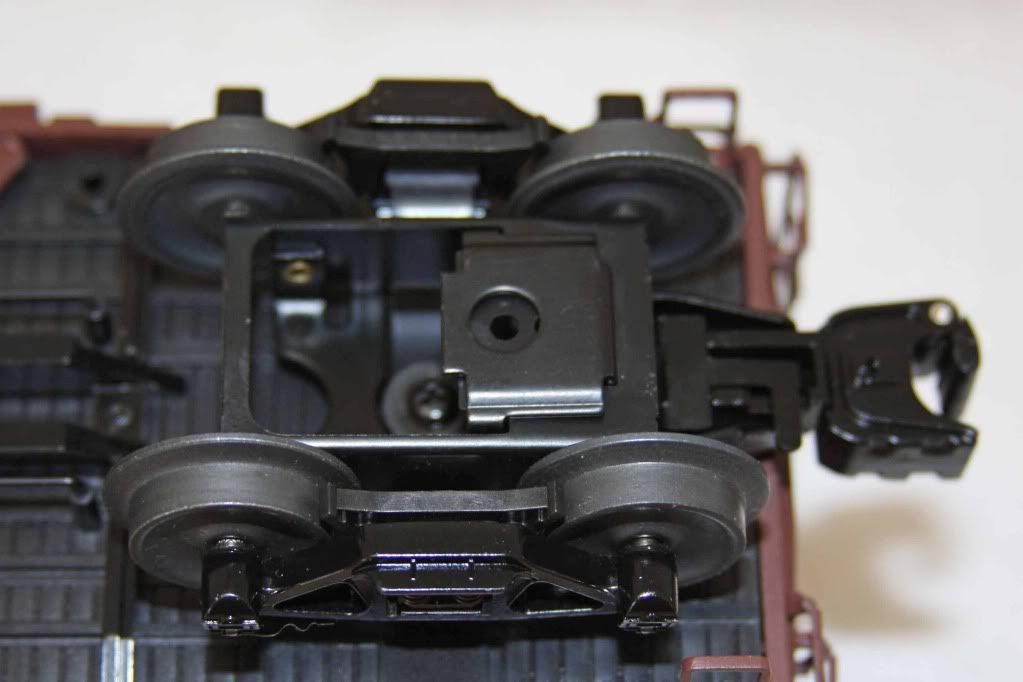

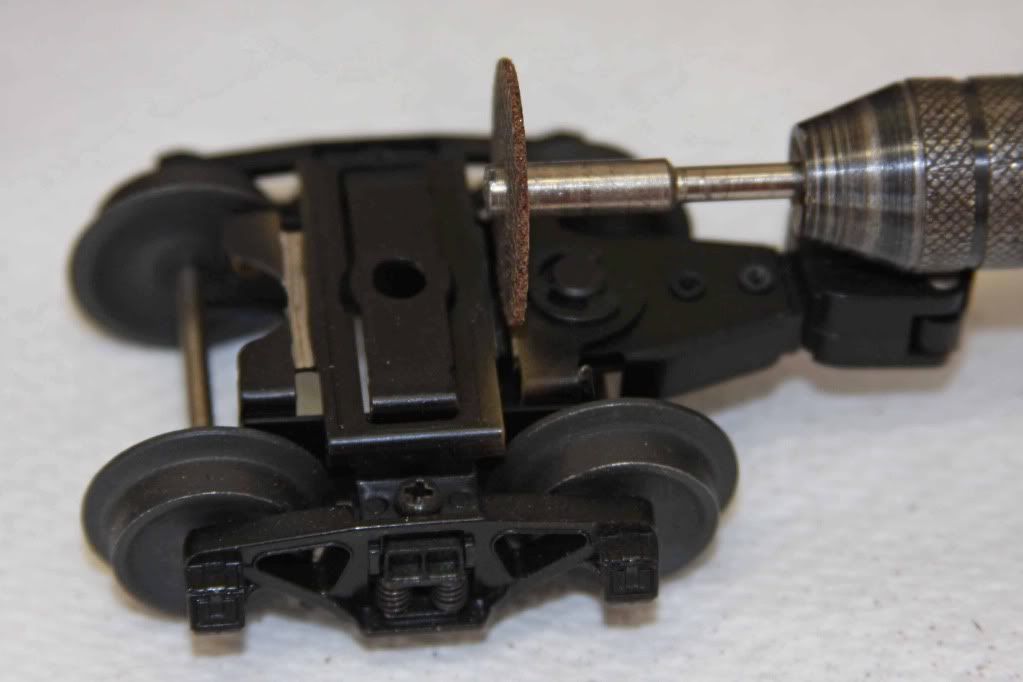

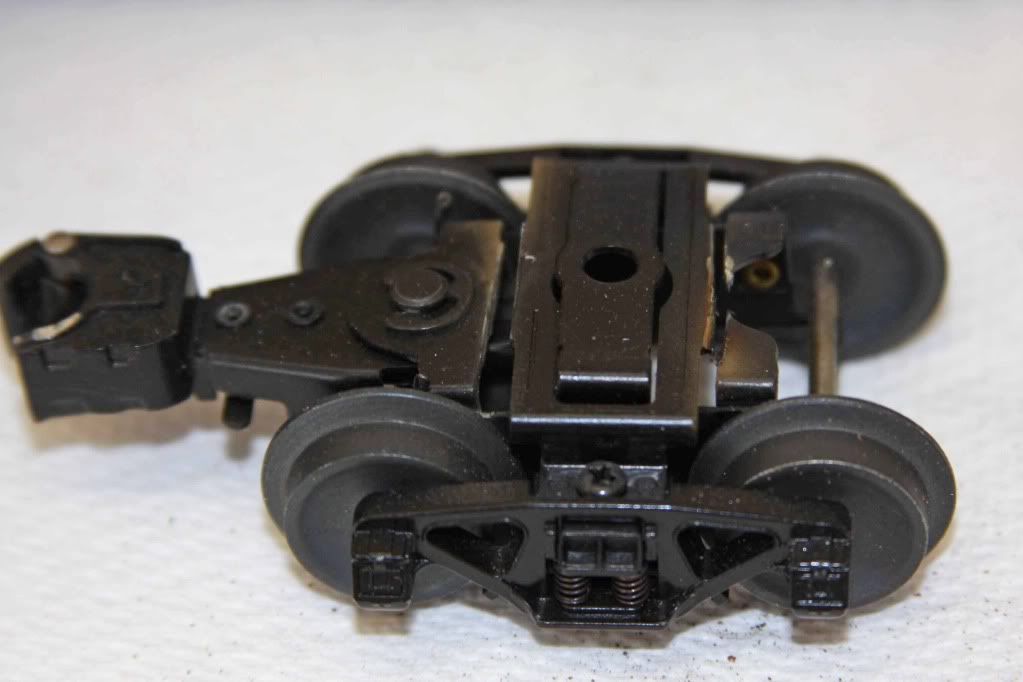

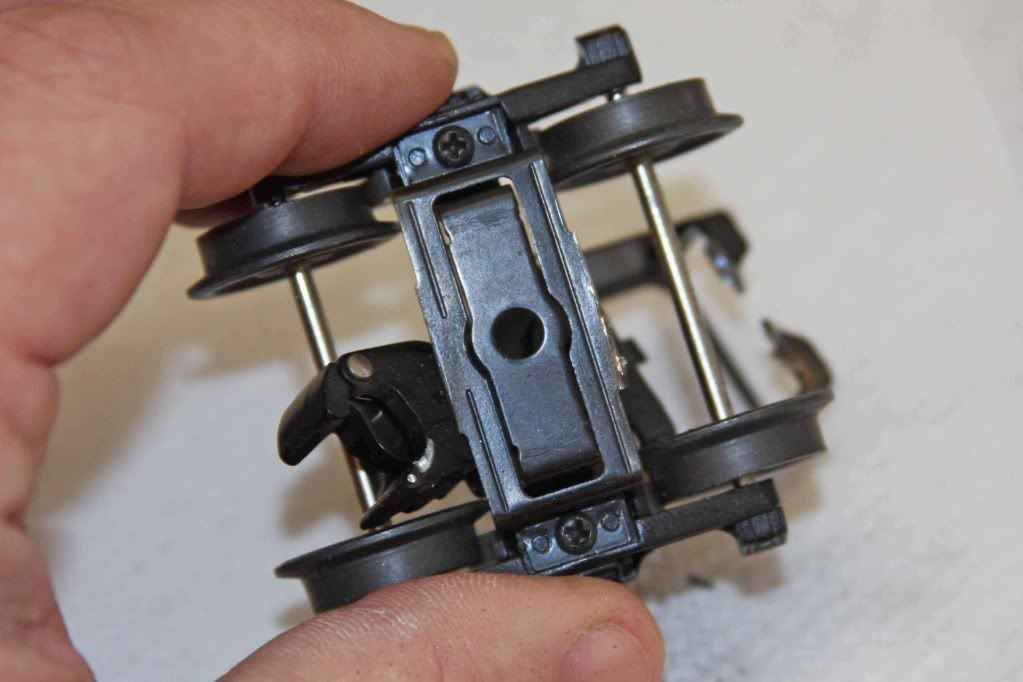

