Well, here I am again on my "other sick engine" thread.

To clear things a little. My track voltage is a constant 18 v from a DCS TIU Fixed Voltage output. So, when I say I "raised the track voltage," that was wrong! What I did was rotate the thumbwheel on the DCS remote to make the engine go faster! It is NOT being run conventionally! (Yes, I have done so in the past . . . with the same problem, but that is not how it's being tested now.) I do not have a CAB-1. My CAB-2 is broken and unlikely to be replaced. I am running the engine (trying to) as TMCC with a DCS system.

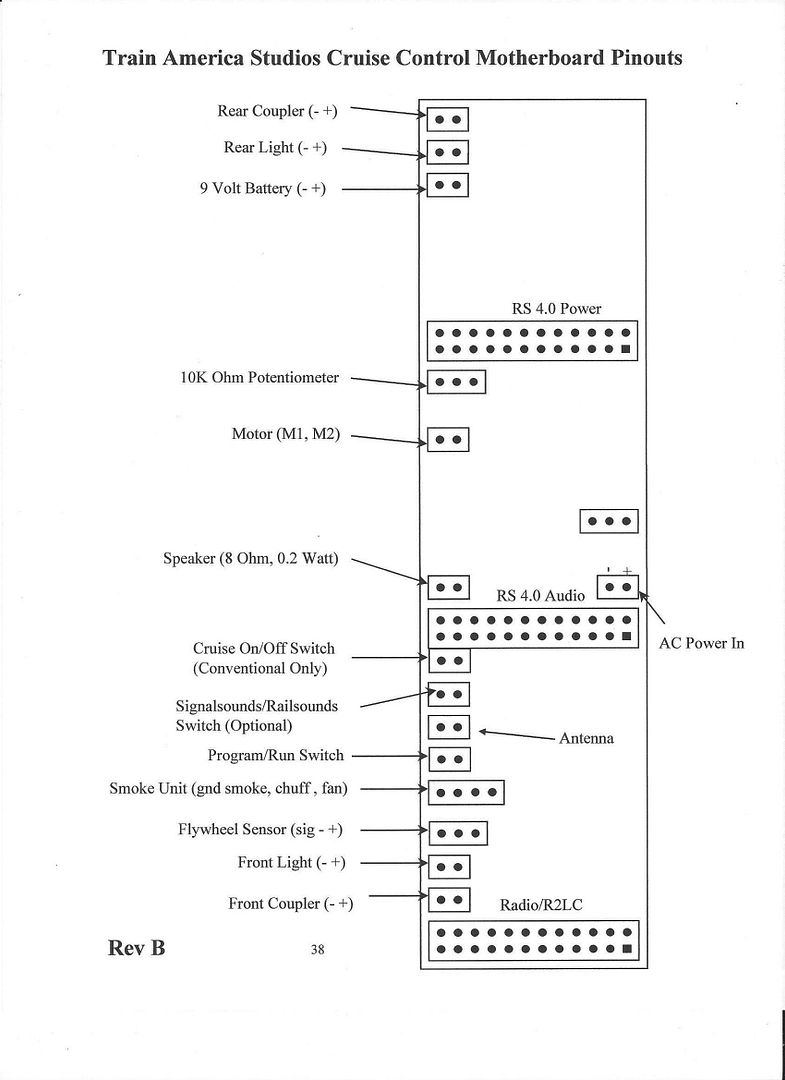

I really have abandoned the TAS board and its daughters completely. It is gutted and I have no stomach to reinstall these boards for any further testing! If they were not defective to begin with, they may well be now as I have made no attempt to ensure they were being treated at all "properly" since essentially giving up on the engine in despair last spring after it died two days after being repaired.

