I will be using 1" X 4" cross-members for my new layout ranging from 36" to 48" long and would like to pre-drill holes to run wiring. It's an around-the-wall with two 12' legs and 12' across the top and two main loops and will have Legacy and DCS with distribution blocks and track blocks and lots of accessories and switches - so a fair amount of wire.

1. How many holes and/or spacing in each cross-member ?

2. What diameter holes ?

3. Spade bit or hole cutter ?

4. Would you use grommets or something else in the holes to minimize potential wear ?

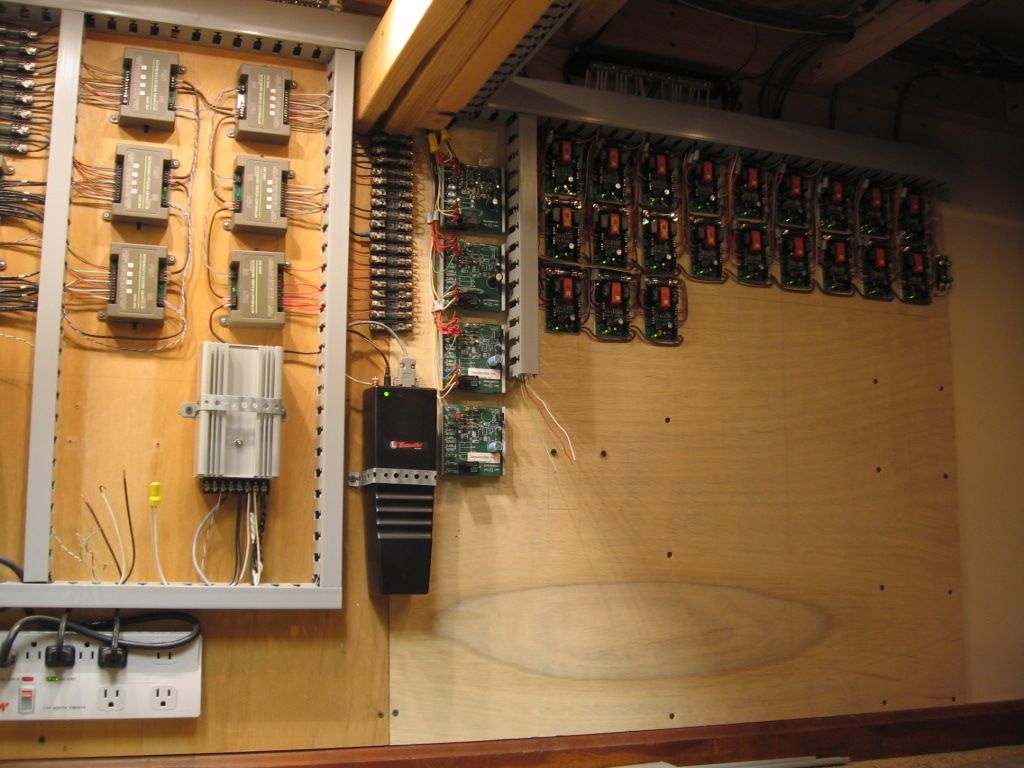

Preliminary mock-up shown.

Thanks in advance.