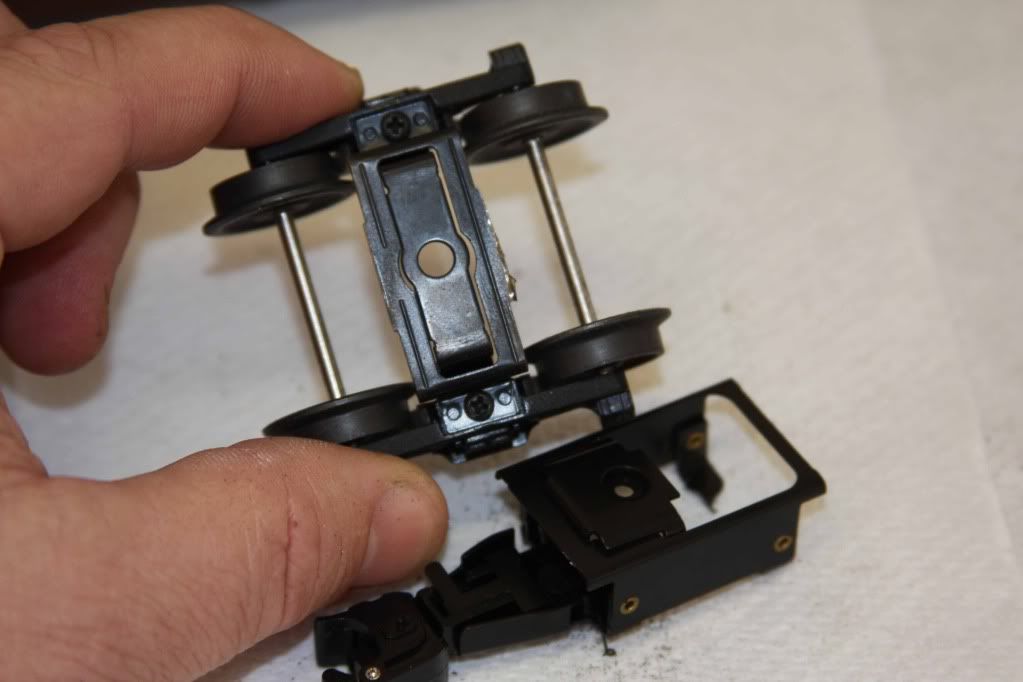

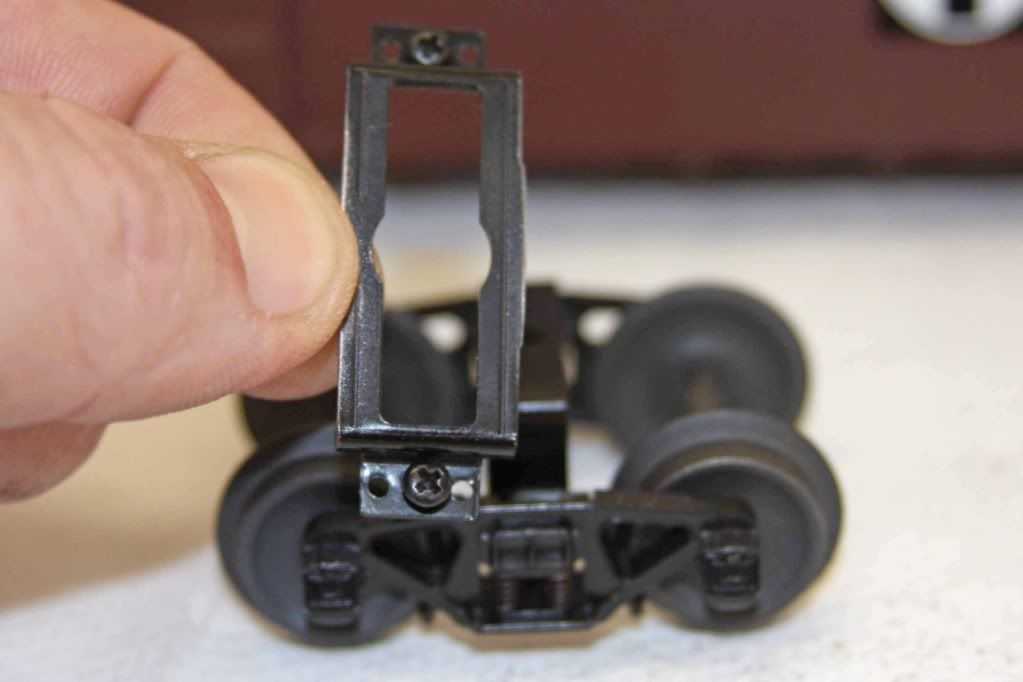

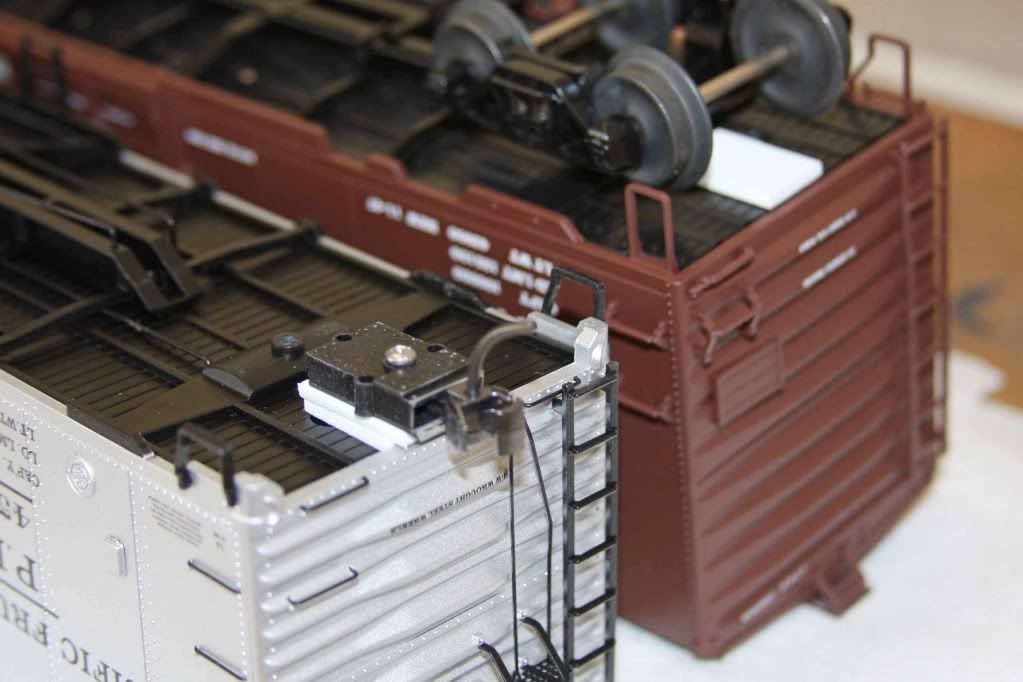

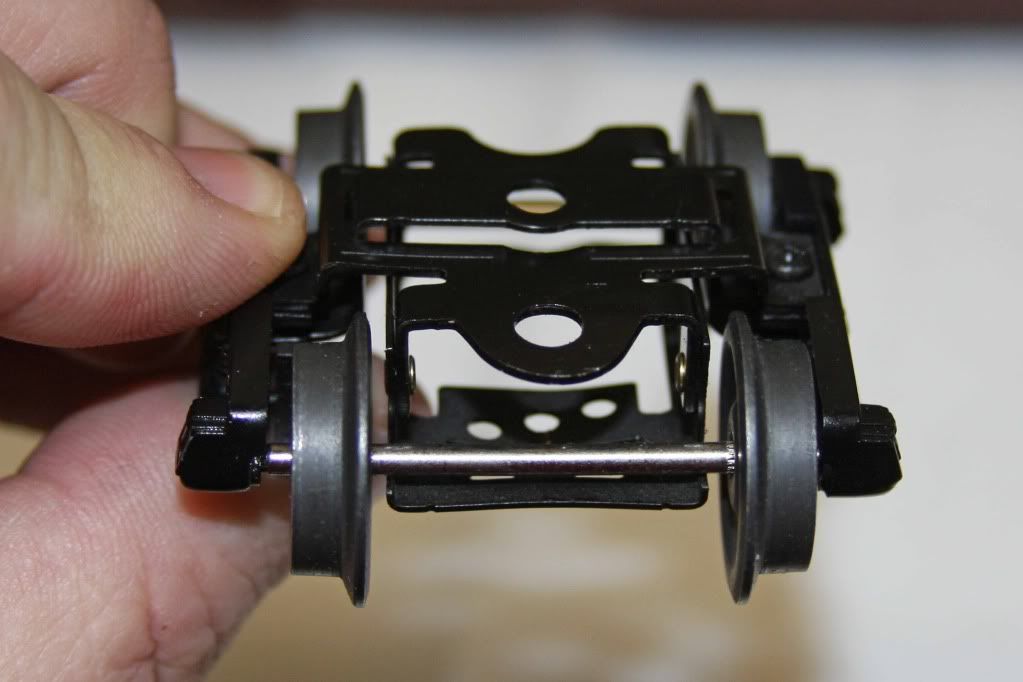