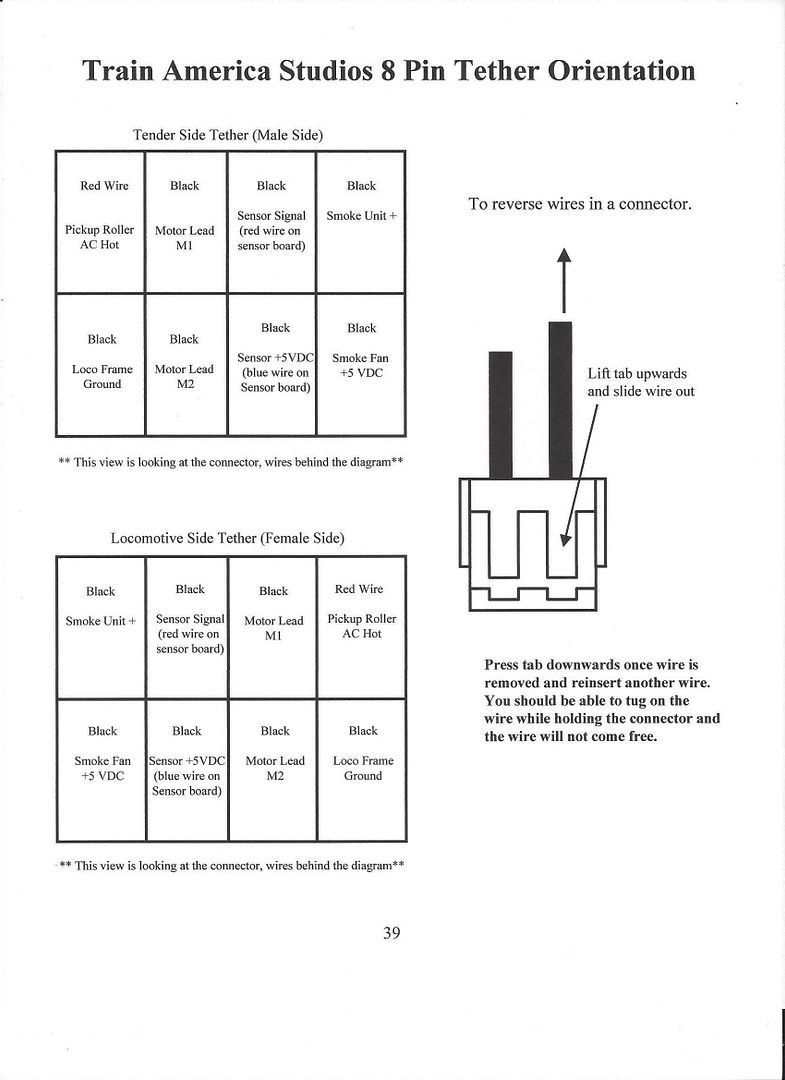

Only hope for my 2816 now is a complete, new, ERR Cruise Commander and Rail Sounds install. The tach strip on the flywheel is now irrelevant. I will use a reed switch/magnet on a tender wheel instead. So, "heck" with those three wires on the tether! I can ignore them!

Thanks to those here, I have mapped out the 9 wires in the tether from the engine.

Whether I can get these other 6 wires properly connected to the Criuse Commander board, remains to be seen.

What's the worst that can happen? An expensive (VERY!!) engine is already totally broken! I can't "break" it any further! And Weaver is out of business!

Already, problems are apparent. The antenna input to the CC board requires a single slide-on connector. These &^%$#@ nano connectors are Satan's own spawn!  So, I have to take this one baby step at a time. How does one attach an antenna lead to an ERR CC board with a one pin connector?

So, I have to take this one baby step at a time. How does one attach an antenna lead to an ERR CC board with a one pin connector?

I am very good at sweat soldering water pipes! The smaller the connection required, the less skill at soldering I have! My trying to solder an antenna lead to a one pin connector on a PCB is a recipe for failure! The board will not survive!

There is nothing obviously wrong "under the hood" of my engine. I had hoped something might be obvious. The sensor "smushed" into the tach strip perhaps? Not so. All seems well.

So, how to proceed? A new ERR CC v.4.1 board is already on hand. Also a reed switch. No RailSounds board as it went into my other ailing engine. I will order another from ERR.

You probably have some of these connectors, just slide a wire out and use that to connect to the antenna. You do realize you'll have to solder at some point here, right?

You probably have some of these connectors, just slide a wire out and use that to connect to the antenna. You do realize you'll have to solder at some point here, right?