Having issues with all my never-before used MTH animated accessories. The latest problem is the car wash. I removed the bottom plate and confirmed all is in order with the two gear wheels and the drive chain. So I need to access the motor which appears to be accessed from the top. Does the building just pop off? I do't want to damage it. Thanks for any suggestions.

Replies sorted oldest to newest

I've taken mine apart, partly to repair the smoke unit with fresh batting. The building portion of the car wash is held down by screws, whereas the "glass dome" over the scrubbers on the drive just pops off. If you look where the 4 corners of the building are on the platform, you can figure out which screws are holding it in place.

Thanks Scott. I did just that and can find nothing amiss. Walking away from this task for a couple of days before I do some real damage.

what's happening when you activate the car wash? ..a description might help.

Not much to describe... the motor starts up like it's going to cycle the car through the was but there's no movement and then the sound stops. I removed the bottom and the three gears were clean and nothing stuck. I may remove the chain and clean it to rule it out entirely. I'm reluctant to wire up the gas station now out of fear of going three for three. ![]()

What I've what of done is first take each Accessory apart and clean all the grease out flush with fresh grease especially it never been run before and sitting many years the grease could have hardened causing it not to be able to rotate the gear mechanism! ounce you have lubricated everything then I would connect the accessory and try to see if it works normal!

Alan

This happened to me as well …when I reassembled the bottom of the base after examining the drive belt, I got motor noise but no motion. As it turned out, the unit is sensitive to how tight the base screws are; when I loosened it all the way … it all ran; I then screwed the screws in a bit , testing that it still ran, to find the sweet spot. Since mine was to be placed on the layout I wasn’t worried about tightening all of them to make it gorilla proof . Runs and smokes flawlessly now.

Attachments

Well count me in as jealous. Your video, and what I canb see of your layout, look great. Thanks for the added inspiration.

Well, I loosened all 35 base screws - not that they were overly tightened - and still no joy. Upon applying power there's a brief sound like the chain is skipping and then it stops. I've tried coaxing the stub that holds the car to no avail. The only other possibility I can think of is that the main drive motor is binding and not able to drive the gears. At this point I will need to get the accessories repaired by someone with more knowledge than me.

I got an old used one that didn't work. I had to file down the surface to create a gap so the large disc would turn freely. I believe something had grown over time and made it so it wouldn't spin.

I added some graphite powder and it's worked fine ever since. 2013!

1 fix 4 MTH car wash | O Gauge Railroading On Line Forum (ogaugerr.com)

@MorgoNJ posted:Well, I loosened all 35 base screws - not that they were overly tightened - and still no joy. Upon applying power there's a brief sound like the chain is skipping and then it stops. I've tried coaxing the stub that holds the car to no avail. The only other possibility I can think of is that the main drive motor is binding and not able to drive the gears. At this point I will need to get the accessories repaired by someone with more knowledge than me.

The gear boxes all have a spring based clutch system to prevent damage. It just means the motor and gearbox are trying to move and the final output cannot move something external. Again, that sound means motor and gearbox are good and working, and you have something jamming- likely external- the final output.

Also note- said it before but the garage door opens on all of these BEFORE the vehicle motion happens to prevent slamming into the door.

Vernon, what might be "jamming" the gears externally? Did you have anything in particuliar in mind? I haven't added the unit to my layout yet. I like Engineer Joe's suggestion of using some dry lubrcant on the two large gears and chain although less than excited to open this beast back up for the fourth time. Hobbies are suppossed to be relaxing. It's good I'm retired as I have nothing but time.

I would unbolt the motor/gearbox from the base, attempt to move the chain and car ring gears manually, and figure out where the friction is. Gearboxes are only held to the base with 3 screws.

Thanks Vernon, I hope to get to this tomorrow. I really appreciate your continued interest and suggestions.

Not sure if someone linked or you saw this- but there are some great resources out there.

