Martin mentioned that the brass pieces were chemically etched. I didn't know and asked Glenn Guerra, Mullet River Models.

Glenn's email.

Mike

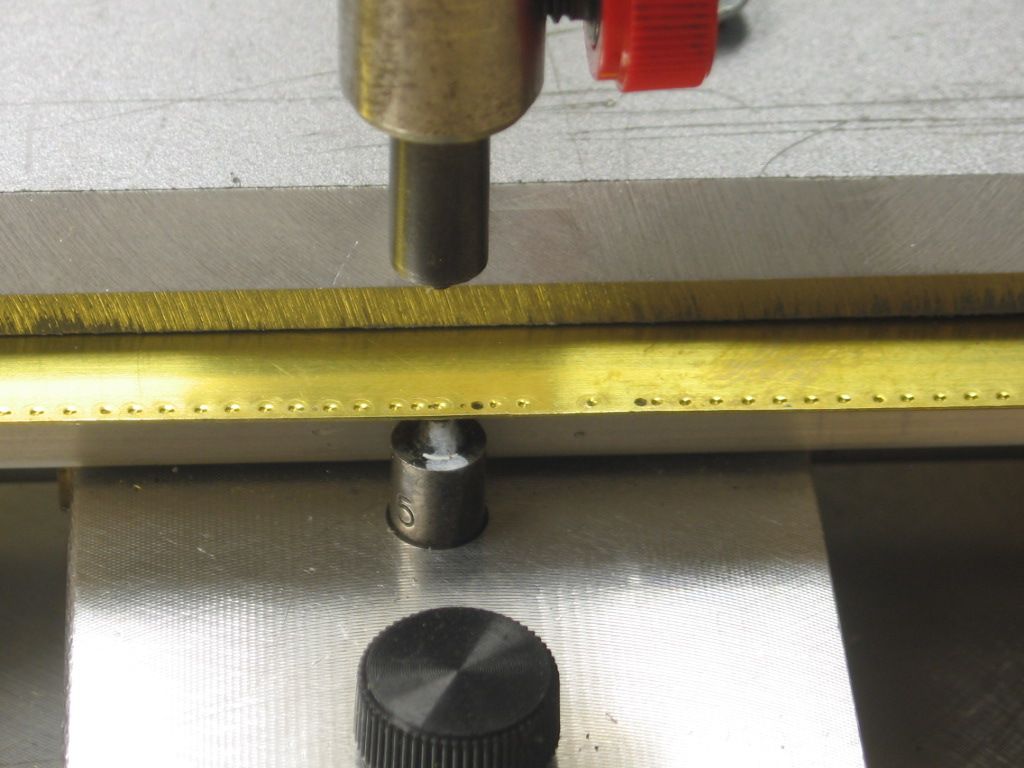

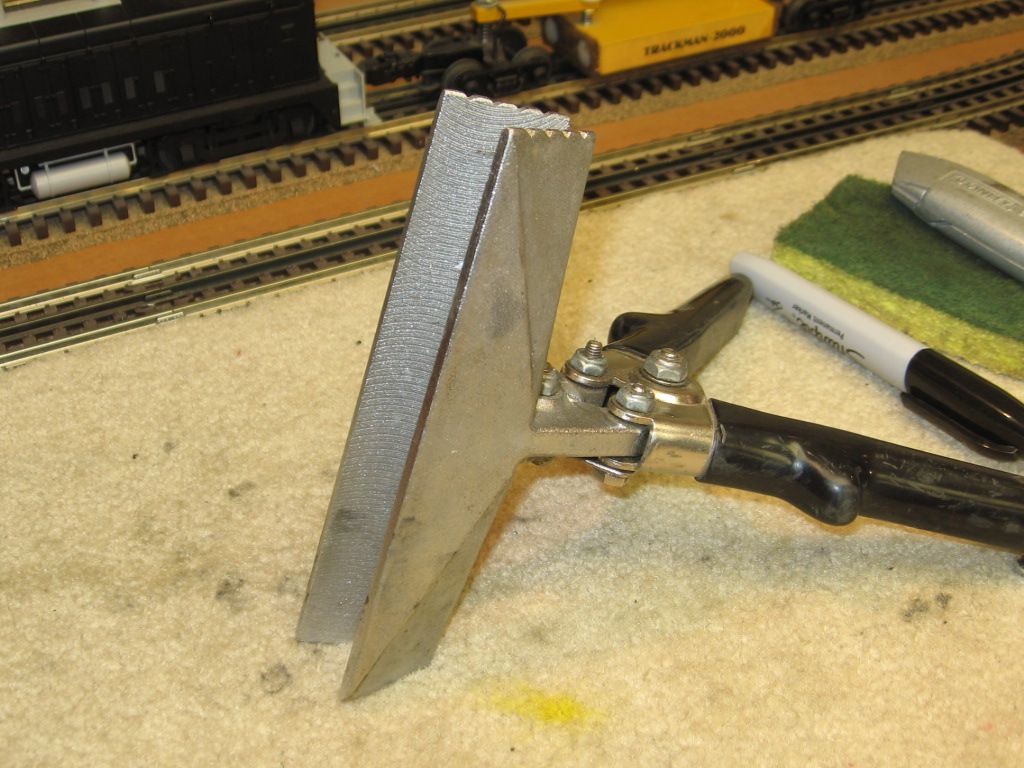

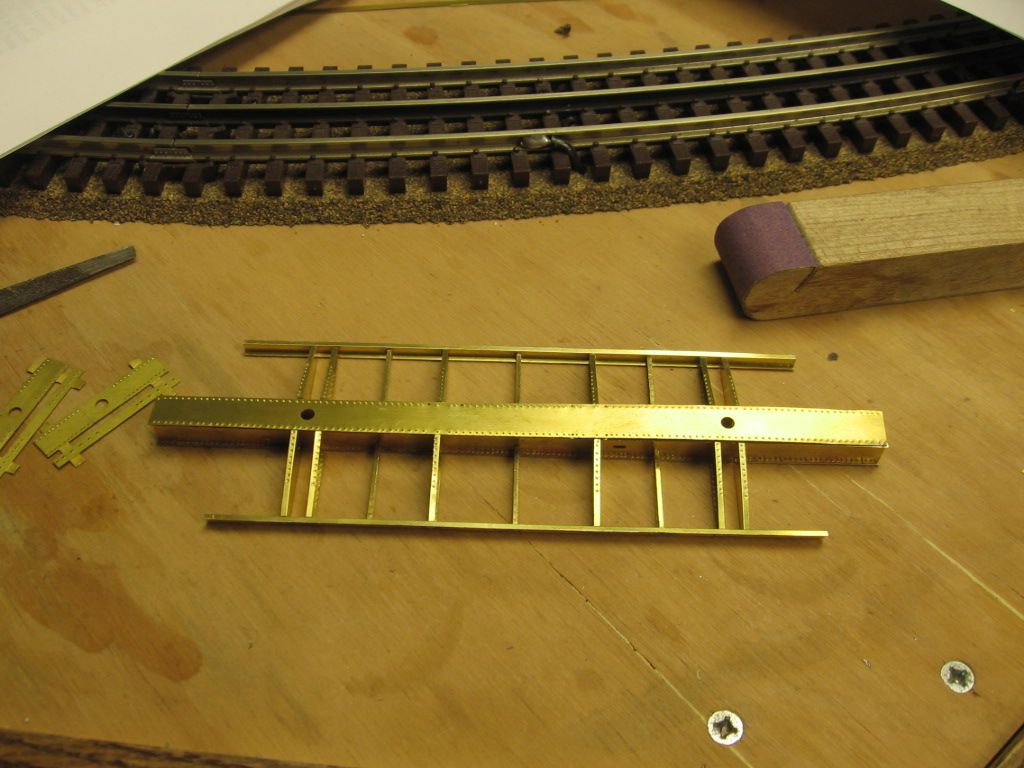

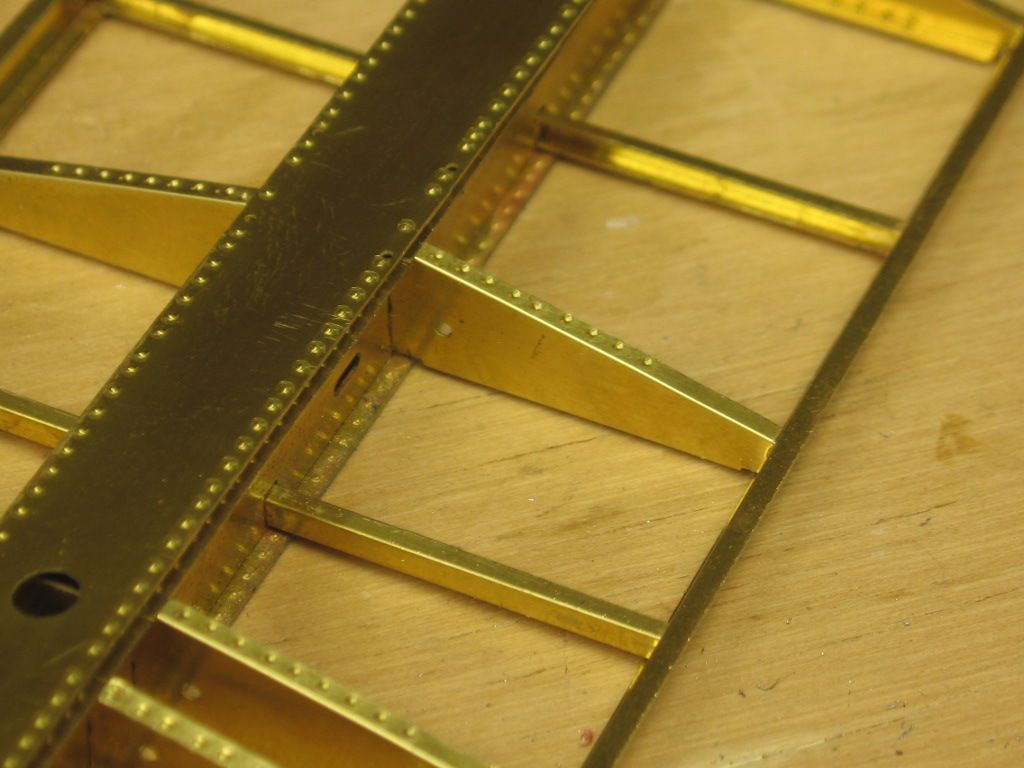

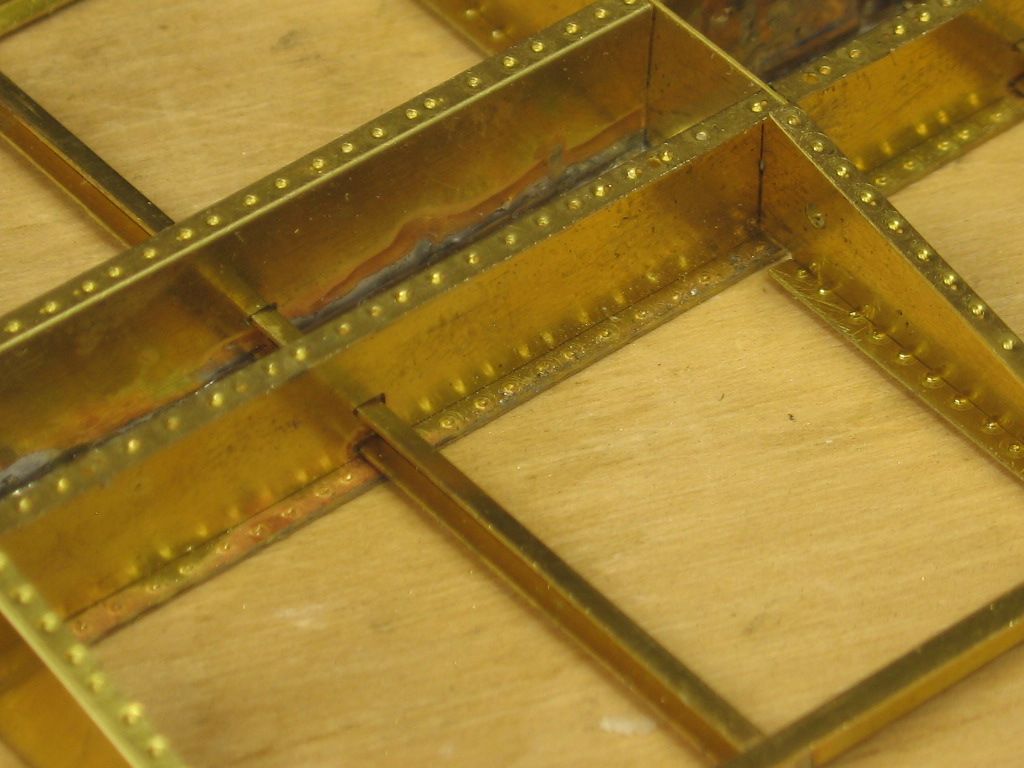

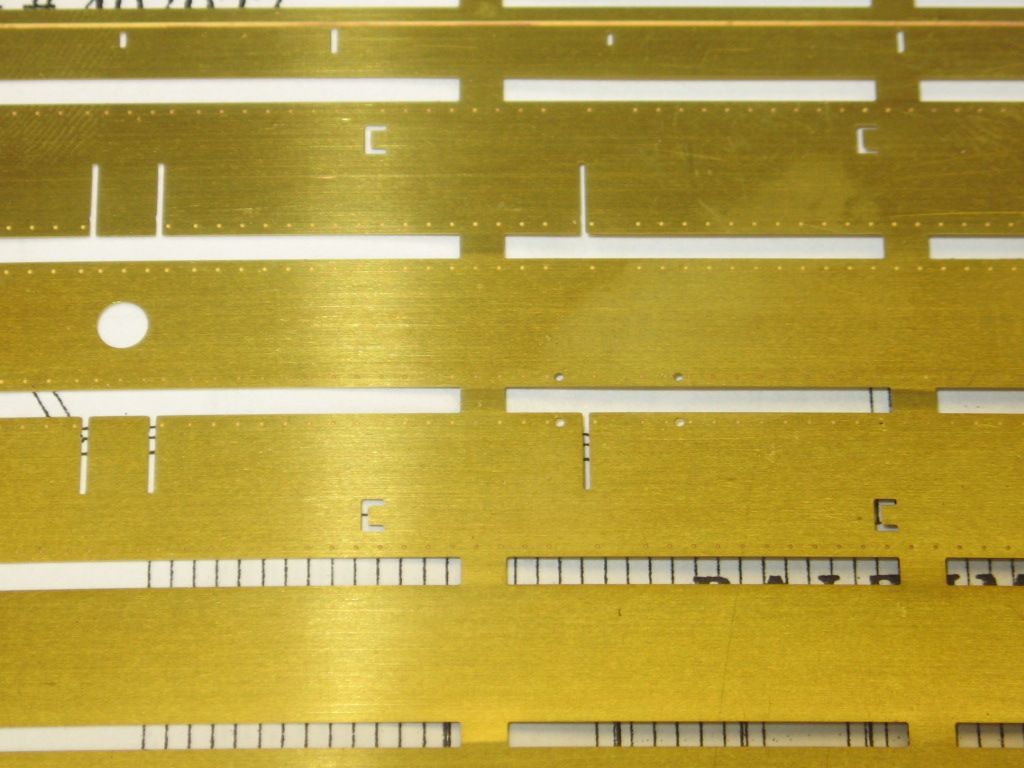

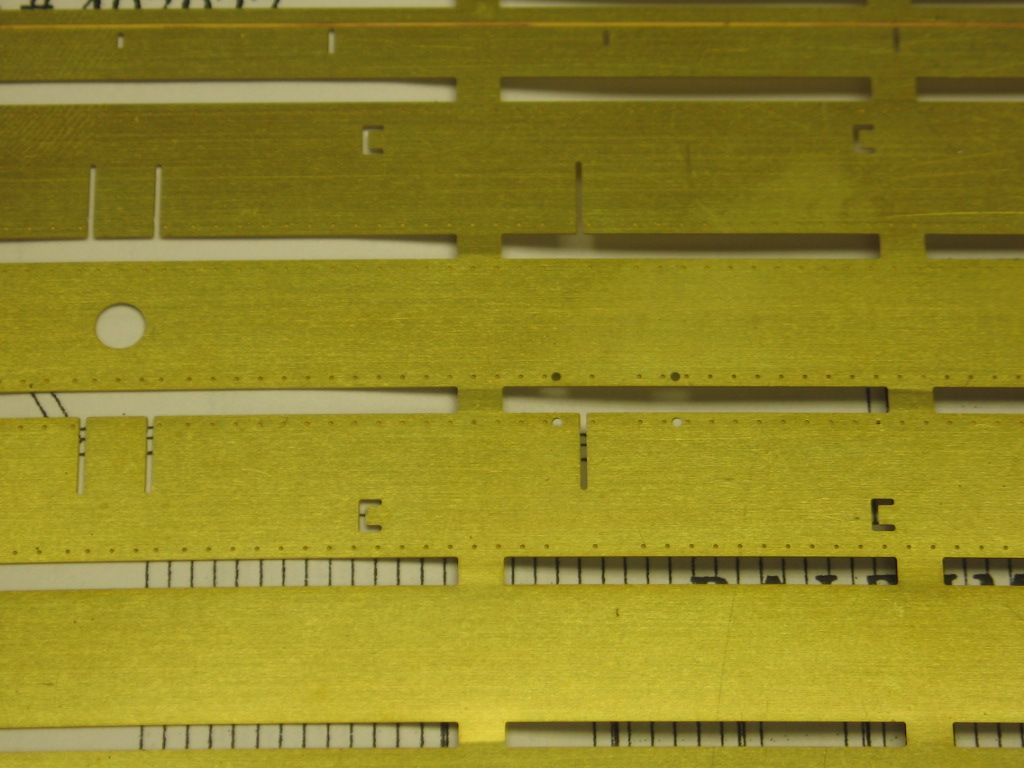

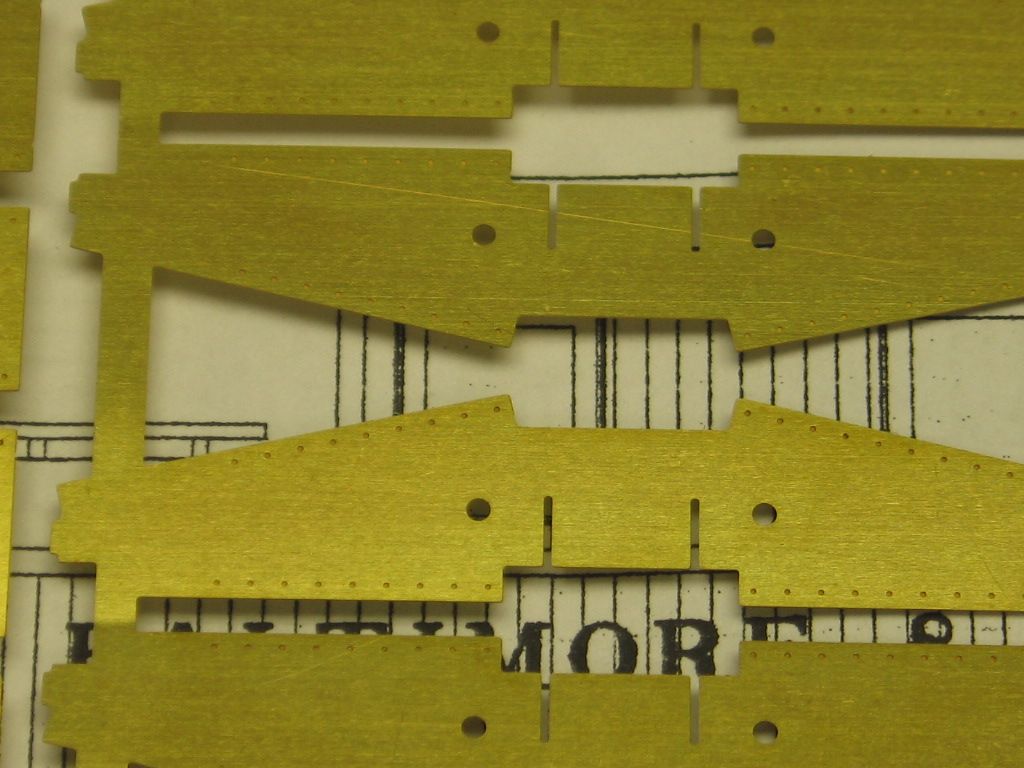

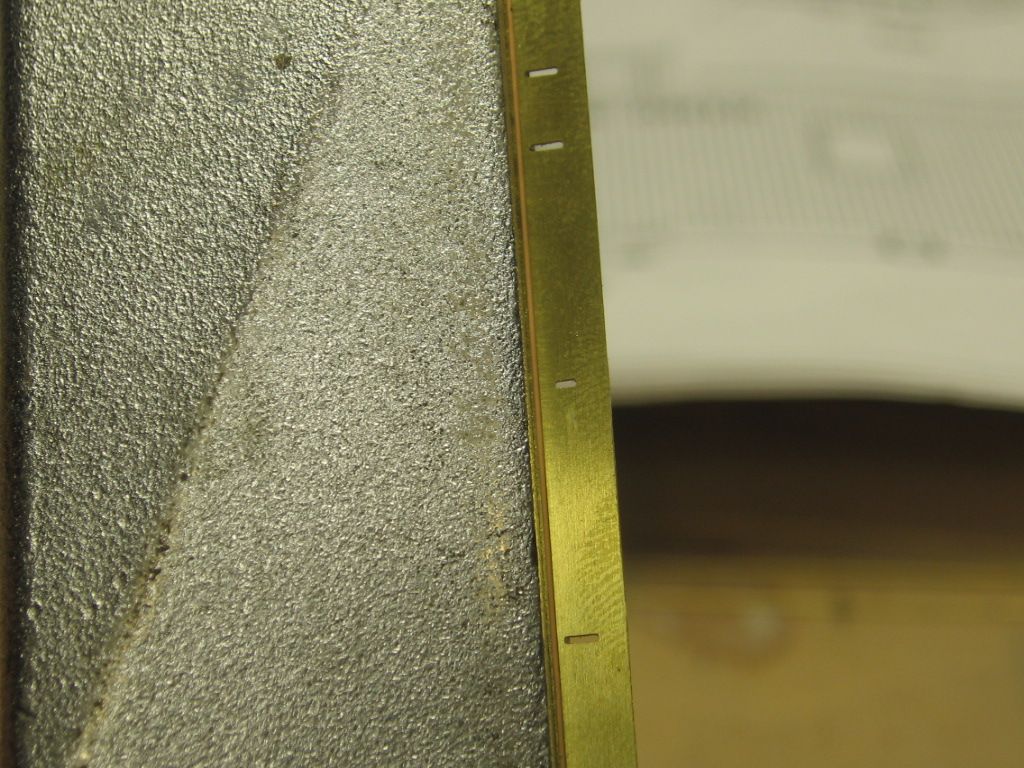

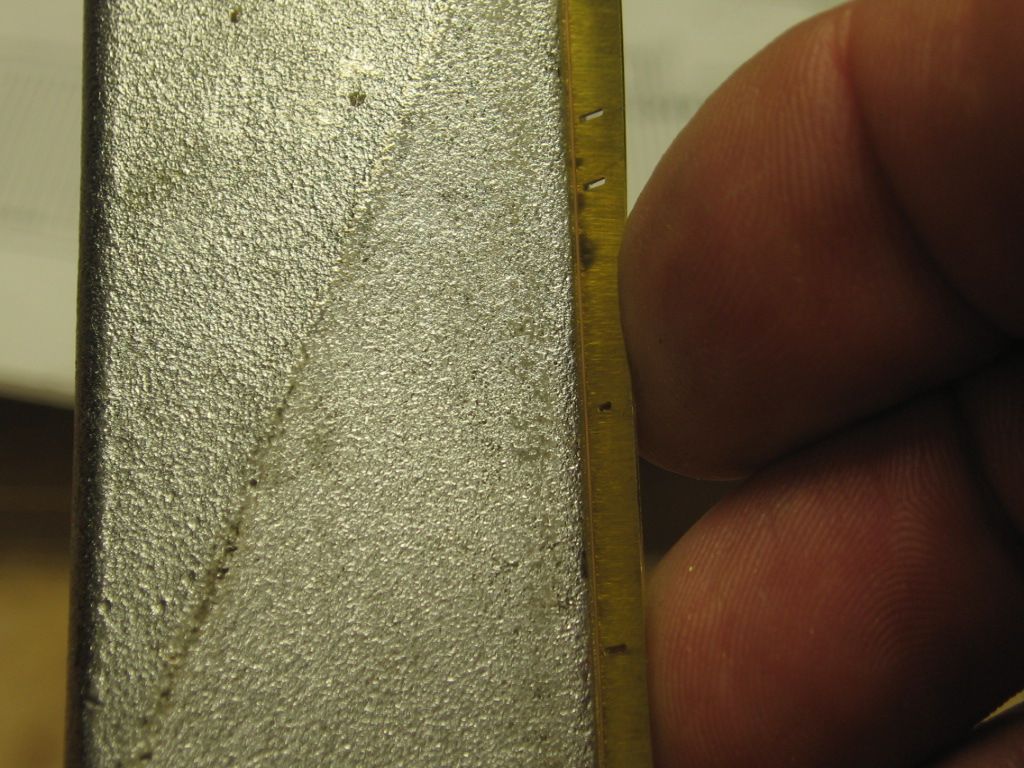

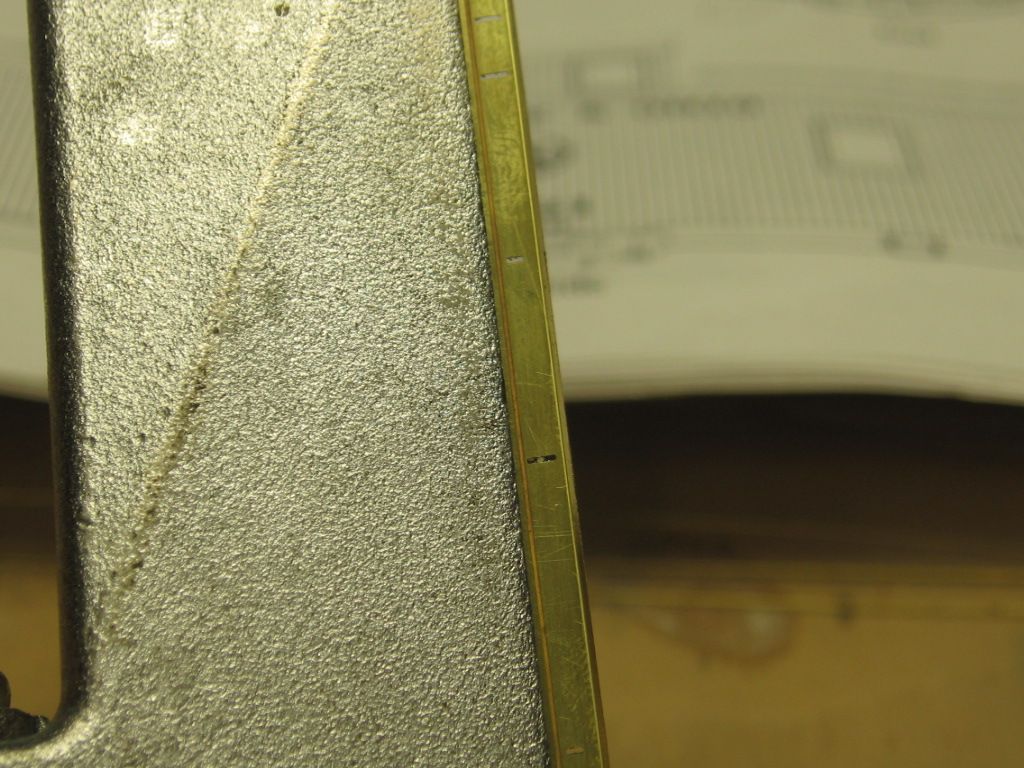

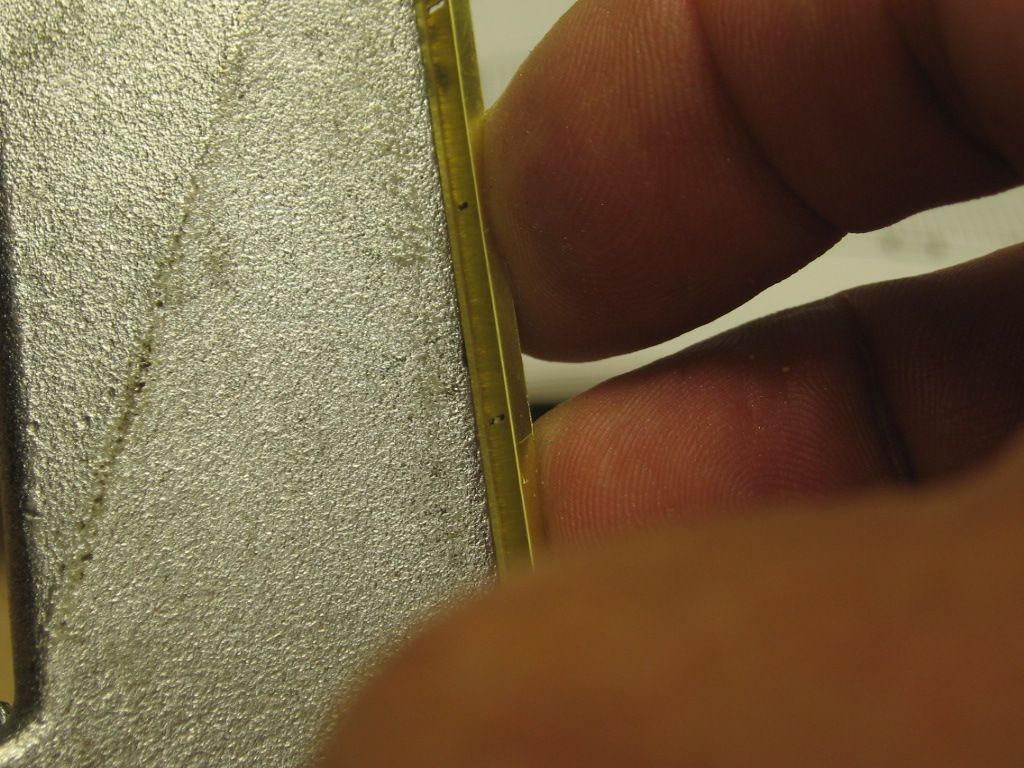

