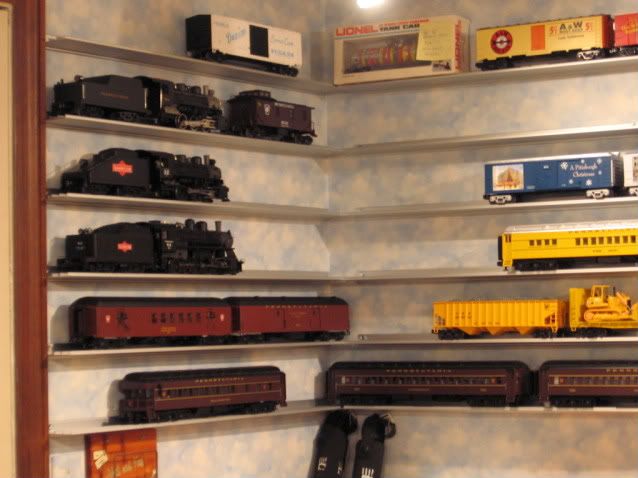

Just a quick plug for Glenn Synder train shelves. Picked a handful of these up at York (my first train shelves) and installed them today. They were easy to put up, look great, and display trains beautifully.

Highly recommended. ![]()

|

|

Just a quick plug for Glenn Synder train shelves. Picked a handful of these up at York (my first train shelves) and installed them today. They were easy to put up, look great, and display trains beautifully.

Highly recommended. ![]()

Replies sorted oldest to newest

I looked at these also and they are nice. I would have several 9' long shelves stacked up on one wall, maybe 8" between shelves. I was thinking of adding 2x4s vertically on each end to help protect the shelves from being hit as well as dress it up some. However, I didn't buy because I had a couple concerns.

1) Can one of the 6' shelves hold the weight of two large and expensive die cast steam engines? I know you are suppose to drill holes in the shelves and screw them to studs, but will the metal bend?

2) My shelves would go in a high traffic hallway. The shelves are narrow but have a slight tilt up to help prevent the engines from falling off. However, it still seems like items on it might be easily knocked off. What are your thoughts on this?

Thanks.

Ron

Installation Instructions (copied from the Glenn Snyder Display System website)

Glenn Snyder Display Systems are easy to install. You will need the following tools: An electric drill, 1/8" and 3/16" drill bits, a level, #10 x 1-1/2" round head, pan head or truss head sheet metal screws for each stud and spacing blocks. Spacing blocks should be as high as the distance between the shelves, generally between 5-1/2" or 6" for O gauge. Studs are usually located 16" or 24" apart on center. Electrical outlets are generally attached to the side of a stud, which is the easiest way to locate one, or may be found with a magnetic stud finder.

Installation Instructions: Using the level, draw a line where you would like the bottom shelf to be located. Locate the studs along this line. Mark the stud spacing and transfer the marks to the back of the shelf. Using the 3/16"drill bit, drill clearance holes in the shelf from the back, using the groove to locate the tip of the drill bit. Using the 1/8" drill bit, drill pilot holes in the studs and fasten your shelf with the #10x1-1/2" long sheet metal screws. (We use them instead of wood screws as they are threaded to the top of the screw giving them more fastening power.) Once the bottom shelf is fastened, place the spacing blocks on the top of the rails, equal distance apart. Place the next shelf on top of the blocks and mark where each fastener hole is to be drilled. Remove the shelf, drill the holes in the shelf and in the studs and attach the second shelf. Continue installing the shelving by using the spacing blocks until installation is complete.

Use of Connecting Pins: On walls where longer shelves are needed or uneven areas, use the connecting pins that are supplied. Tap ends of pins open with a center punch or similar tool. Slide one end onto a rail and gently tap it with a hammer until the pin is all the way on the rail. Take the second shelf and locate the open end of the pin on the corresponding rail. Tap the pin half way back until the two shelves meet, then fasten the shelf to the wall. If your walls are uneven, place screws through washers where needed between the shelf and the wall until the shelving remains straight when the screws are tightened

....

1) Can one of the 6' shelves hold the weight of two large and expensive die cast steam engines? I know you are suppose to drill holes in the shelves and screw them to studs, but will the metal bend?

2) My shelves would go in a high traffic hallway. The shelves are narrow but have a slight tilt up to help prevent the engines from falling off. However, it still seems like items on it might be easily knocked off. What are your thoughts on this?

i can answer your first question without hesitation. on two different 6' GS shelves i have a combination of a #1 gauge live steam locomotive along with a Lionel #400 on one and a Lionel #392 on the other. they have been up for at least 6 months now and are rock solid. i used their recommended screws and the stud spacing is a standard 16". if your wall is warped more than usual, i might up the screw size by 1/2". i have had to use spacer washers between the shelf and the wall on another stack of shelves.

i might be concerned with a high traffic area. some model pieces do extend beyond the shelf edge and i would be concerned with people in sweaters walking close-by. i'm sure before long you would see a scene of someone complaining about the snag in their garment as your locomotive plummets to the ground.

all the shelves i have put up are not in areas where people need to walk by but they are all positioned so people can walk up to them.

my only complaint with GS is that i wish they had come standard in various lengths. needing 5' shelves in one area, i now have a number of 11.8" pieces i will probably eventually use on a skinny piece of wall, but would hardly ever think about needing.

cheers...gary

I have about 20 of those shelves, fully loaded with engines and cars, and never had an issue with them. I live in CA, and yes they survived the earthquakes w/o any incidents. I have a BigBoy, a Challenger, and a Northern all on one shelf. Obviously the shelves are screwed into the wall studs and very sturdy.

I would of bought about 10 more but they wont let me take them on the plane, so I'll just order when I get home.

Ron,

It looks like you got answers up above. I would just reiterate that if you follow the installation instructions, use the recommended screws, and make sure you're anchored well in the studs, you should be fine on weight.

Good luck.

Thanks everyone for the responses. The wall the shelves are going to be attached to are 3/4" plywood with studs at 8" (its our tornado/hurricane shelter). Looks like engine weight will not be a problem.

While the hallway is not that wide, I think I can put some cabinets below the shelves that are wider than the shelves which would help keep people away from the trains.

Ron

Access to this requires an OGR Forum Supporting Membership