The intrinsic operating and esthetic characteristic of Ross switches is excellent. Their track is also fine quality. Gargraves makes excellent track as well, are more price competitive on their switches but they not as realistic looking. Interchange between the two brands is seamless. The tie spacing on both brands may be a bit wide but IMO both look very good on a layout. BTW, Gargraves track is easily bent and the curves come out perfect providing they are bent around plywood jig.

Thanks for thinking of us

Please call or email when you get home

?? Sorry, I'm a little slow at times. What did you mean by this?

@rtr12, I have an Atlas switch that came to me broken that I need a new point for. Perhaps you can share the Atlas contact via email so I can get parts to fix it. thanks.

I don't have a lot of info, but I'll send you an email so we don't get too far off topic here.

THanks!

I believe the OP (nycboy) did, I didn't.

I heard that gargraves flex track cant flex below a 0-72 curve is that true? was anyone able to get it to at least reach a 0-36 curve?

No, it can be bent tighter than 0-72, but the tighter you bend it the more difficult it is. 0-54 should be no problem. A bending jig is very helpful for tighter curves. It will help prevent kinking, and give you a smoother curve.

After years of hearing how difficult Gargraves is to form into a curve I tried making curves for my new layout. It was so easy I figured something was wrong!!

I did some O-72 first.....very easy. Curves below O-72 are harder but still much easier than I had feared. I did some O-42 as that is the sharpest curve on my logging like.

Don't let fear of GG change your mind.

Atlas is available now!............. My Layout was 50' X 40'. I had 5 Mainlines and 52 Switches. I only had problems with a couple of Switches in the 10 Years I had my LAYOUT. Those problems that I had were all rectified in the Newer Switches. I installed my Track on Vinyl Roadbed. The Noise effects were pretty much Improved, especially compared to Gargraves, Ross and Fastrack! I can't say enough good about ATLAS Track!

Regards,

FREDSTRAINS

One problem with Atlas is if you are running post war with Magnatraction it will not work. Magnatraction will work on GarGraves. I plan on using Gargraves with Ross switches.

Gargraves tinplate.........Gargraves Stainless Steel is not magnetic......just an FYI.

I bought some GG SS cheap lately...I really like it.

But I still haven't really received a definite answer, Can you bend gargraves track all the way to a 0-36 radius curve?

As several have posted -Yes, you can bend it using a jig (or series of progressively smaller jigs) to get it down that tight but it may not be smooth.

Like someone else mentioned above, I'd use Ross or GG's sectional track to achieve a much smoother series of curves...

Gargraves Track or Ross Custom switches sells curve track in different sizes from 032 up to 0108 or larger. I would use a section of preformed track to cut down on the bending of flex track.

Ross has some switches with different curve radius's; example 042 & 054.

FYI; Ross and Gargraves use the same size track pins, also there are insulating pins that Gargraves sells for their track & Ross track.

Lee Fritz

Good discussion. I have different layouts in my home with several different track types.

You can buy as mentioned above the Gargraves in pre curved sections. But you must consider how many joints there are per track section. Depending on the radius you may have 3 or 4 sections of Atlas track compared to the longer Gargraves curved track sections.

A few custom curves are easy to bend not much work if careful.

It is really important to have as few track joints for good electrical and signal contact.

The longer your tracks sections the better.

For straights Gargraves is easier to cut then Atlas to length just buy a case of the straights.

I have had problems with the Atlas turnouts the switch machines do not stay connected well and need to be fixed or reconnected occasionally.

The Gargraves new improved turnouts actually work very well but Ross are best.

Again Gargraves and Ross have excellent stock and selection good pricing and are made in US.

Atlas over seas.

With Atlas the only negatives I have heard was some problems with their switches (that reputedly were ironed out), the cost and in recent years, availability, apparently Atlas Chinese suppliers have been problematic. Having seen Atlas, to me it is one of the most realistic track systems out there, for hi rail and scale folks I can understand the charm. The other thing I have heard is the power drop issues, and that it is due to the rail joiners they use, which can be finicky if you don't use them just right. On the other hand, if you use power drops every so many feet, not likely to be a problem. One other warning, my local LHS and other people have warned me that if you want to run the deeper flanged post war equipment, some of it may have problems through the switches and such.

