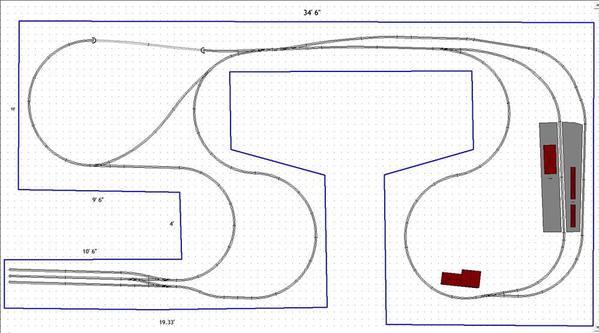

hey guys i have some questions about my layout that im putting outdoors. yes i know its asymmetrical thats part of the charm.

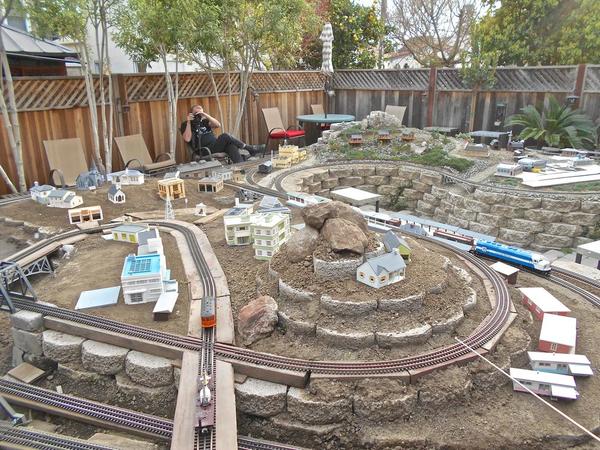

im using atlas 3 Rail Nickel Silver Track on the whole layout, min. curve O72, 35'x18' area, with 2 reverse loops and a yard, with a two Platform station on the north side, a tunnel, and the rest im just playing by ear. im planning on using mth trains in the future, and i plan to use the MRC Prodigy Pro Elite 10 Amp dcc System to run them (only two at a time) i need some recommendations for powering this big layout. if i need any more power, some uv treated/treatable buildings and accessories. do you guys have any suggestions on what i should do?. also if there are problems with my layout that you want to address to me other than the rails being too narrow for outdoors, or not to build outside, please let me know. :-)