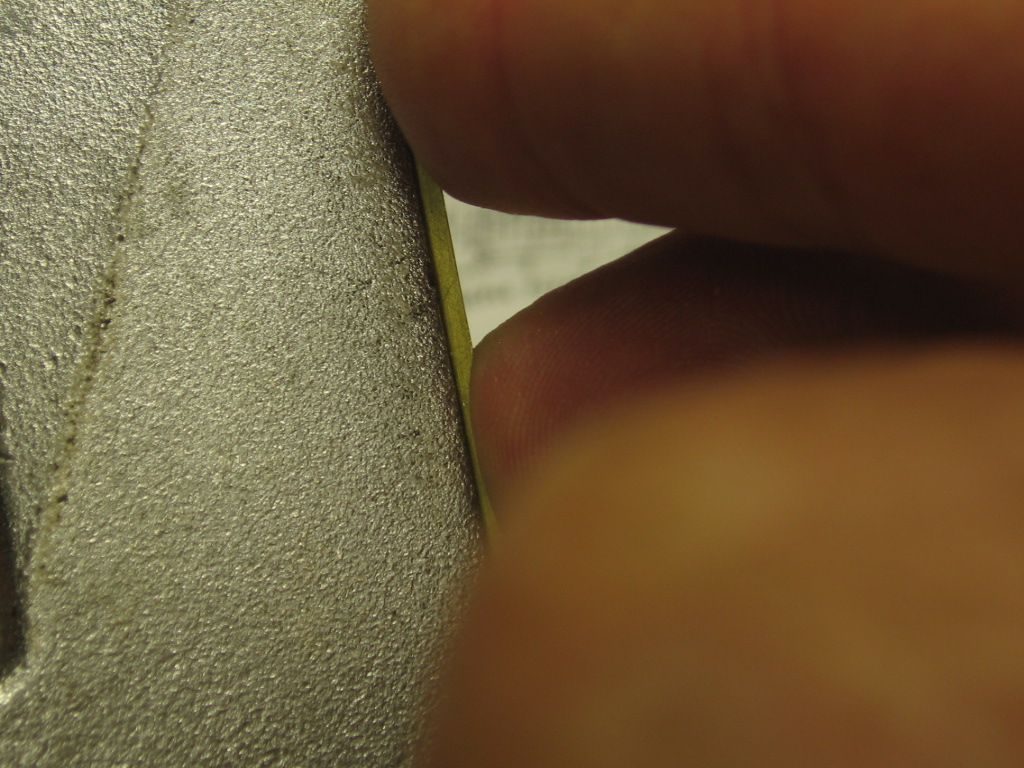

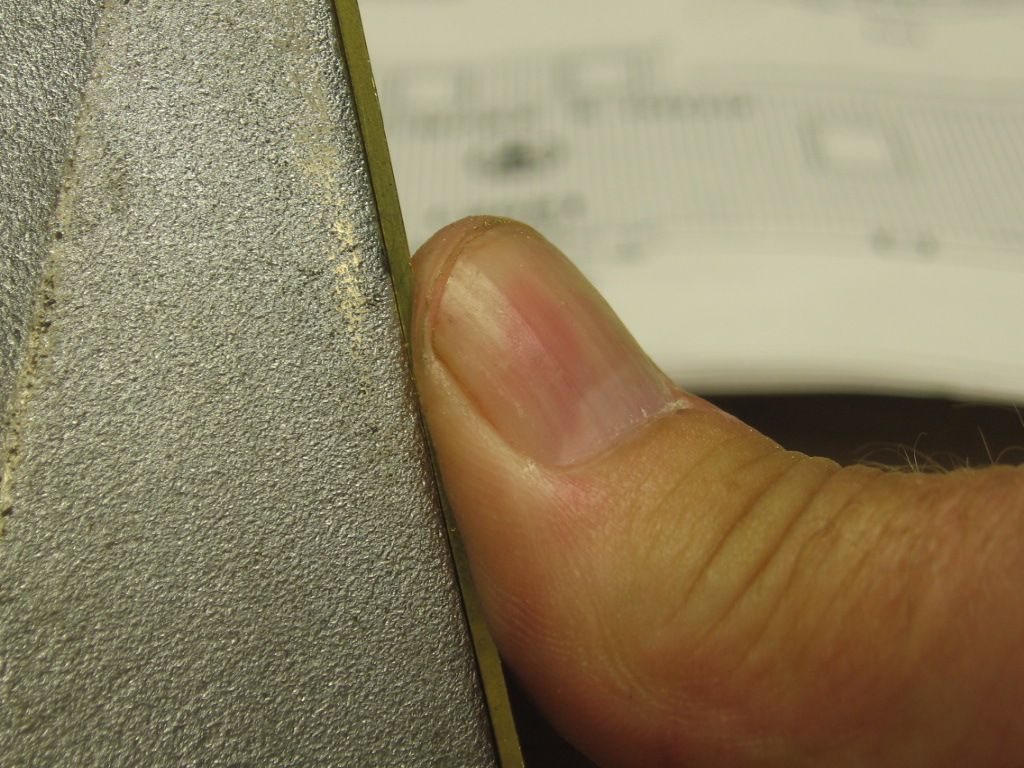

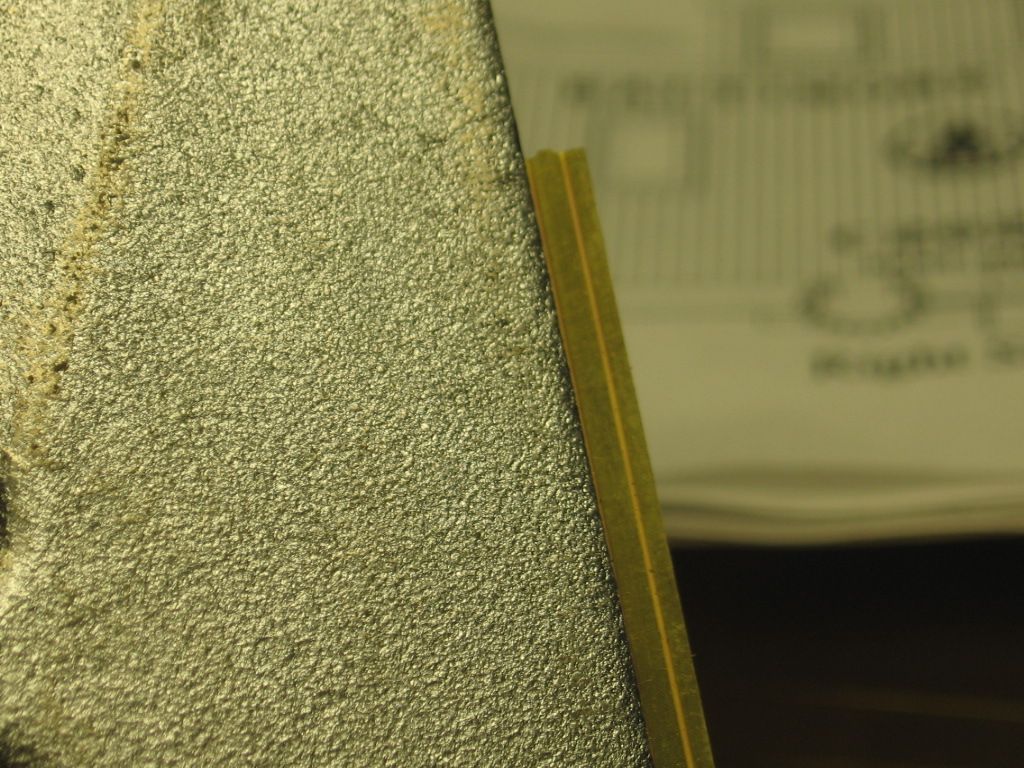

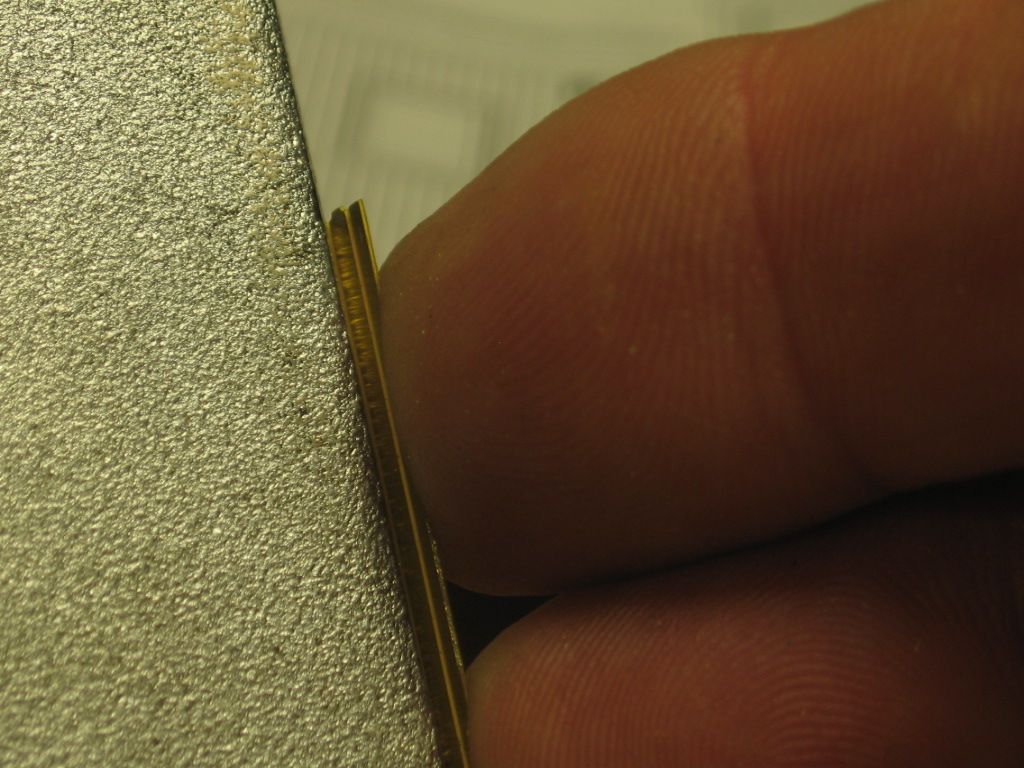

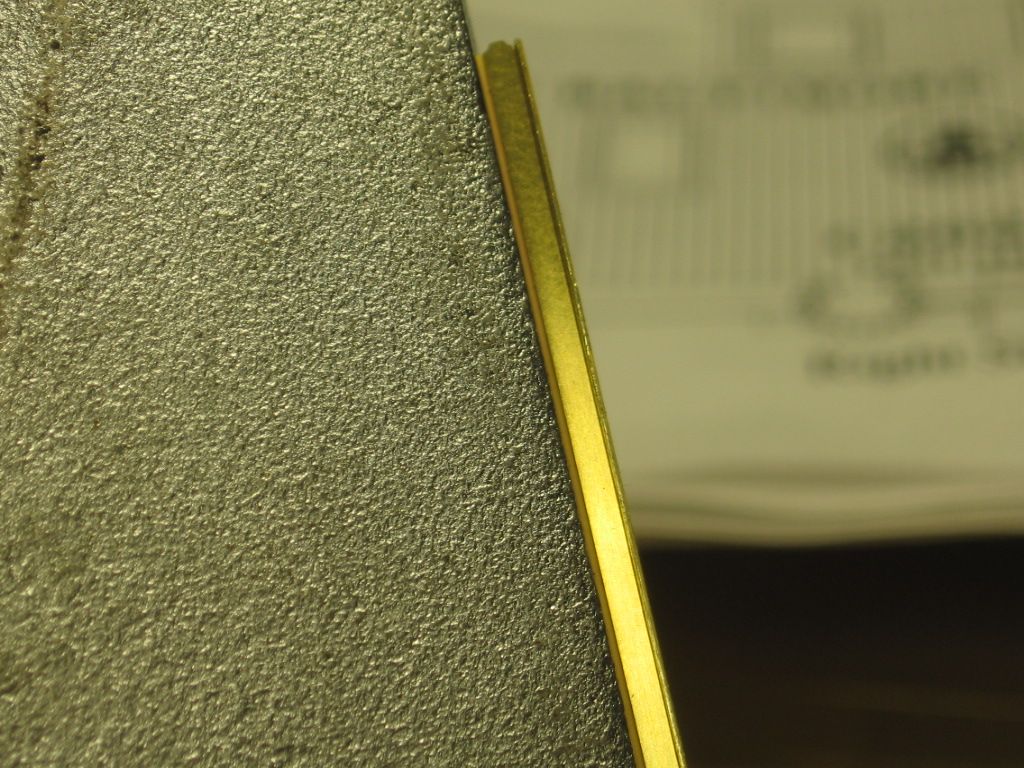

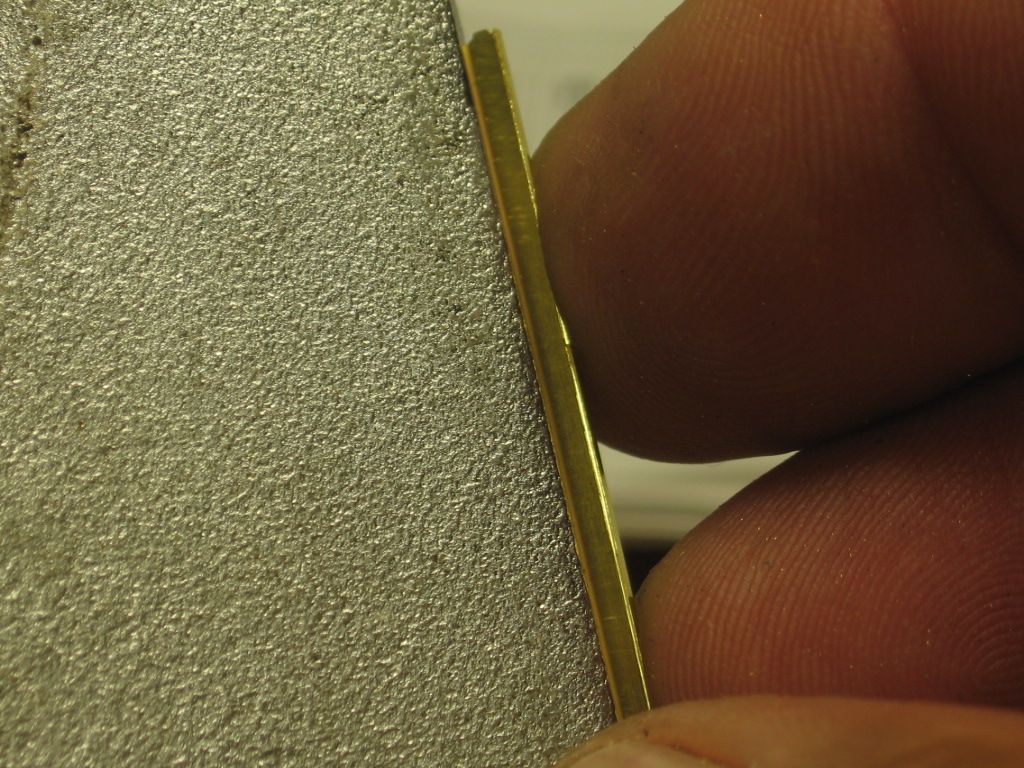

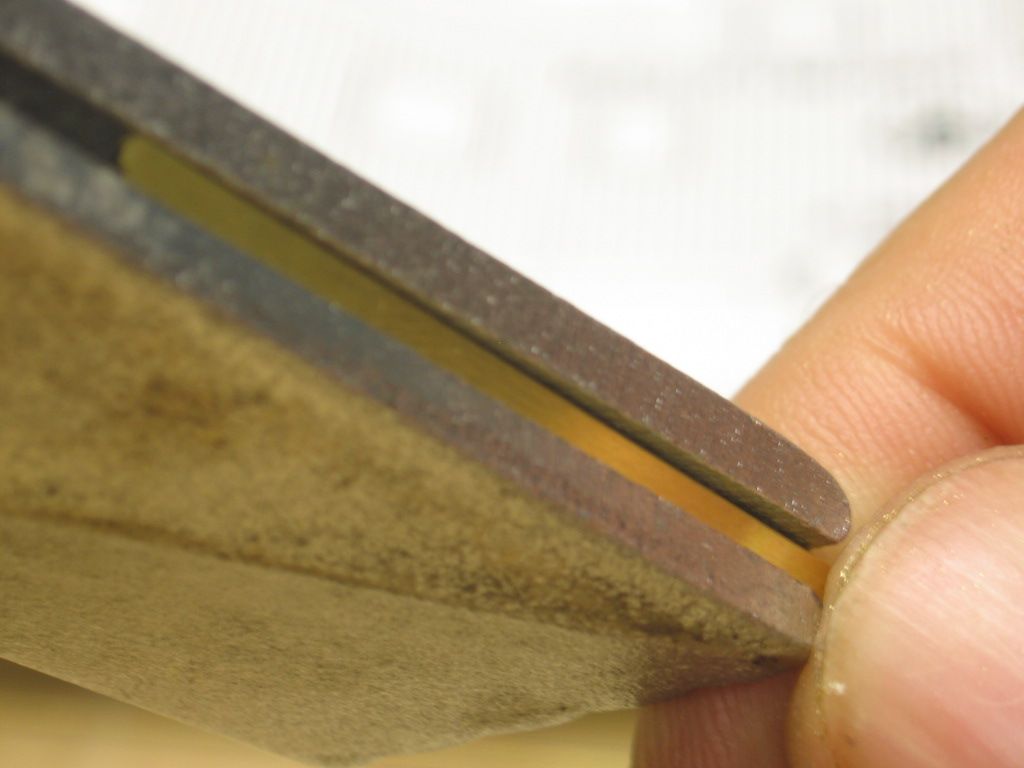

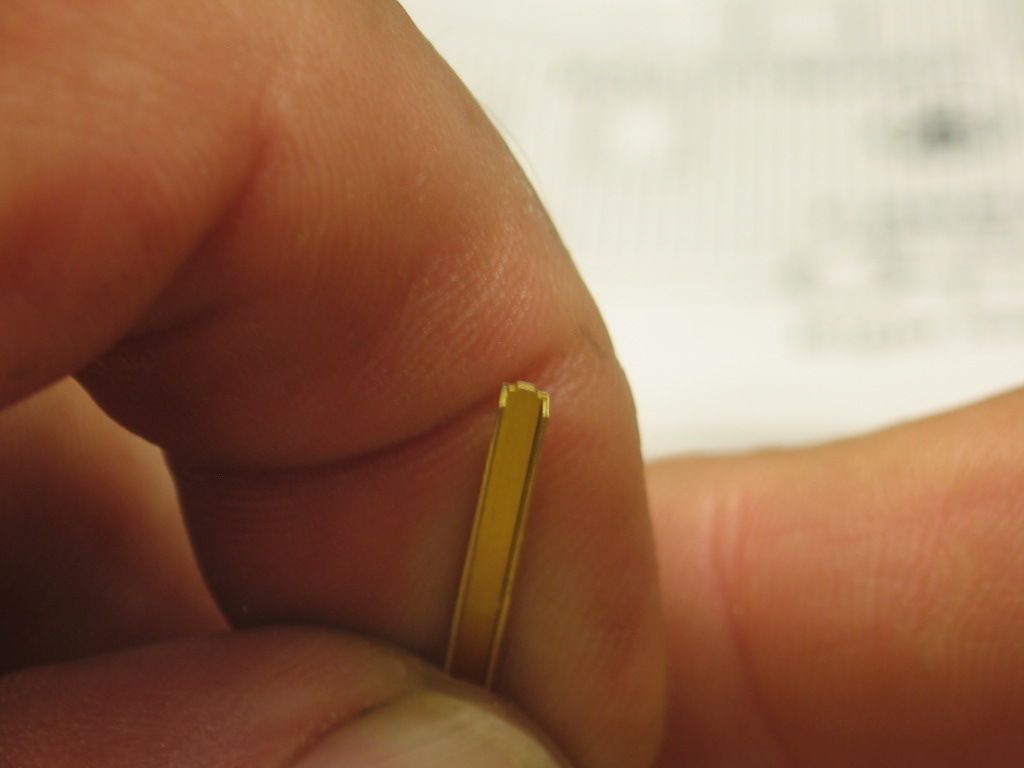

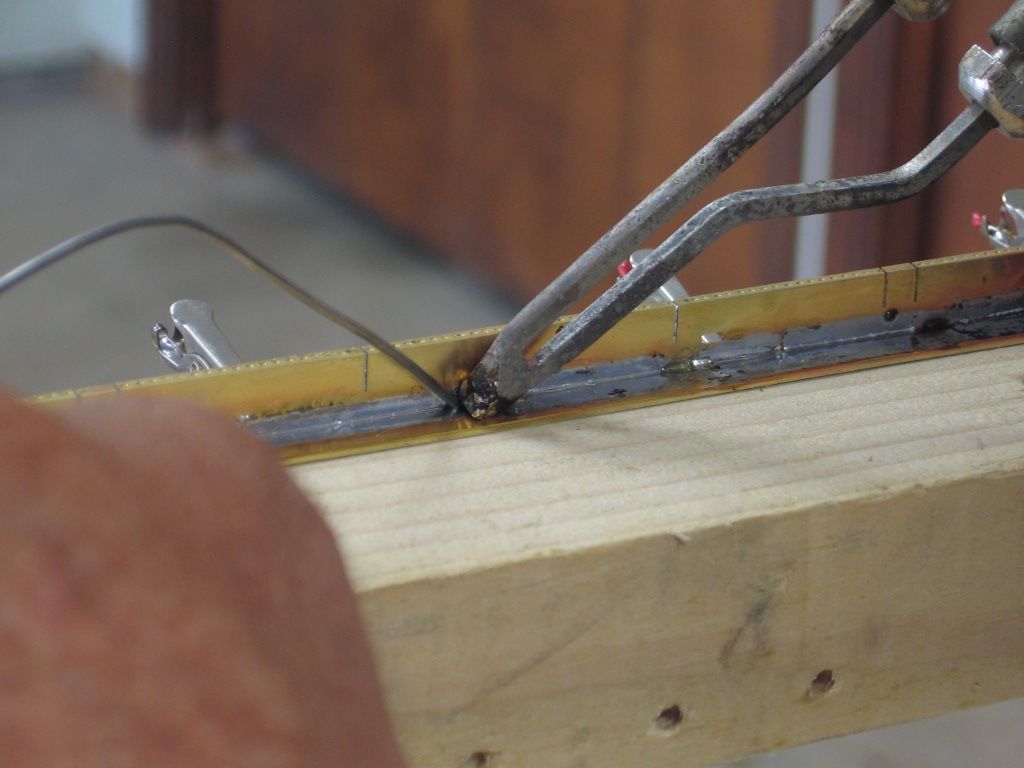

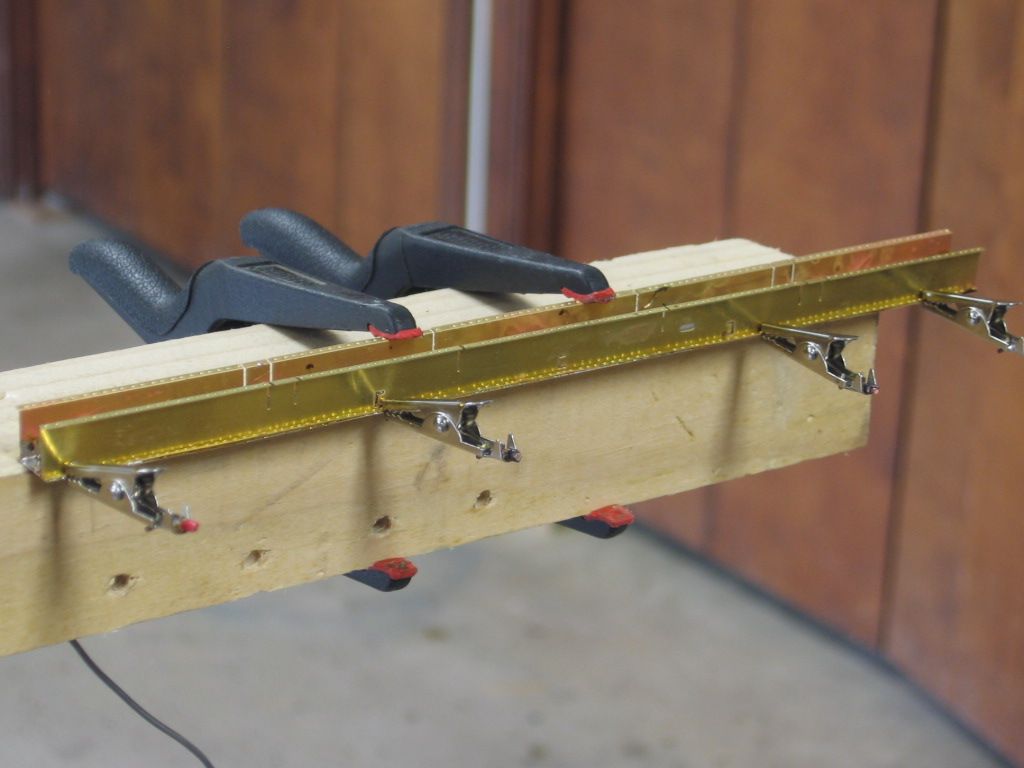

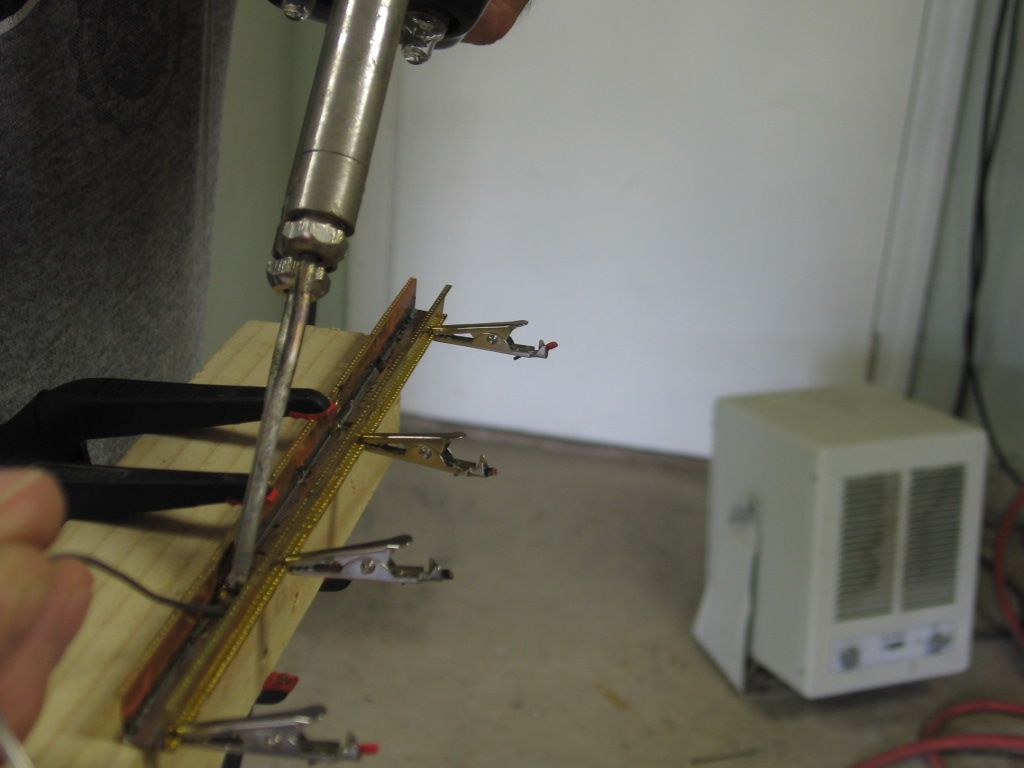

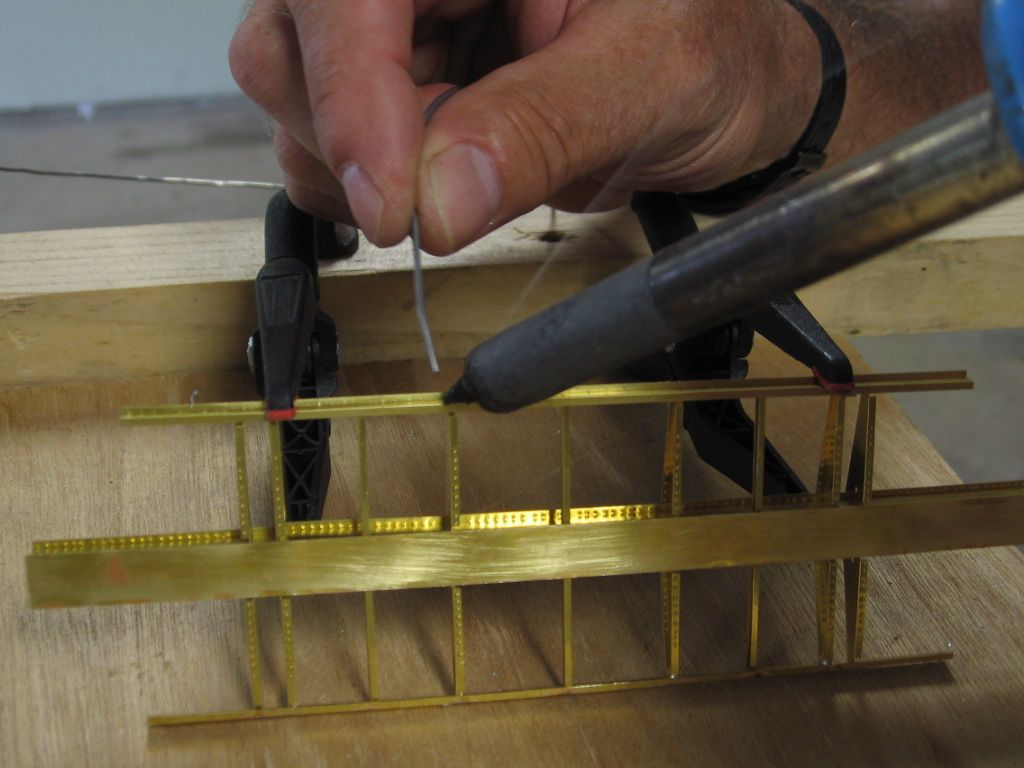

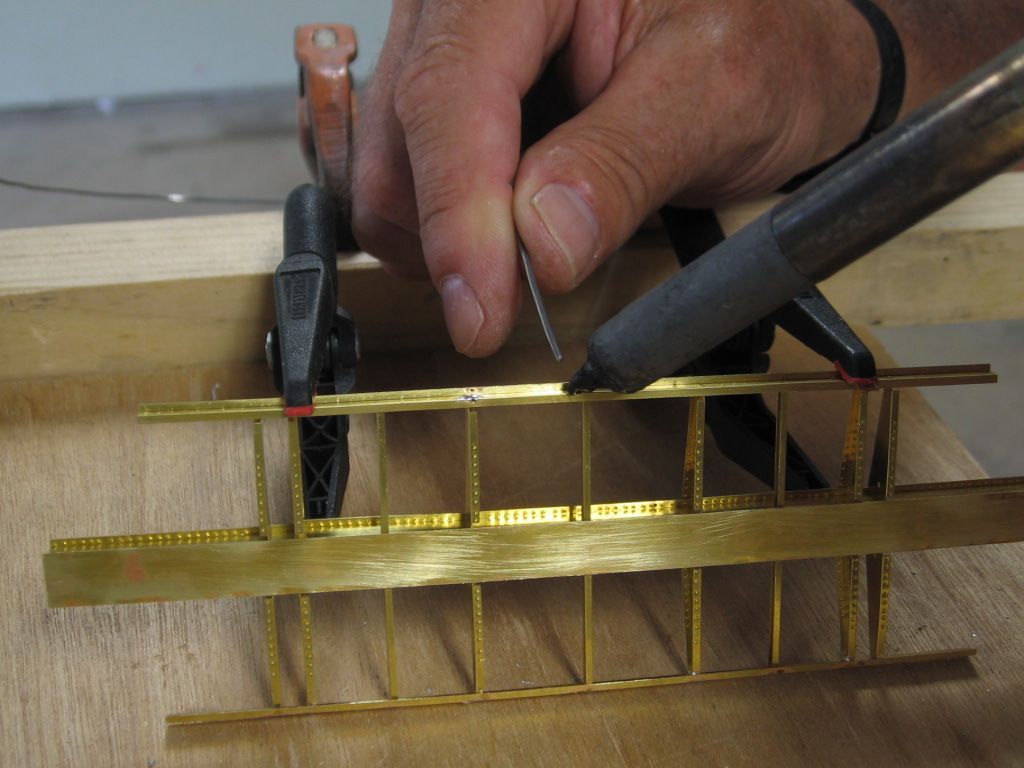

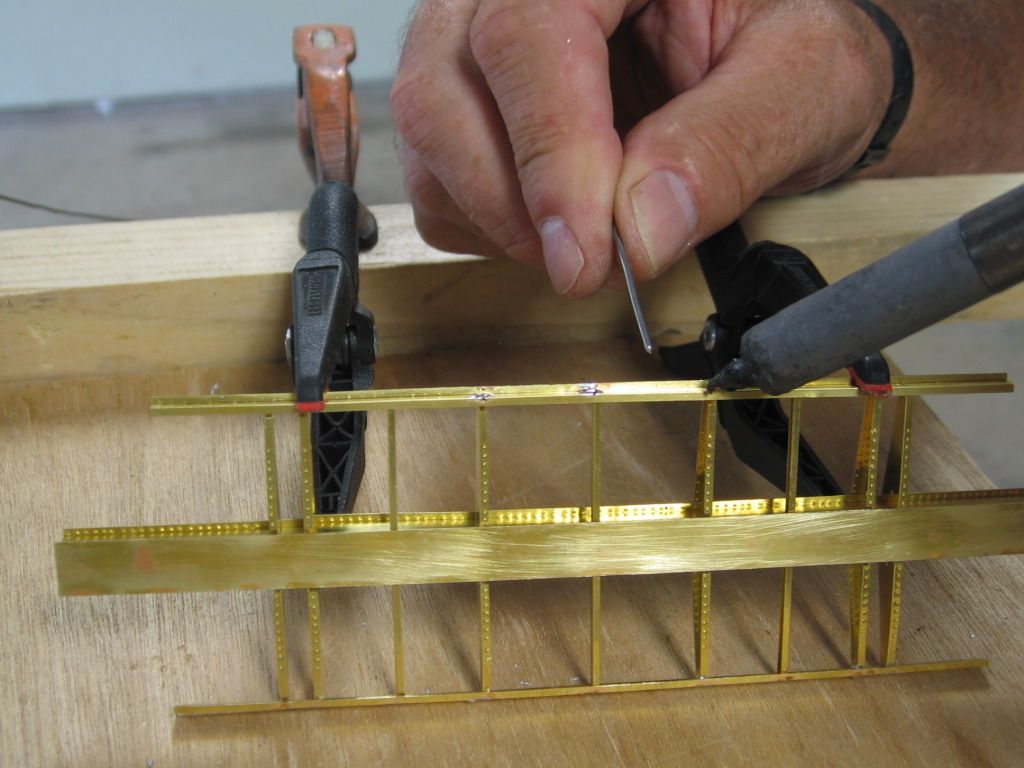