Gargraves sectional curves are either 32" or 42", so that won't help the original poster. However, someone I know had an industrial area with very sharp curves and such, and used Gargraves flex and was able to get pretty sharp curves, at least 027 and maybe even narrower. Like everyone else, I recommend having a jig to do the tighter curves. If you are using this on an elevated structure, you may want to figure out beforehand how to tie the track to the structure, when you bend gargraves track to the right radius/diameter, it will spring back a certain amount, so when you bend it, you will need to secure it to the structure, unlike sectional track it likely won't hold the curve you desire.

I think the Atlas rail joiner problems have been addressed as well. The problem was with the early joiners with no dimples. If you have any of those, replace them with the newer dimpled ones and you should be fine. If you dis-assemble and re-assemble the track a lot they can also get loose and need some adjustment, just like the old tubular track pins do. They have definitely had problems with manufacturing the last few years as have many if not all of the other manufacturers.

The only remaining Atlas switch problems I am aware of is holding the switch button down too long and burning up the switch machines. This will happen with any twin coil switch machines, not just Atlas'.

From what I have read here on the OGR forum there are no switches that work with every engine or piece of rolling stock made 100% of the time and nothing is trouble free 100% of the time. Sooner or later any given piece will have a problem with a another piece somewhere, no matter who's item or switch or whatever it is.

There are just too many variables for everything to be compatible with everything else. That also applies to us as users. One person will have no problems with a given track system, and another one will have every problem you can imagine with the same track system.

Here are two Ross #100 RH and #101 LH 11deg. switches without straight track between the turnouts and it's about 30 1/2".

Attachments

Our club members that use Atlas track have had major issues with the switches.

After seeing what they had to go through in order to make them work right Ross would be my choice.

My layout was built with GG track and their old style turnouts so I can't vouch for their newer ones although they look much improved to me.

Nycboy,

Only buy new Gargraves flex track. My experience with being cheap and getting old stock was...angular.

Here are three nice curves bent with Gargraves flex track. O66, O54, and O48ish. The last was possible due to a Ross curved turnout there in the back. We did have trouble with the track keeping its curve at the ends. A kinked joint is visible in the center track. Staggering the ends of the rail may eliminate that.

Nathan

Attachments

Contrary to some above, I do not use a gig to bend my Gargraves. I bend it in place and screw it down as I go. I wrote a primer with photos if you want it. My email is in my profile.

.....

Dennis

Dennis,

just became a grandfather so my train building skills must improve. I have ran fastrack for some time now and this Christmas decided to play with the big boys. I chose the layout on the Gargraves website that has three loops and a figure eight in the middle. This is the start and it will grow from there. I sure hope this is ok to ask but everyone is so darn helpful here. I am having a hard time getting started and wanted to know if you could share some pictures and or video with me. I looked for your email and could not find it In your profile. How do I get started? If you have anything for the beginning stages I would forever be grateful. I am building jigs so I can bend the track but just do not know how to get started. I may have bit off more than i can chew on this but I refuse to give up on my Gargraves track. Thanks so much.

Scott

My PRR Panhandle Division is built with GarGraves track, Curtis track and switches, and Ross track and switches. I have had no problems with the track or switches. My early problems with the layout are directly related by roadbed and subroadbed mistakes I made.

I am helping a friend with the construction of a larger layout using Atlas O track. The Atlas track is heavier, more expensive, and generally gives a smooth running experience.

Things you need to consider are the ease of wiring the track, the use of insulated signal rails, and switch machines (and their control via TMCC, DCS or Legacy).

George

Atlas O vs. Gargraves (MHO)

Man, it seems as though this debate has been going on forever. Have used both, here's my thoughts, hope it helps you in making your decision.

