My remote comes up after train is running MAINTENANCE REQUIRED ENGINE IS AMTRACK mth. Question is what do I do with the engine? Just Oil the wheels with 3 in 1 oil? Thanks again. Sonny

Replies sorted oldest to newest

You should oil the wheels and gears that turn the wheels.

Might have to reset your hand-held remote from MTH after doing this.

Barry B. would be best to tell you what is needed.

Lee Fritz

Lee is correct.

I'd just oil and lube the gears and the pickup roller axles, inspect the traction tires, and test the battery.

It's not necessary to do any kind of a reset.

FWIW, I recommend you do NOT use 3-1 Oil, it gets gummy after a spell. I use plain 10-30 motor oil, never gets gummy.

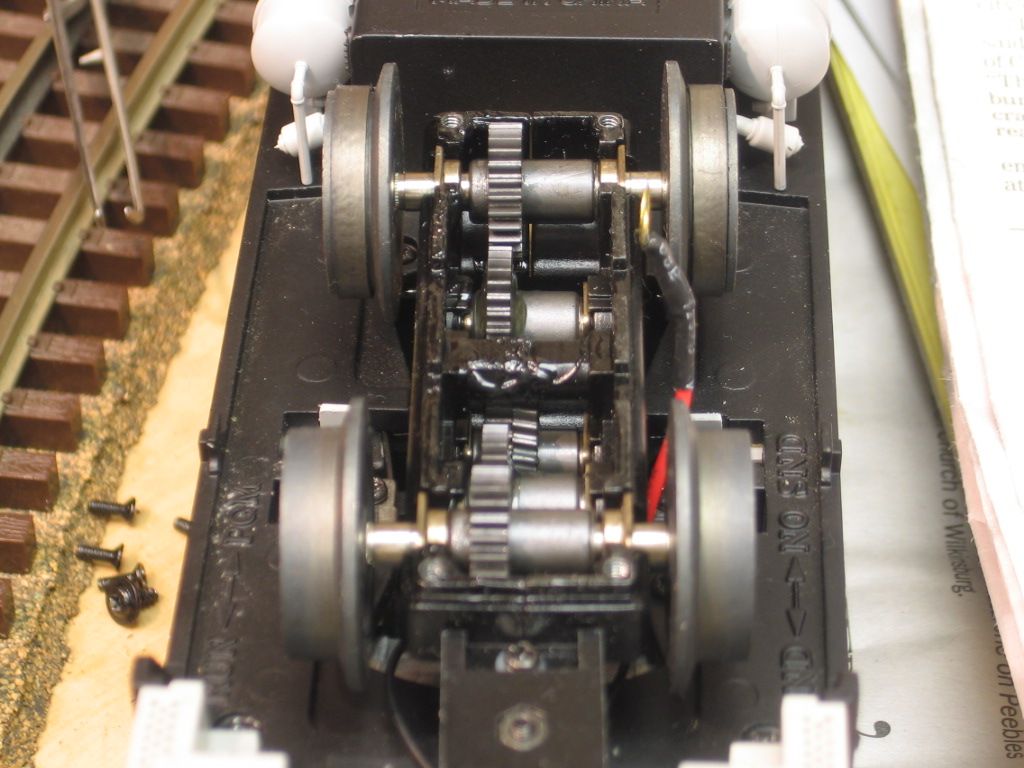

You want to be sure that the worm and drive gear(s) have lubricant on them. Gear box cover removed. This is a picture of an Atlas SW 9 drive. Note how the grease applied at the factory tends to be away from the gears. This is new out of the box. Not a lot of grease on these gears. The brass axle bearing(s) can be easily lubricated without removing the bottom gear box cover. Exposed gears along the outside of an axle block tend to pick-up dirt when heavily lubricated.

Thanks a million guys, Now that is a picture.(see my thread). I'll do as you say. Sonny

I would keep records of when a loco is lubricated. I find that I get the maintenance required message whenever the TIU and the loco have trouble making contact, as when I select a loco that's on an unpowered track. A loco can be over lubricated.

Lee is correct.

I'd just oil and lube the gears and the pickup roller axles, inspect the traction tires, and test the battery.

It's not necessary to do any kind of a reset.

I personally will disagree with Barry in that it may be a good idea to reset the maintenance "clock" in the engine. To do so:

Scroll through the softkeys to "more".

Once in the "more" menu, find "maintenance" and select.

Press whichever softkey the reset selection is above.

Now the "maintenance required" message won't come on for a while. I always do it - kind of gets in the way sometimes.

You do reset the maintenance warning after done, that way it starts the calculation over. Similar to cars that track engine oil wear. G

You do reset the maintenance warning after done, that way it starts the calculation over. Similar to cars that track engine oil wear. G

I don't follow the maintenance required pattern - I go over everything once per year - internal diesel gears greased, batteries tested/replaced, truck "outside" gears greased, oil around, etc. Again in the summer I do a smaller "touch up" on just the exposed gears and steam side rods. With the frequency (or lack thereof) that I run my trains, this has never been a problem. Plus with my very small locomotive fleet, this is also very easy to do.

SJC,

I personally will disagree with Barry in that it may be a good idea to reset the maintenance "clock" in the engine.

If you had paid closer attention to the OP's original post, you would have gleaned that I was referring to his statement:

Might have to reset your hand-held remote from MTH after doing this.