I'm attempting to help a friend with his layout and with a problem he is having with DZ1000 switch machines. The switch points do not consistently throw every time he activates it.

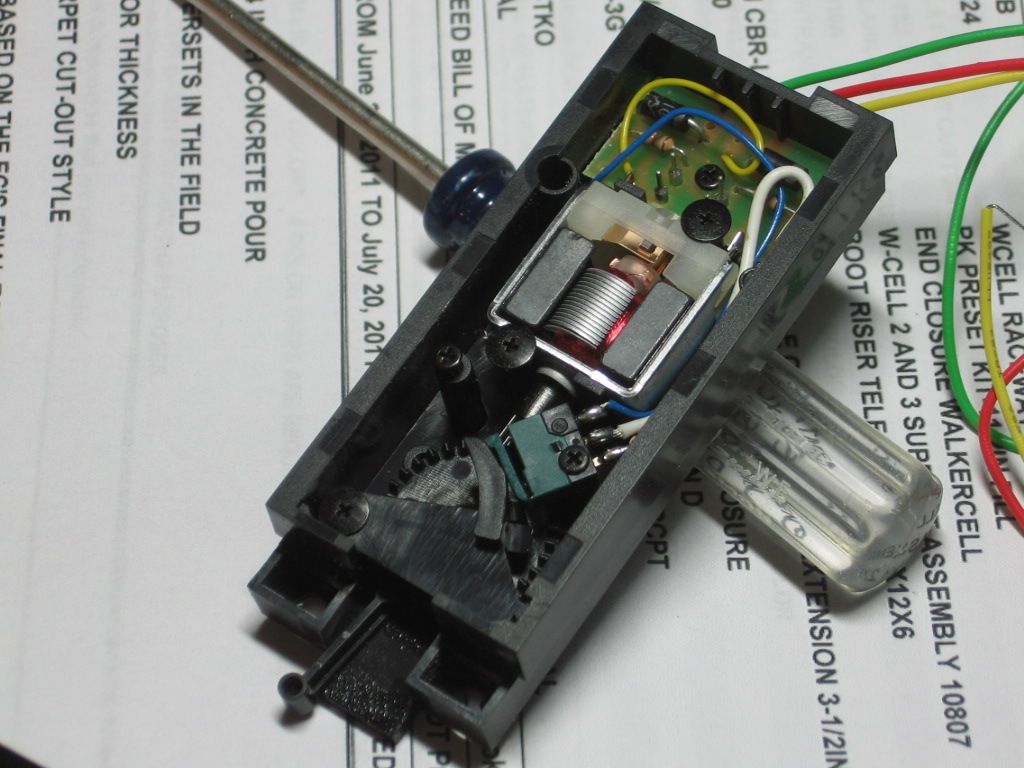

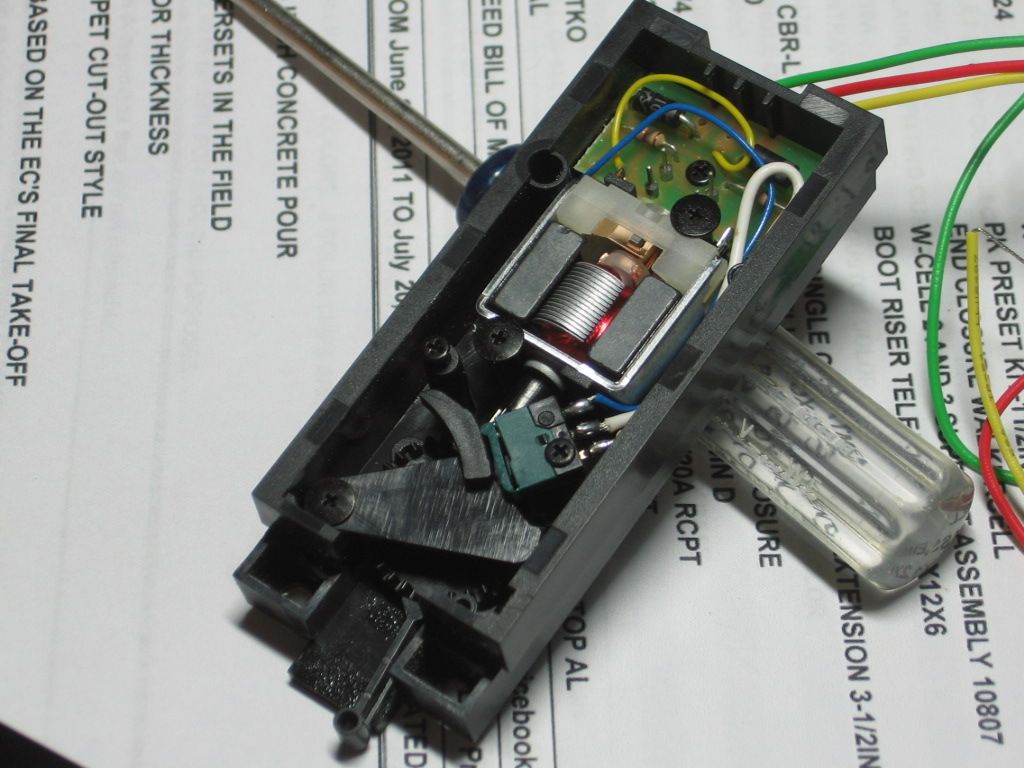

Nothing appears to be binding the switch points themselves. He opened the switch motor and watched the switch motor operate as he energized it. The problem appears to be with the tiny micro switch inside the switch motor; it appears to inhibit the switch motor from completing the throw of the switch points.

Have any of you encountered this problem and are able to shed some light on a fix?

I'm also working on getting a copy of a video he showed that clearly shows the binding inside the switch motor. I will post a response as soon as I get it.