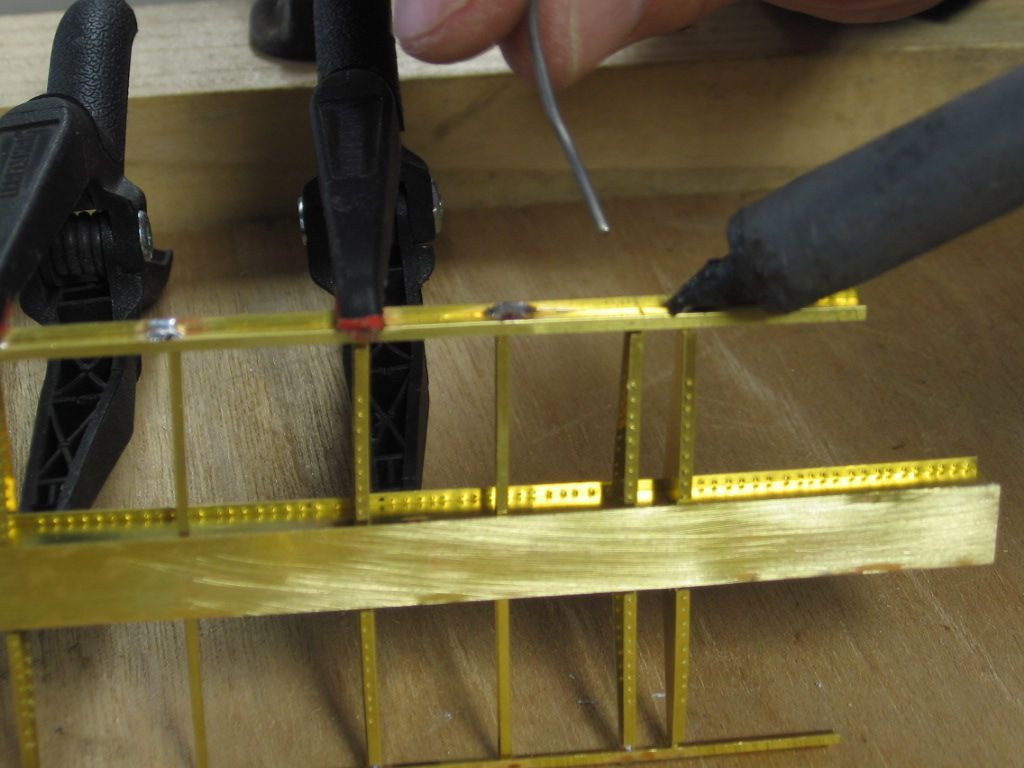

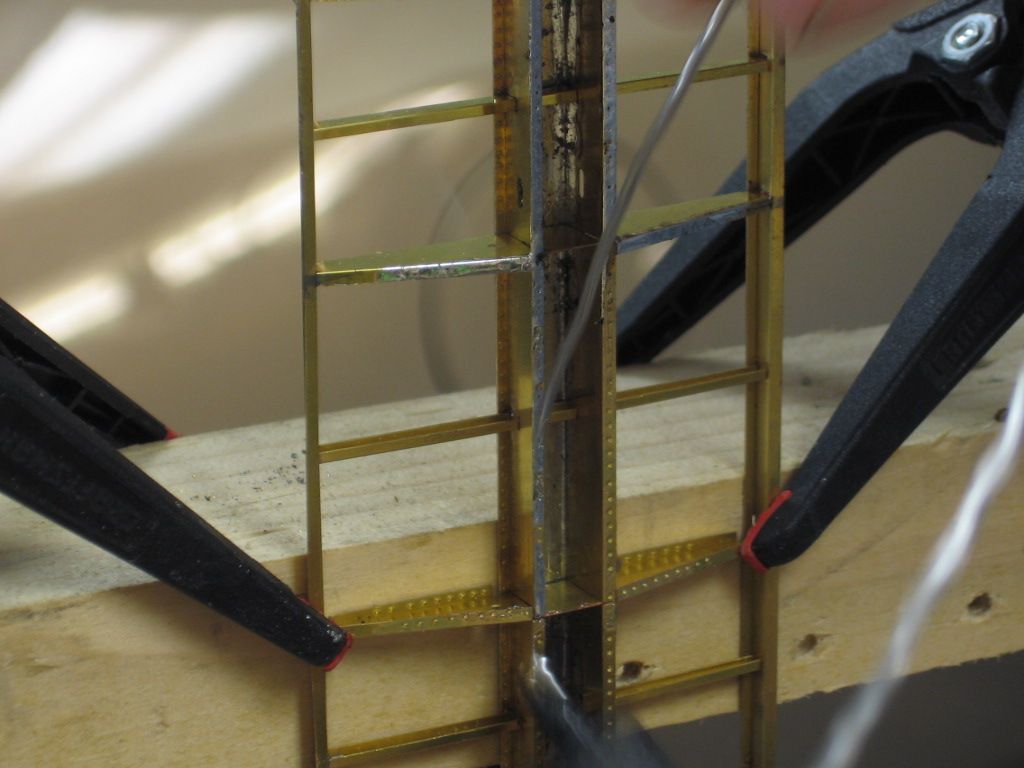

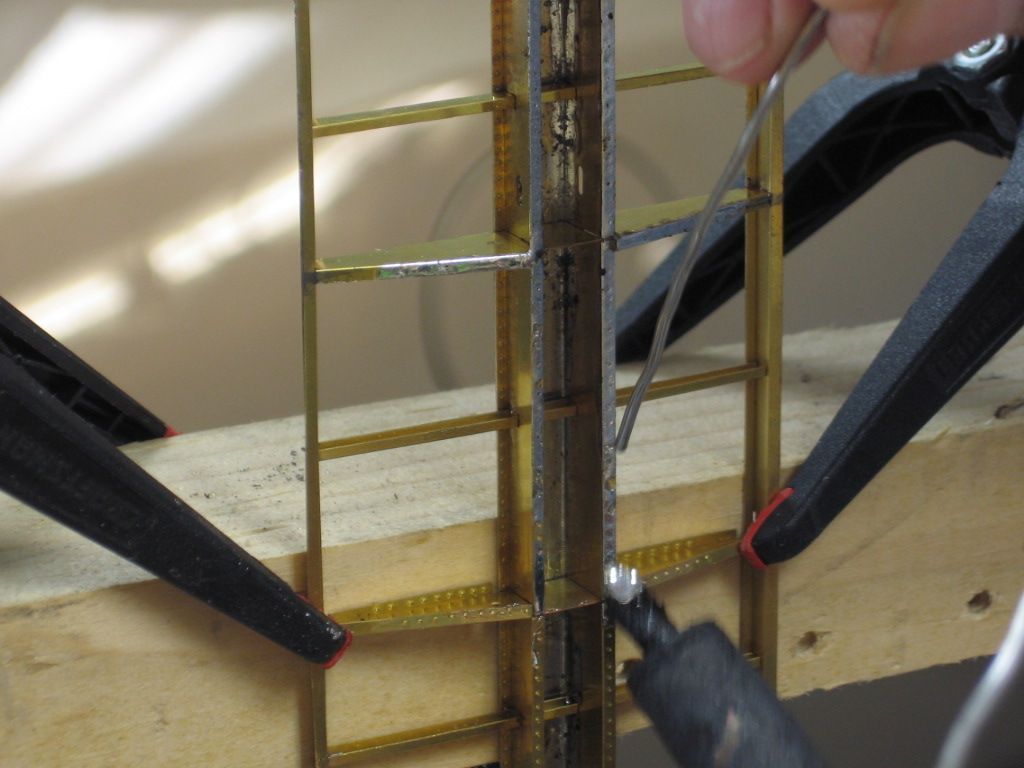

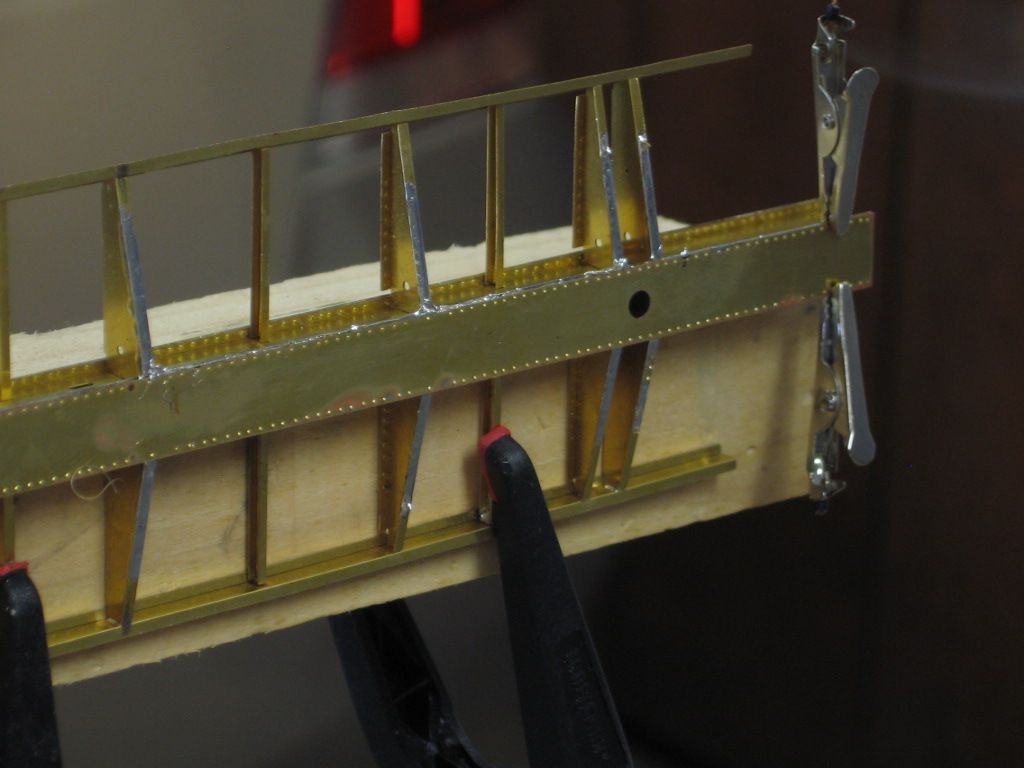

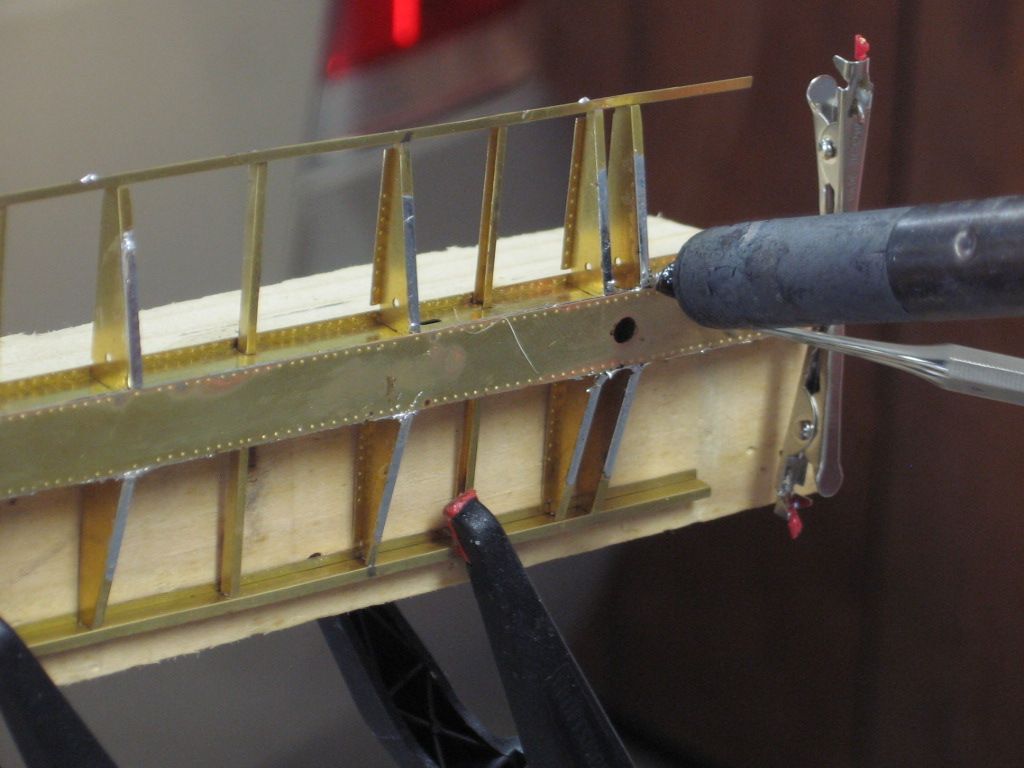

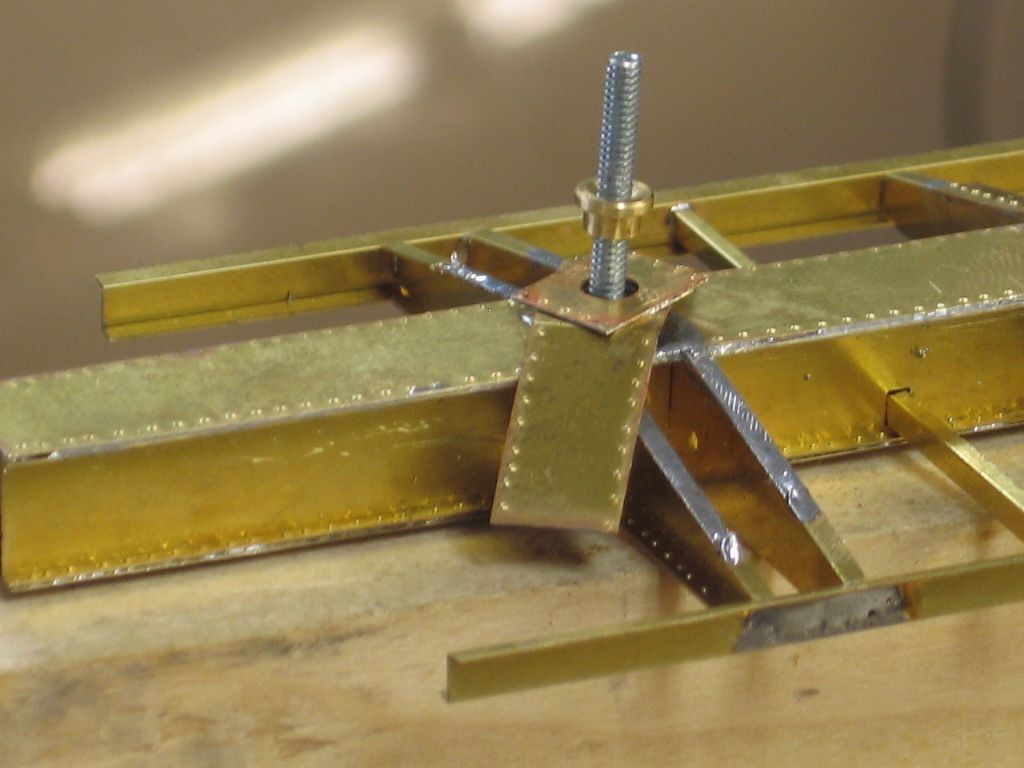

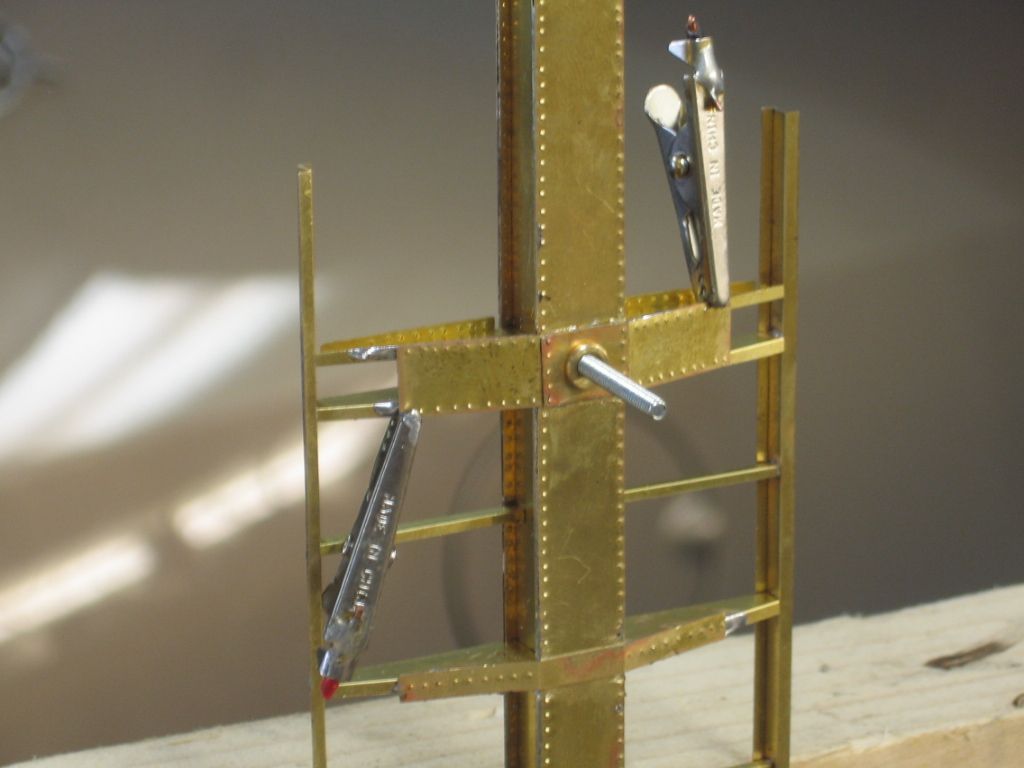

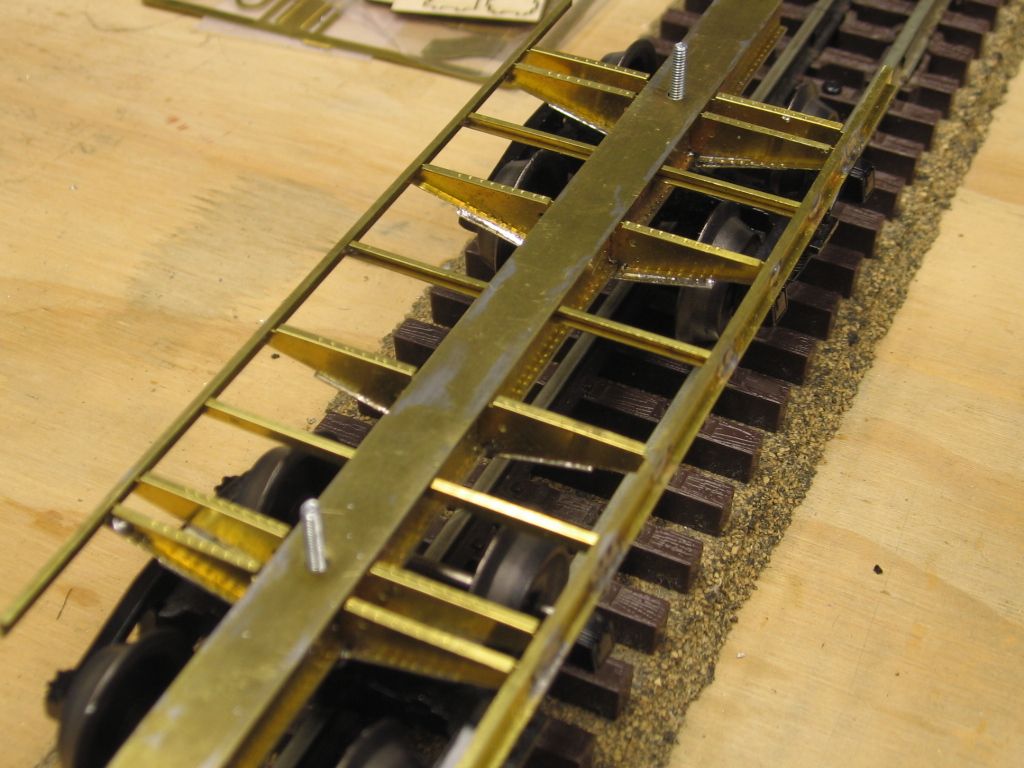

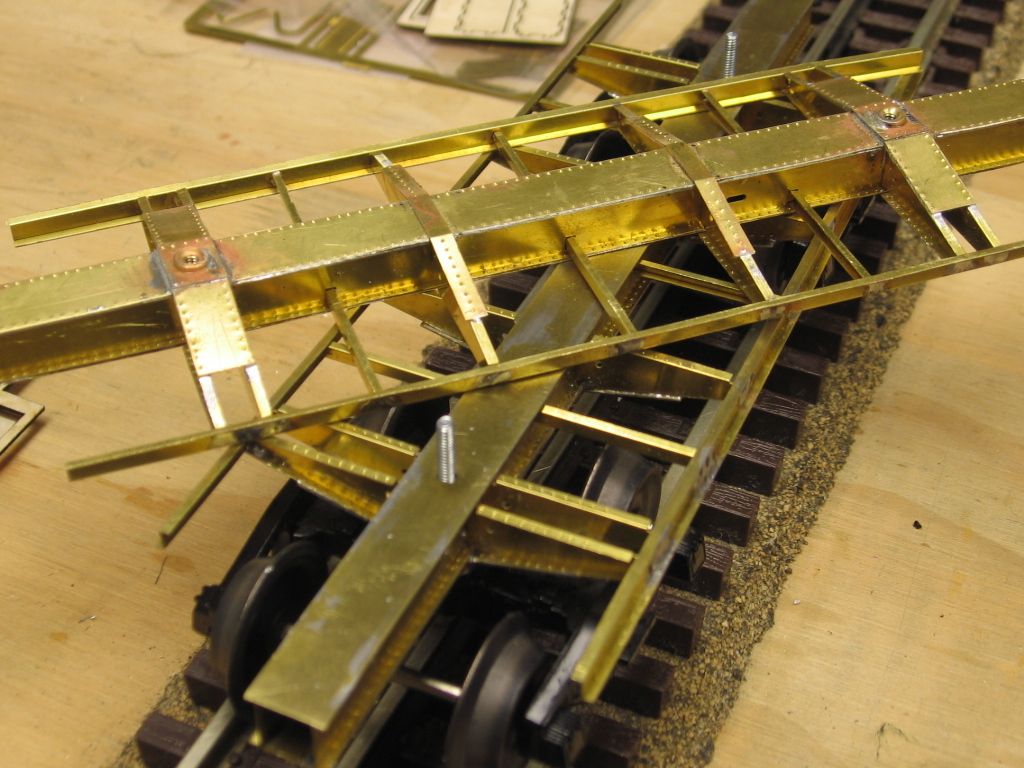

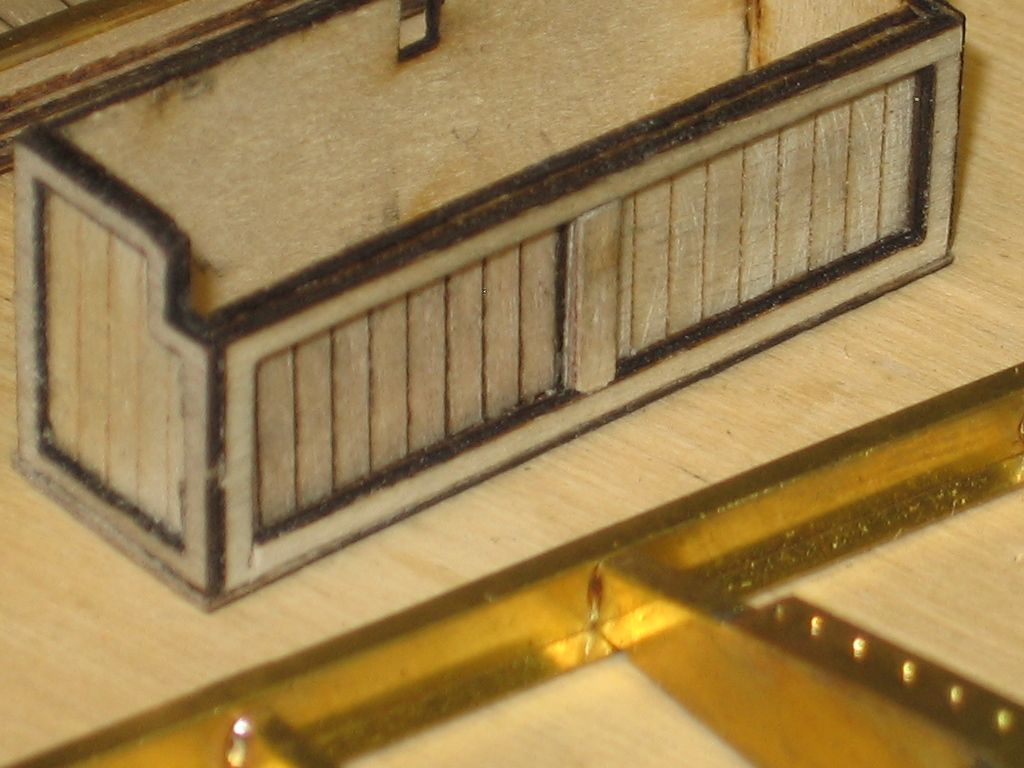

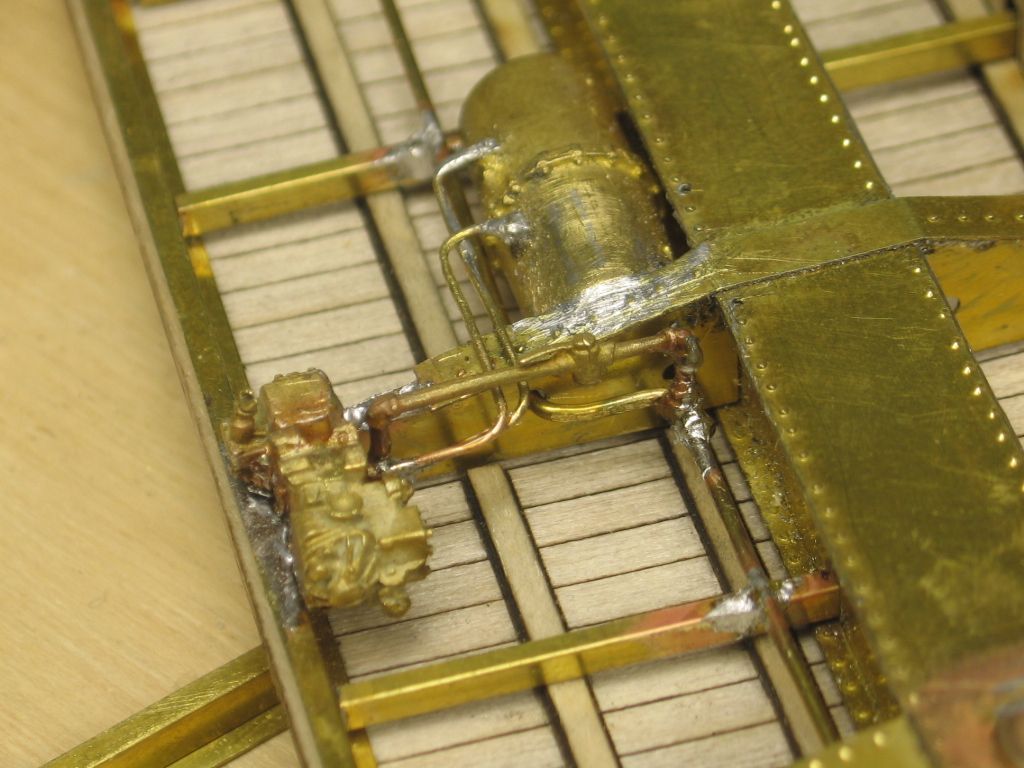

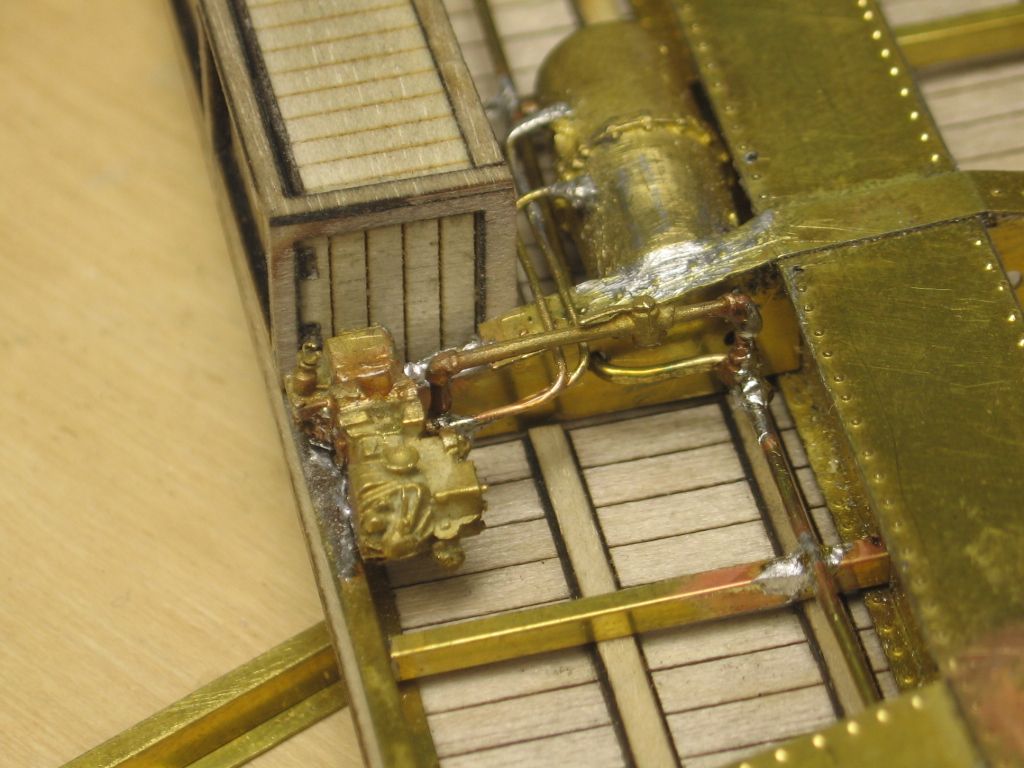

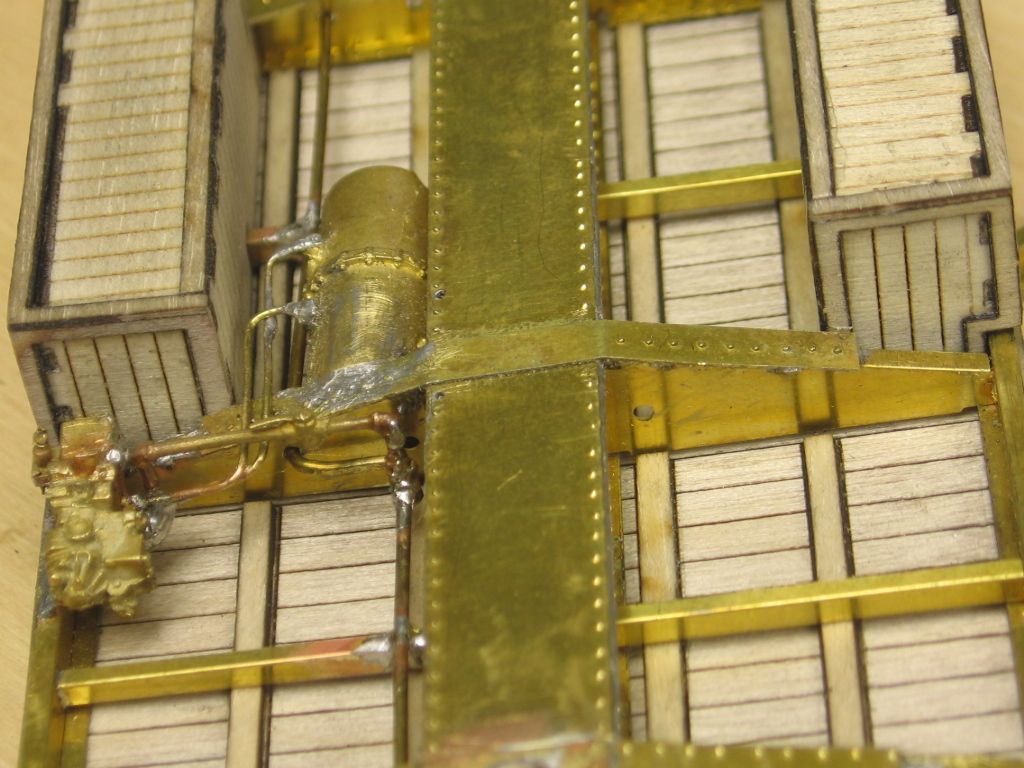

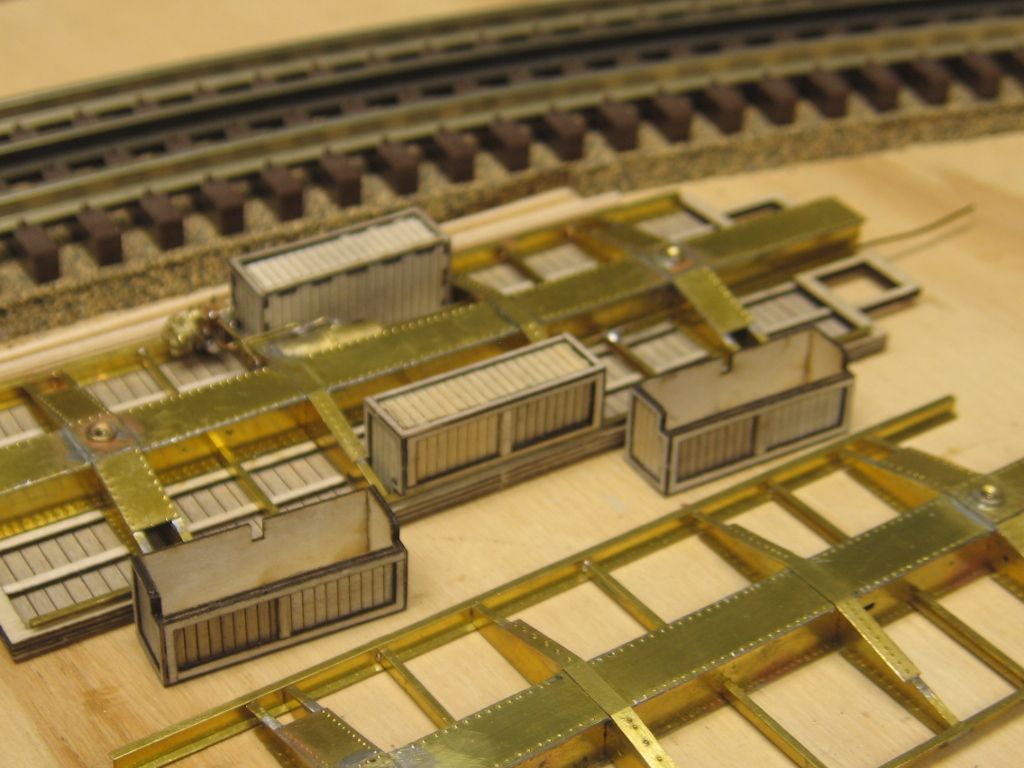