Both great track in their own right. In the ongoing discussions that have occurred on this site over the years i don't recall anyone ever mentioning this but the solid rail Atlas uses just plain, makes the sound of the wheels sound better despite whatever sound deadening material is in place. The best I can describe this is that the sound given off by the wheelsets as they roll along the Atlas track is lower pitched. I assume this is a result of the higher density of the solid rail. Tinplate rail, whether it's GG, Ross or traditional Lionel, sounds well, "tinny'er". Don't know if this matters much to you but it is a plus for Atlas. Personally, it didn't matter to me and I converted back to Gargraves/Ross. Three main reasons? #1. GG is way easier to bend. The recoil in the Atlas flex track makes it very hard to work with and I highly doubt you could bend it anywhere near an O54 radius let alone O36. #2. Cutting GG track is way easier and if using a cutting disk (much quicker and exact than using a hacksaw) you'll go through a lot less disks than when cutting solid rail. #3. Price. GG is much less expensive. I also like the look of real wooden ties. Yes, they are larger than what's prototypical but they still look good and are easier to get the right weathered look. As far as looks go, the width of the rail-head on Atlas track is too wide for my liking. To me, it gives the appearance of a narrow gauge look. GG and Ross rail heads are narrower and thus, look more real. As far as switces/turnouts, Ross is hands-down the best and offer more sizes than any other manufacturer but if you mix them with Atlas you'll have to accept having ties that do not match in size with the Atlas (again, if that matters to you). However, I have not experienced any of the mechanical problems with Atlas switches such as those mentioned by other forum members. Personally, if I were to go with Atlas track again, i would also stick with their switches for compatability and looks. Not to make your decision harder but did you consider MTH Scale Track? If rail size matters to you, this track arguably offers the most realistic rail dimensions. While I've not used Scale Track in any great quantity, from past posts and photos posted on this forum, this track, with solid rails, has a real nice look to it and it supposedly bends easier than Atlas. You can see for youself by taking a look at past photos submitted by forum member, CSX AL (or check out his website http://home.earthlink.net/~csxal/) or take look at any of the Black Diamond Railway videos, man, can those guys make Scale Track look good.

Good luck to you.

I was about to commit to atlas, but availability is a major issue, especially here in the UK. I am using ace trains steam locos with heavy tinplate coaches, and wish to include an incline, which I will try to keep to 1/50. As the section atlas track is flat, I wondered if the loco would have less grip on gargraves circular profile. Does anyone have experience of both on inclines?

thanks in advance guys,

Steve

Gargraves has a flat top rail, not rounded like Fastrack.

A few quick, random thoughts:

IMHO, both can be made to look very nice and work very well. Much is personal preference.

My preference is for Gargraves straight section and Ross Curved Track Sections and Switches. I have never found Gargraves to bend nearly as easily as HO flex track....which truly flexes any way you'd like. Gargraves flex track is a battle. I lost mine.

Reading between the lines, what I'm saying is that I, personally, do NOT recommend Gargraves switches. Ross Switches are MUCH nicer....in every way.

To the OP: at some point, you'll most likely regret not installing a crossover. My Ross double crossover, which I think cost $350 or so more than 10 years ago, is VERY nice.

I also recommend black screws to secure your track. Brass and stainless really jump out at you.

For what it's worth......

I have used Gargraves Flextrack since installing five 14 x 32 tracks in 1992 and an equal amount later on a 15x23 1997 layout[both layouts now dismantled, I currently have a 9x16 small attic layout]. Similar to Dennis' method I bend and fasten the track to a marked centerline as I proceed--no pre-bending, curve templates or jigs necessary. My underlayment is split Midwest Cork.

The key to perfect kink-free joints is to leave the screws out about 8 ties back from the curve joint on both the trailing side and the leading side of the joint as you proceed forward bending and fastening the next 37" curve section. After bending to centerline mark and installing screws in the leading 37" curve section and driving the askew rails up partially, return to the trailing joint and with a block flat against the outer edge of the ties ease the joint inward til it fully aligns the center rail with the marked centerline. Hold position, drill and install screws in second tie back from the joint on each side. Drive the center and outer rails up snugly but not jamb tight. Kink free curve joint.

