What is the difference in Gargraves Track , Plastic or Wood ties? What is better And why?

Replies sorted oldest to newest

Gargraves track has wooden ties that can be moved on the track assembly. It has an interesting attachment to the ties that uses an addition "V" shape added to the bottom of the rail that inserts in the wooden tie.

(1.) Probably the most economical wood tie rail assembly. IMO.

(2.) Can be adapted to both Atlas and Ross track/switches with minimal work.

Air brush painted with Polyscale Railroad Tie Brown.

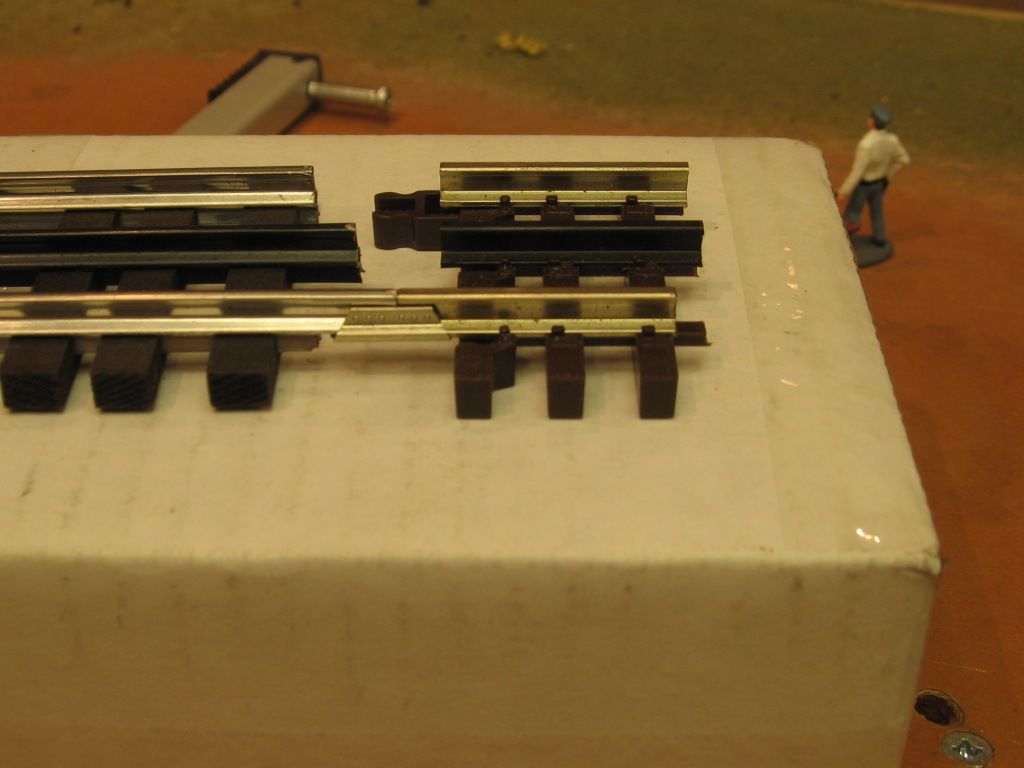

Gargraves left, Atlas track right. Atlas rail joiner.

rattler, that's correct. The GarGraves sectional curved pieces do have plastic ties.

George

Brad,

I think Gargraves fixed curve pieces may have plastic ties.

Not sure, one of the members who is certain will add a message.

John in Lansing, Ill (in one inch of snow).

Gargraves has both wood and plastic ties on the straights and the curves. I prefer the look of wood vs. plastic. I believe the plastic tie pieces are a little cheaper.

Doug

I also believe that Gargraves stainless steel rail track has plastic ties. The intent is to make it more impervious to weather for outdoor model railroads.

Paul Fischer

I have used a lot of GG track, and prefer the wood for 2 reasons: 1) It looks more realistic; and 2) it can be easily moved / adjusted if needed for things like power taps. It also seems to hold better if you screw down the track.