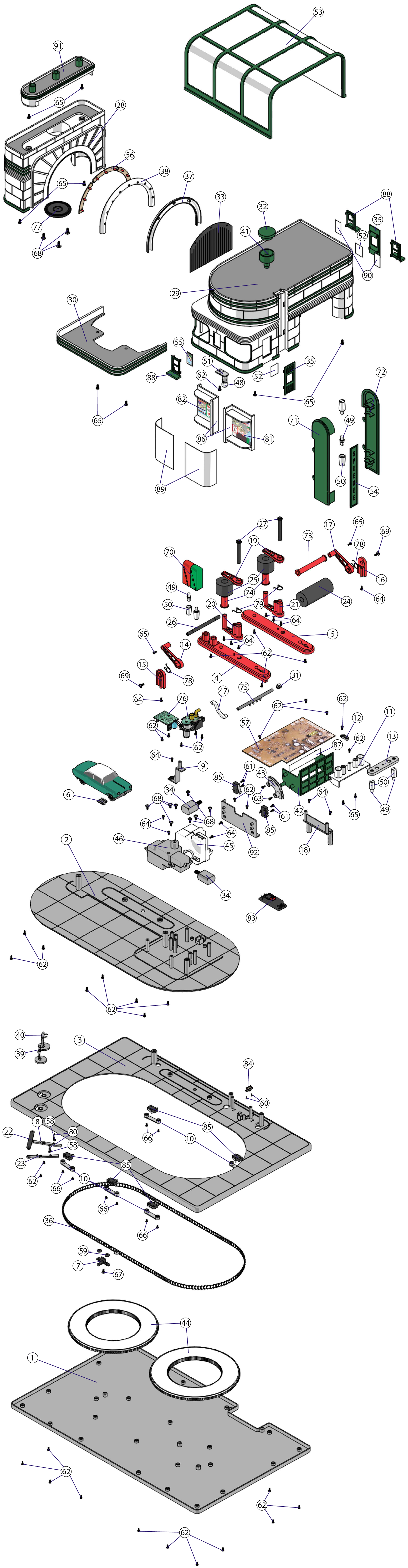

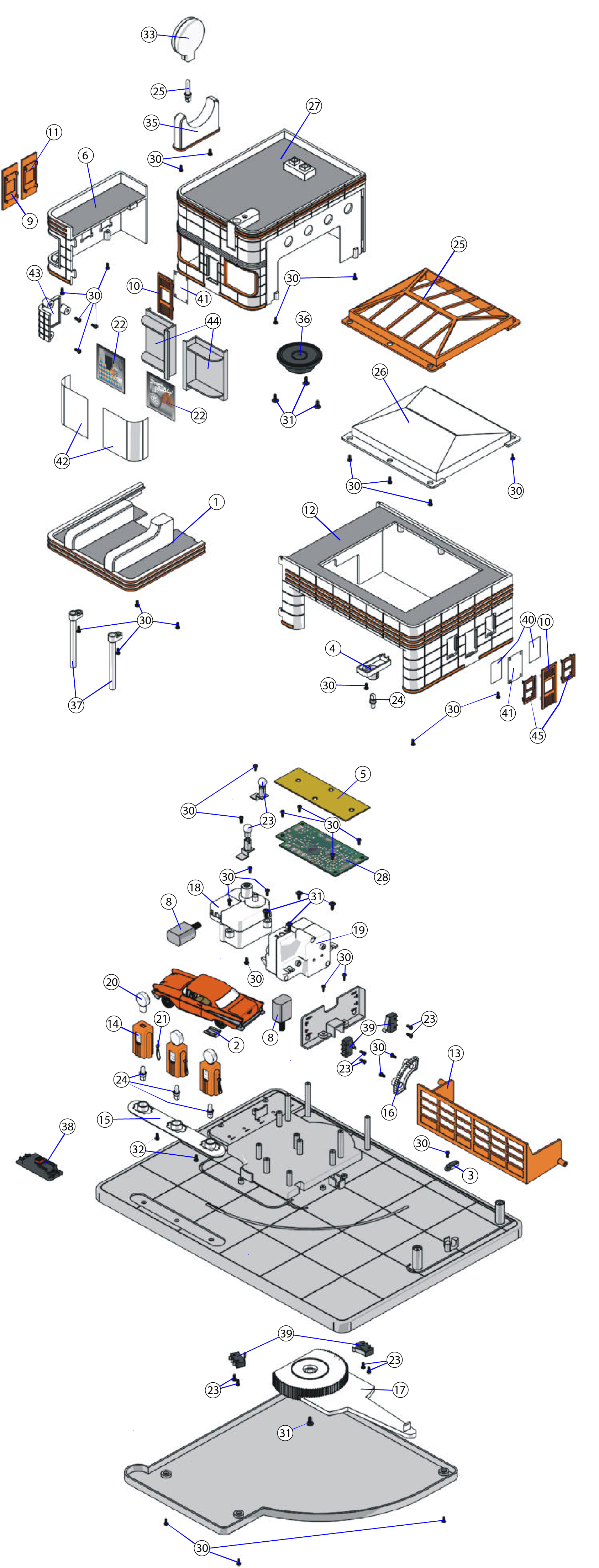

RAILKING CAR WASH- diagrams and parts listing from MTH parts and sales.

https://www.mthpartsandsales.c...lists/270?type=lists

Gearbox and motor 46 is the one for the car movement. As said before, there are only 3 screws holding it to standoff posts molded into the base. If you lift the gearbox out- then the car and chain and large sprockets can be moved by hand. The gearbox is just poking it's output gear through a hole in the base to make with the large ring gear and sprocket. Again, removing this just slightly upwards then allows you to directly get a feel for the load the motor and gearbox is seeing trying to move the track.

FWIW, both Nylon and ABS types of plastic absorb moisture right out of the air and this can cause the plastic to expand and swell slightly changing dimensions. That could be why something is binding- many years of soaking up humidity and it all just tightens up. Being plastic on plastic, not the best ideal bearing surface for minimal friction, once it begins to grab friction increases dramatically, hence lube of either plastic safe grease or possibly a tiny bit of graphite yes could make a dramatic reduction in friction.

I was trying to see which topic was best but the gas station since I know you have that too.

https://www.mthpartsandsales.c...lists/268?type=lists

In this one, once again the vertical output gearbox is the one that drives the vehicle motion arm, the other motor and gearbox is for the door.

#17 is the long arm and gear that is the car motion.