If your Flex has been stored and ties have dried out spray liberally and soak with WD-40 overnight. WD-40 odor will abate later.

Do not try to bend short sections of flex---for example use two 24" sections in a 48" curve run rather than a 37" section + a 11" section. [You can ease a 37/11 joint inward but it takes far too many screws in the wooden ties of the 11" to hold the joint in position--not a good risk].

After glue ballasting has cured I remove track screws, fill tie holes and paint the tie with a brown/black Sharpie.

036 is doable with flextrack. Just swing and mark an 18' radius from the pivot point of your potential curve and and proceed to bend and screw until center rail aligns with centerline mark. Use the similar procedure as noted above to ease the trailing curve joint in to centerline.

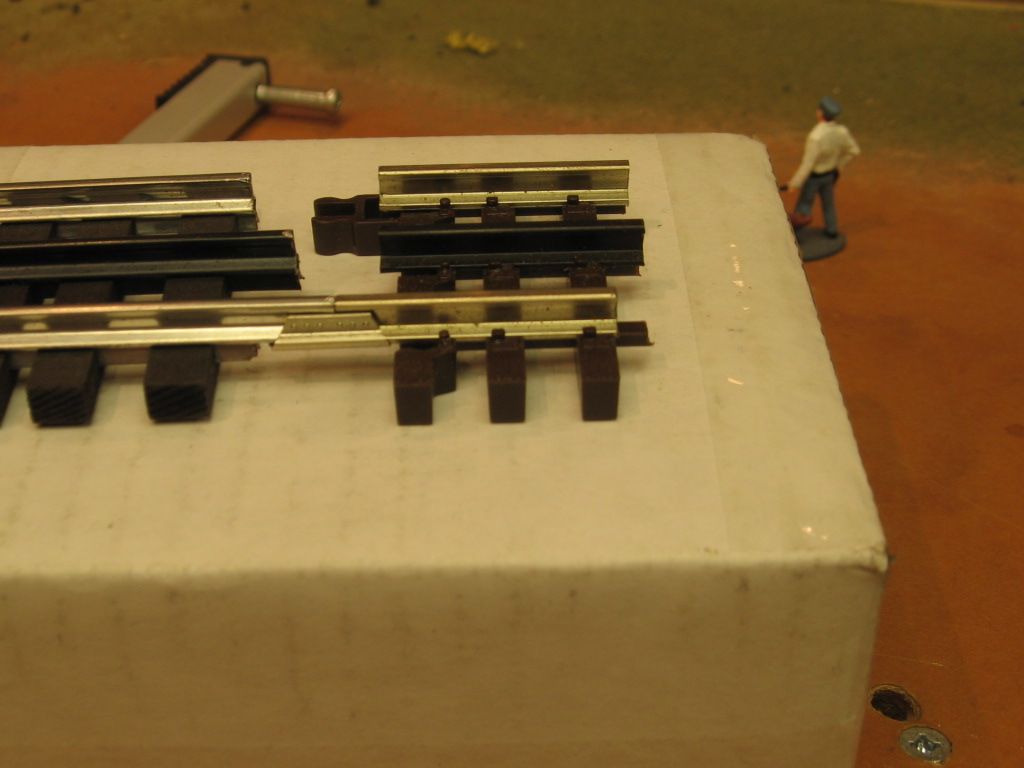

Gargraves and Atlas pictured. Connected with an Atlas rail joiner. The bottom profile of the Gargraves track has to be removed with a dremel tool. You can use a combination of different track products including Ross and Ross switches.

Good advice from Dewey. One method that I had read about was first soldering all the track that you would use in the curve together and bending it all at once. Seems it could be unwieldy. Has anyone here tried it?

Also, Atlas makes an adapter pin for GG that has half a rail joiner attached to a GG sized pin.