A little more info on these cars , they are created from resin castings.

I am no expert as some modellers ,but I used drawings of Pullman , and Greenville

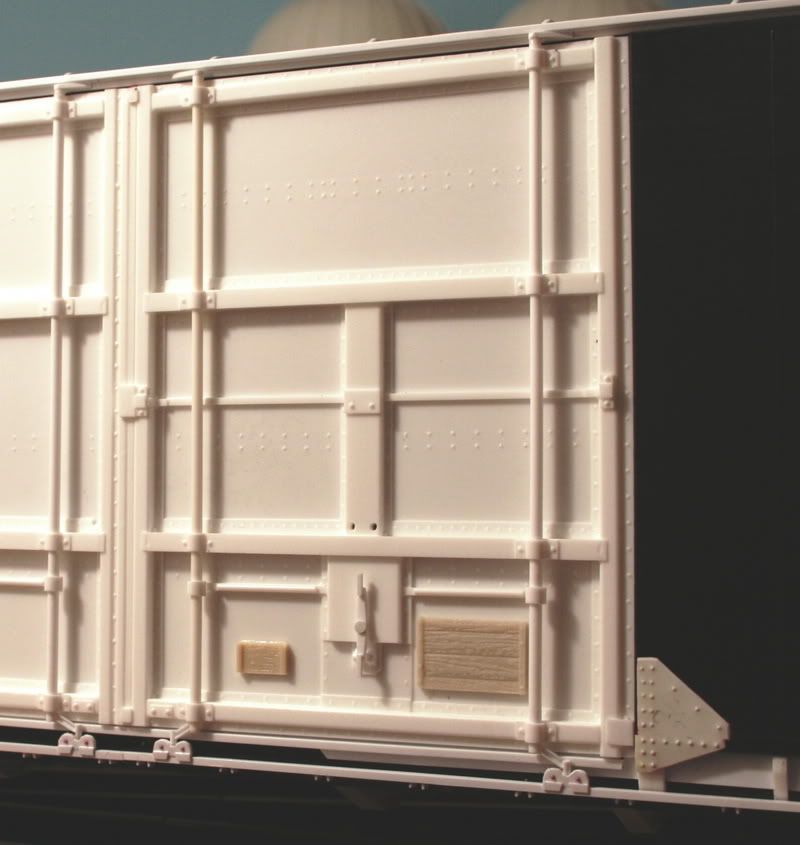

to make the molds . And from archive photos . These are constructed of 6 resin sides and then the door arms are brass as well as all the grab irons etc.

The only store bought items are trucks couplers , brake wheel and brake cyl. underneath. There are 188 seperate parts total plus the decals in an 8 door car.

It takes 45 hrs to build one and I have done 31 to date.I have an Alps Printer and Adobe Illustrator set up on a stand alone computer to create the decals.

Lukas, yes the DT&I still has some floating around , the DT&I modellers site has lots of pictures of these . My shop here in Florida is next to the CSX main line and I have 2 sidings where from time to time one of these are parked, never seen an 8 door though.

I grew up in Dearborn Mich. so back in the early 70's lots of these were everywhere. I love the giant logo's.

I am currently working on an outside braced 8 door that Southern Pacific had.

Matt, I do not have any more auto racks left , I had built 10 , and a man in Palm Beach made me an offer I could not refuse , I do have the Jigs and fixtures to make the tri-levels though . I have a couple that are partially built.

I am now into modern era , stack cars , and the nice thing about the hy-cubes is that they are still out there and some just have the old logo's painted over.

I just saw a Wabash 4 door on a siding down here.the logos were just blocked out in blue paint.

As far as the radius , I think 60" is about what you need . Atlas trucks will not work on these , they are too wide. I have one customer who provides Proto-craft trucks the new ones. I use the Weaver plastic trucks with metal wheelsets. For 3 rail ,Weaver diecast is what I use.

These look more impressive up close as the files here can only be so big. The door arms and all the add on details really make for a nice model especially the riveted panels on the sides.There were welded seam , riveted sides in various types , I have 5 different sides , 3 different ends , 3 different roofs . I am working on possibly offering these as a kit , but are not easy to build as I use super glue to bond all the sides and once the backsides of all castings are prepped (sanded) and attached , if you don't get it on perfect ,you won't get them apart. The sides are less than .080 thick.

Matt here is a picture of a ATSF autoveyor