Jim

Wood for straights, plastic for their curves. The wood ties are moveable & desirable since their straights are now a version of flex track. The plastic ties add to rigidity on their curves.

(Now what other plausible justifications can I make up on this cold & icy morning ![]() ..)

..)

Sectional curves come in wood or plastic, just like the straights. We have a layout full of wood tie GG, sectional curves, flex track, and Ross Custom Switches. Real RR ties are wood....so why not go with wood over the plastic.

I also believe that Gargraves stainless steel rail track has plastic ties. The intent is to make it more impervious to weather for outdoor model railroads.

Paul Fischer

Stainless is available in plastic or wood.

...The wood ties are moveable & desirable since their straights are now a version of flex track...

The wood tie track has been flex track since the 1940's.

I use GG stainless with wood ties.

I like using the GG Wood ties.

I use GG stainless with wood ties.

Ditto.

For whatever reason, the SS track does not seem to get dirty as quickly. The bulk of our modular layout is Atlas. My 6' bridge section is SS Gargraves 5-rail trestle track. While we're cleaning the Atlas track at least once daily, the GG seldom needs cleaning.

As for GG wood ties, I like how they're attached to the rails.

Gilly

Brad,

Lots of wrong info above - hope you sift through the corrections.

All GG flex track has wood ties, and sectional curves/rigid straights are available in either wood or plastic tie versions.

Check the GarGraves website for everything they offer.

I prefer wood ties because I use washes of acrylic paint to weather ties and wood takes the color better, and has the texture of wood.

Jim

Sectional curves come in wood or plastic, just like the straights. We have a layout full of wood tie GG, sectional curves, flex track, and Ross Custom Switches. Real RR ties are wood....so why not go with wood over the plastic.

I've seen the flex with plastic ties, but for the most part I prefer the look of wood ties for Gargraves.

BTW, BNSF actually did look at using plastic ties (HDPE) but pretty much rejected the idea because they'd have to change over to a different fastener system to keep the rails in place (plastic doesn't spike too well.) Makes sense since a derailed car cuts a wood or HDPE tie, but often breaks a concrete one. They did briefly consider using the material in trestle repairs as everything there is bolted together. I'm digging through my files to find that report as it was an interesting read.

Just my opinion but I think the wood ties look very good...and much better than the plastic ties.

Going with wood ties on your Gargraves track will also mesh/blend in better when combined with Ross track and/or switches.

I have both the wood and plastic ties on my layout, and much prefer the wood for its looks - random subtle color variations, just like real.

Topic re-opened per request from member "ACE"...

Alan

Between A&B posted:Wood for straights, plastic for their curves. The wood ties are moveable & desirable since their straights are now a version of flex track. The plastic ties add to rigidity on their curves.

I gather that wood ties are generally preferred for appearance. The only advantage I see cited for plastic is that they hold a pre-formed radius better.

I'm wondering if wood ties have any deformation issues in damp climates, or when loose ballast is fixed with water-diluted white glue. Also, wood ties might split when nailed down or pulled up. Plastic ties might be more durable for salvage and re-use?

I have both wood and plastic ties. I drill a 1/8" hole in the tie for the screws/nails. On the wood ties the glue used to fix the ballast soaks into the wood but on the plastic the glue seats on top of the plastic tie and needs to be removed before it dries. My curved track is all plastic ties. I add black, gray or brown to the 50% glue mix in places to color the ballast. I use 100% glue along each end for the track ties before I spread the ballast and let the glue dry overnight and then add the 50% glue mix to the top of the ballast. I use a 1-1/2' paint brush to spread the ballast.

Attachments

I have both kinds of Gargraves track. Wood ties look better, plastic ties show dust after several months to a year. I use the 3/4 inch Gargraves screws to fasten my track to the plywood I use.

Also just bought some Ross switches for some MTH engines I have.

Lee Fritz

Also, for a given curve e.g. 072, 054, etc., the ACTUAL radius is a bit different for wood ties versus plastic ties.