The nylon gear can shrink with age binding on the base. If the motor isn’t turning or skipping against the clutch, the diameter needs to be increased to work correctly or replace the gear.

Attachments

here is the car wash gear part number EG0000019 from MTH! Alan

Attachments

This is terrific information from everyone, thank you! I'm afraid some of it may be beyond my aging abilities. I'll endeavor to remove the motor this week and see if anything is binding, but beyond that, I'll be looking for a repair facitity with the ability to fix it. Recommendations on a Jersey-based repair shop would be welcome.

The Train Doctor in Ocean, NJ.

Hi check your email I can repair it!

Alan

I have 7 animated MTH accessories and the only one that works is the fire house. The gas station only lights up. The door don't open and no sounds. I tried to buy a new one on E Bay, after 4 brand new gas stations did not work I gave up. My car wash stopped working, after a few hours I was able to get the car to move but no sounds. Same with Mels diner no sounds but the car does work. The Amtrack train listing does not work at all, I was sent parts that were available but it would still not work. I replaced it with the Lionel train listing I had since the 50's. I have the MTH Gateman that never worked, because I bought it from someone that was not an MTH authorized dealer I had no recourse. The last problem was the MTH gates one works perfect the other don't work at all. MTH did not have any gates in stock they could not replace it. I am glad they still light up.