The brass parts in the kit are an etching or sometimes referred to as chemical milling. The process starts with me producing an Auto Cad drawing of the parts as you see them in the model. I produce one drawing for the front and one for the rear. The areas I want etched away are filled in solid on the drawings. The drawings are then emailed to my etcher. They review them and then produce a film positive. The film positive is produced by a laser scanning over light sensitive film. A brass sheet of the thickness is cleaned and coated with a resist material which is light sensitive. The front and back positives are laid on top of each other and tapped together in perfect alignment to form the tool. After this the coated brass sheets are inserted between the positives of the tool and exposed to high UV light which fixes the resist material. After this the brass is washed and any of the resist material that was not exposed to the light will wash off. The brass sheet is then exposed to an etching solution to eat away the exposed brass. There are two methods to do this, one involves dipping the brass sheet in the chemical and the other runs the sheet through a spray bath of chemical. I call this machine the car wash. It takes about 1-2 min to run through this machine. When the sheets come out they are washed and cleaned. The process is accurate to plus or minus .001 inch in thin sheets. As the sheet thickness goes up the undercutting affects the tolerances. In addition you need 125% of the material thickness to completely etch through. When you put your frame together you noticed that the .010" brass bolster diaphragms were loose in the slots. This is because I need to make the slots .012 wide to completely etch through. I initially tried to etch the rivets but that requires another tool and pass through the car wash. I was not happy with the way the kits went together. In addition that method created other problems in the