There are some brilliant minds on this forum. I have never figured out a way to really know how wet or dry the wadding is in my various smoke units. The result is scorched wadding and poor smoke if you don't add enough fluid, or smoke unit overflow if you add too much. I know I am not alone with this problem. Frequently, when I disassemble smoke units I am surprised at what I see. Here are some ideas: A dip stick of some sort that would respond when it touches fluid dampened wadding. Or maybe changes color like ph test strips used in swimming pools. Or maybe some kind of led with a magnifier to insert in the stack to visualize the wadding. I know some medical instruments have this kind of capability. I am open to ideas. Here would be a great product for someone. Phil

Replies sorted oldest to newest

I am not a smoke unit scientist but I know one thing,your going to have to replace burnt wadding from time to time no matter what.Nick

Interesting post Phil. I agree it is hit or miss in many cases. And I don't know whether to put half a eyedropper full on all the engines much less know how long each engine will smoke per refill.

Paul

i pretty much know how much to put in each one.

Attachments

I've developed a "rule of thumb" for smoke refills of the typical fan driven smoke units. I add about 1/3 of a JT Megasteam dropper when the smoke volume starts to fall off noticeably.

I'd like to come up with a smoke unit reservoir that would allow longer run times before refilling.

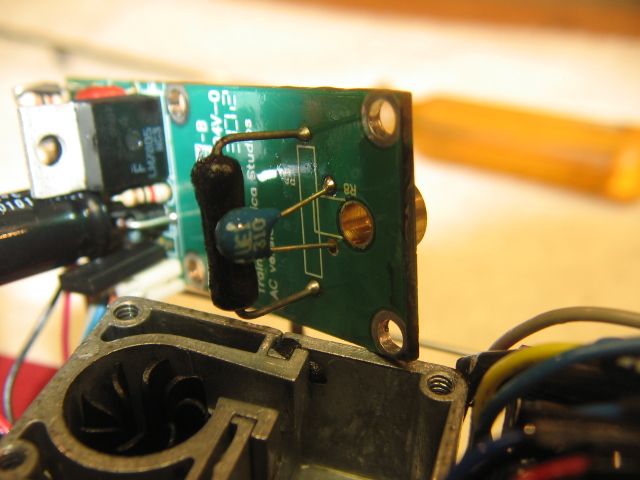

Note that TAS used to have a thermistor in some of their smoke units to shutdown when it ran out of fluid, but they still burned the wick. ![]()

Does anyone find the length of time is extended when running MTH engines in the moderate or light smoke mode?

Phil, I'm sorry for the questions on your thread.

Paul

Paul, as with everything else, it varies, depending on the specific locomotive and the condition of the smoke unit.

How about electronic measurement of fluid level with a visual display on the Legacy or DCS remote?

as long as your getting white smoke you are usually ok with fluid. when it starts to smell a little dry and turn blue is when you need to dd fluid.

How about electronic measurement of fluid level with a visual display on the Legacy or DCS remote?

How about cheap rides to the moon? ![]()

The TAS smoke units that are found in Atlas O models have a low fluid cut-out, a Thermistor, I believe. A safety feature to inhibit smoke resistor burnout.

It's the blue thing. If the thermistor cuts the power to the black smoke resistor pictured it could also trip a indication light. Low fluid. But at the same time the smoke will stop anyway.

I like the idea but it's not practicle on diesel units with dual stacks and a single smoke unit. That or it could be 3 times as long as it needs to be like on our plow trucks. ![]()

Doug

The TAS units have the thermistor, but it was more trouble than it was worth.

I would like to see a removable hatch over the smoke unit.