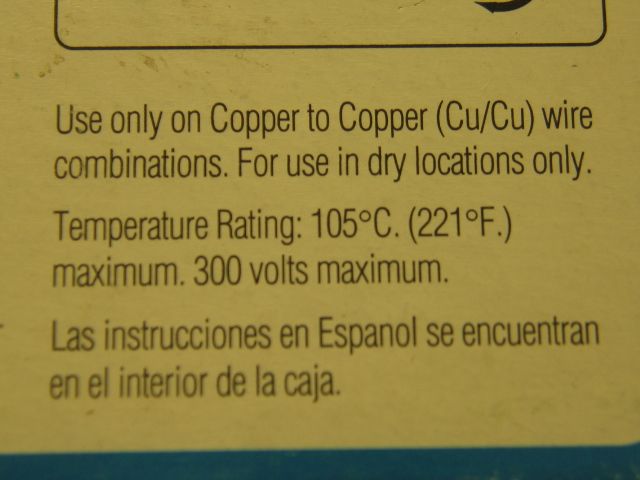

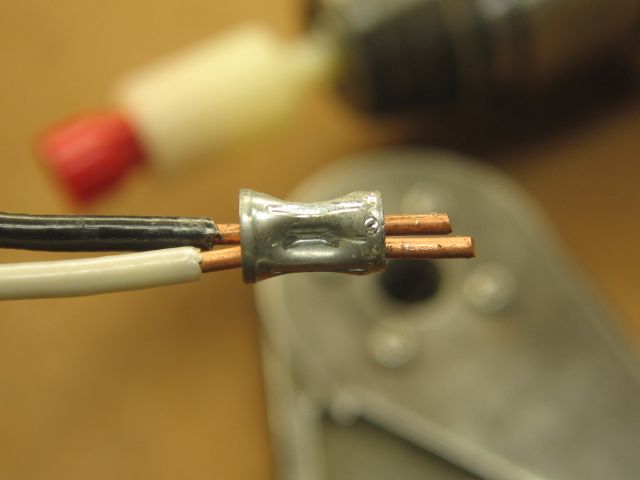

My question is: can I use wire nuts on the new DCC On30 layout? (I really like the flexibility of using wire nuts. Also, I saved a lot sections of 14 Ga wire and wire nuts I’d like to reuse.) A good friend strongly recommends using suit case connectors.

Please, technical, not preference responses.

TIA,