So far the Kaydee conversion for my Atlas, MTH, Kline and Weaver has been straight forward. One Lionel has been done and yes it is more of a challenge. Creating a"pad" to mount on is not too hard. Cutting the diecast coupler from the truck is a pain. Has anyone done this and what technique did you use? I read the thread on kaydee installation and only references to Lionel are made. In advance I thank you for your information.

Ray Marion

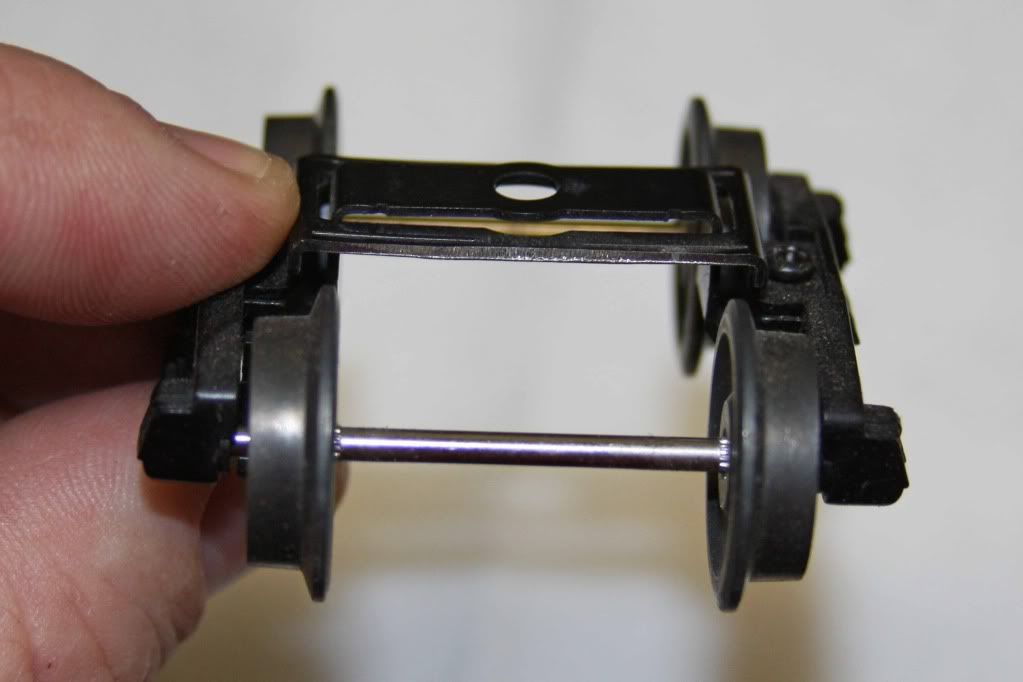

Original Post