Silly question, Since Lionel does not make O54 curves, is there a way to build a compound Fastrack curve to get to 054 radius? I just bought a new loco that requires 054 curves. I have a ton of Fastrack, but looking for options on this. Appreciate any help! For more context - I have an existing 5x10 christmas layout/board that I'd like to modify, in order to run bigger locos.

Replies sorted oldest to newest

Forgive the obvious question, if you modify and add to the width, 060 fastrack would work?

It is a silly question and in the first sentence of your post you are confusing diameter and radius. O54 curves mean the circle will be 54" in diameter. A 54" radius would create a circle with a 108" diameter. Go repeat 6th grade math and post your findings. ![]()

You need to use a full circle of O60 curves or switch to another brand of track which has flextrack in their line.

That being said, depending on your engine, it's possible it would run on a circle with some O48 sections mixed in.

-Greg

Would be hard to increase the width of the boards as 1) my building skills suck, 2) The existing layout is comprised of two 5x5 sections of foam that connect around the base of my christmas tree, and 3) if I put some sort of plywood underlayment to glue the foam to, then the layout becomes really hard to move around and hard to fit up and down the stairs. May have to look at Atlas or Gargraves and go O54 to create the oval in order to fit.

You can mix and match, however, you may have to go to 1/2 and 1/4 track sections.