Yikes… MTH is letting us down. My Gas Station, although sitting on the shelf for the past 25 years, worked right out of the box. But as reported earlier, the Fire House and Car Wash both didn’t work even with a good cleaning. Alan Mancus is trying to revive them for me.

If the main drive gear shrinkage (Jon G) is a fundamental problem, I don't know why purchasing a replacement part, alone, would be recommended. The numbers seem to suggest this is not a new/old problem, but a basic design issue related to the environment (e.g., humidity and its variations in each owner's setting...storage or layout, controlled or not, etc., etc..) and its effect on the gear material over time. Nylon is a very hygroscopic material...qualities/dimensions affected by water...humidity...excessive and/or the lack thereof...and variations over time. Cheap?, of course!...that's why it's chosen for choo-choo toys. A new gear of the same material and molded from the same die put into the same environment is going to end up doing the same thing over time...shrinking to inoperative...IMHO, of course.

Sounds analogous to the decades-old, ubiquitous issue of splitting nylon gears in the hobby's drivetrains...locomotives of any scale, and accessories alike...which spawned a significant portion of Northwest Shortline's (NWSL...The gear folks) business...providing replacement gears of metal or acetal to replace those prone to splitting. Of course, in this case, the design of the MTH accessory gear undoubtedly won't split like a wheel axle gear...the 'hub' portion of the gear is far beefier than an axle gear at its root dimension. But there's nothing to inhibit its shrinkage...short of molding the part of a non/lesser-hygroscopic material...like acetal resins...which would probably necessitate major die re-work or replacement due to the significant difference of in-process shrinkage of nylons vs. acetals during the molding. And, BTW, there's little-to-no chance that NWSL would have offered a replacement for such a unique accessory gear!!![]()

Don't know how Alan deals with the problem (trade secret!![]() ), but he would be my 'go-to' were I in the same situation.

), but he would be my 'go-to' were I in the same situation.![]()

Or, per JonG's suggestion...and not having a lathe...I'd see what I could do to improve the hub-to-gear fit to relieve the binding. FI, I have a burr scraper, an inexpensive hand tool that might, carefully,shave the i.d. of the subject gear sufficiently to allow it to freely rotate around the hub. It'd be worth a try, methinks.

I'd be careful in the use of a lubricant in this situation. A dry silicone spray might be OK, but there's too many 'lubes' that might exacerbate the problem, rather than relieve or solve it. Again, IMHO.

At the price of these popular, albeit monster!, accessories, I couldn't walk away without finding a solution...that's for sure!

FWIW...

KD

When does the smoke unit activate when the car wash turns on? Is it when the car enters the opening(garage)? Is there an on/off switch for the smoke unit?

The car wash at my club operates five but never added fluid to the unit. Going to see if I hear the fan going and/or feel heat from the stack or see any smoke billowing if I added fluid.

It is a cool accessory!

Morgonj- where are located in New Jersey? My club is in Lakewood NJ on the Jackson/Howell border.

Ted, I live in East Hanover (Eastern Morris County), so your Lakewood club is quite a distance from me.

@Ted Bertiger posted:When does the smoke unit activate when the car wash turns on? Roughly after the car begins moving after the ordering window.

Is it when the car enters the opening(garage)? Yes, when it is entering the wash garage door area just after leaving the order area at the window. It's supposed to simulate the water spray vapor and steam from the high pressure washing area.

Is there an on/off switch for the smoke unit? Yes, on on the bottom of the base.

The car wash at my club operates fine but never added fluid to the unit. Going to see if I hear the fan going and/or feel heat from the stack or see any smoke billowing if I added fluid.

It is a cool accessory!

@ScottV posted:I've taken mine apart, partly to repair the smoke unit with fresh batting.

Scott, have you ever considered adding a switch to warm up the smoke unit before activation so the "steam" will billow out with the first activation of door?

@Susan Deats great idea! I could add a timed relay to build up smoke before activating the rest. … definitely on to my to-do list

thanks!