design of the frame. The method I use gives the best control over bending and finish dimensions of the folded parts. The little holes for the riveting was a trick I picked up from the English. They love these etched brass kits. On your Sensi Press dull the point of the male die just a little and you will minimize the chance of poking though. The first etcher I used could not control this process but the current one (I have been using them since 2008) does an excellent job of quality control. When I punch the rivets I use the small holes to locate the point of the male die and then punch the rivet. The idea of the small holes is to space the rivets for you.

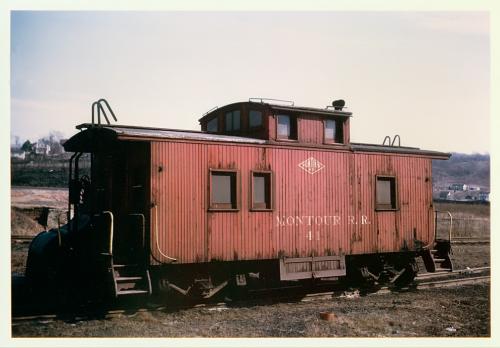

You are doing an excellent job on the kit and I like your photos. Keep taking photos as you go. I would like to then put a gallery on my web site under How To Build Our Kits. I will call this Michael Thompson builds a Montour Railroad version of our B&O Caboose.

It's nice to see people having fun building the kits. They make well detailed models and all the engineering is done.

Talk to you soon.

Glenn

Mullet River Model Works

118 Huson Ct. Plymouth, WI 53073

PH 847-308-5378

A question, does the etch resistant coating effect painting???