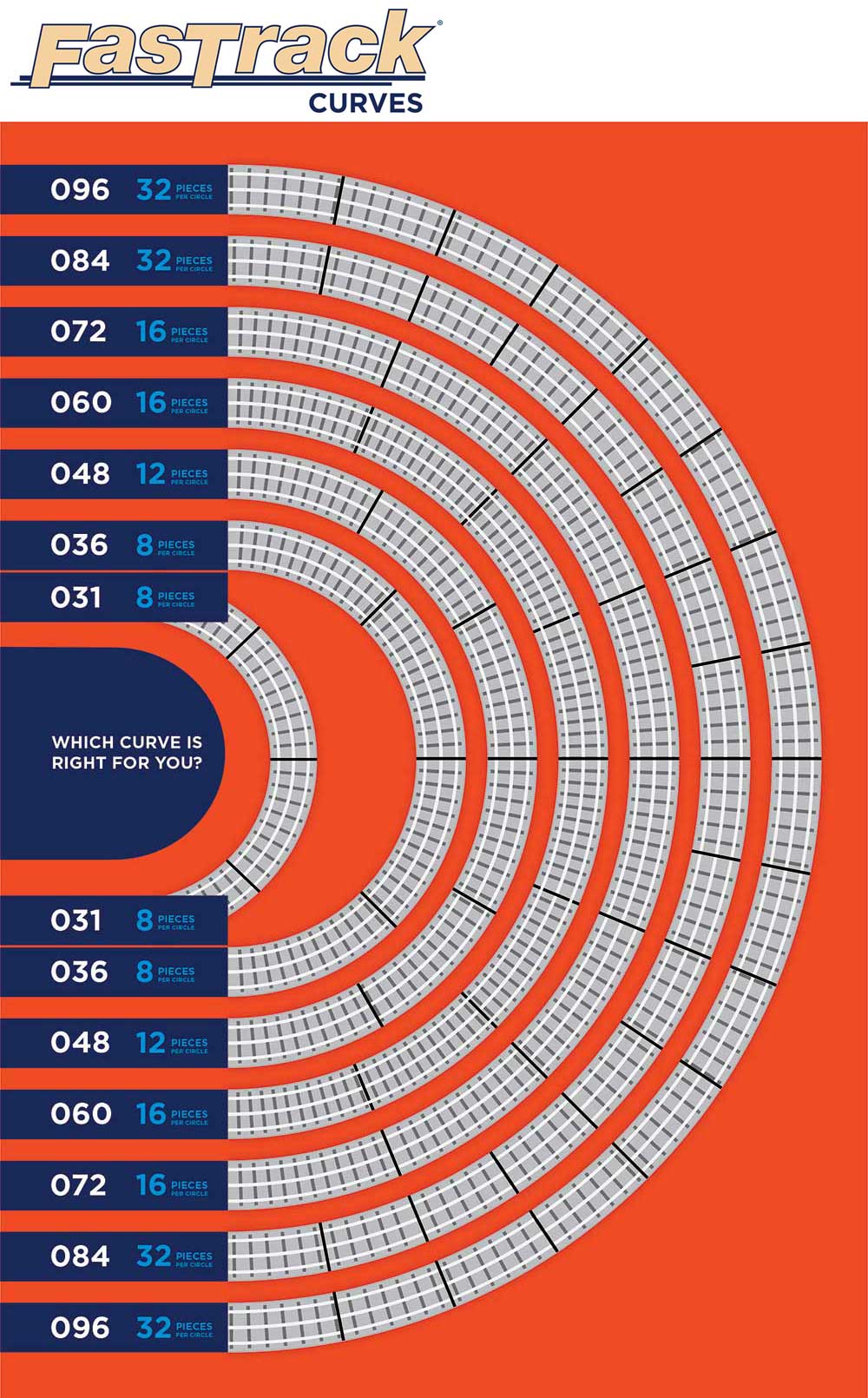

Again, an O60 curve is 16 pieces, O48 is 12.

They make an O48 half curve piece 6-16834 FT O-48 1/2 Curve

So to make the half curve at the ends of the table 5X10 feet, use 4 pieces of O60, and then at each end, the easement from O48 is 1 full piece, one half piece of 048.

I did a test using RR Track.

5x10 layout

Again, the curves at the end. The middle of the curve is 4 pieces of 060, and 4 pieces of O48, however, 2 of them are 1/2 curve O48.

However, you can change that order and get a long skinny version that starts with O60 curves, and then O48 in the middle.

Straight inventory changes slightly.

Attachments

You need 180 degrees in a 1/2 circle.....that would be four O60s (22.5 degree times 4) and three O48s (30 degrees times 3).

Clearly this shrinks the width so that you can fit it on a 60" wide table........but the question remains.....would your O54-requiring engine be able to navigate it.......

Peter

@Putnam Division posted:You need 180 degrees in a 1/2 circle.....that would be four O60s (22.5 degree times 4) and three O48s (30 degrees times 3).

Clearly this shrinks the width so that you can fit it on a 60" wide table........but the question remains.....would your O54-requiring engine be able to navigate it.......

Peter

In my experience, yes, quite a few O54 engines actually navigated 048 Fastrack without easements. In fact, I've even run a shay on one, but it had to be faced the correct direction.

And yes, in the latter example I posted, i could and should have forgone of the 1/2 48 curves and just used 3 full O48 pieces. Good catch, I was just making it the same pieces could be arranged either way for maxing the absolute width of the table out. In other wors, ease from a wide turn into a sharper turn, or go from a sharp turn and ease up to a wider turn, and then back down before going straight. I do not know for sure which works better with a given engine.

pbuff,

Why not just add an additional strip, along one of the long sides, for the O-60 track width? Tree cutout, if it already exists, doesn't have to be centered.

Or, if you're buying the larger track circle anyway, you could go O-72 which can handle most engines.

Dave

@Vernon Barry posted:In my experience, yes, quite a few O54 engines actually navigated 048 Fastrack without easements. In fact, I've even run a shay on one, but it had to be faced the correct direction.

And yes, in the latter example I posted, i could and should have forgone of the 1/2 48 curves and just used 3 full O48 pieces. Good catch, I was just making it the same pieces could be arranged either way for maxing the absolute width of the table out. In other wors, ease from a wide turn into a sharper turn, or go from a sharp turn and ease up to a wider turn, and then back down before going straight. I do not know for sure which works better with a given engine.

Using the wider version and the combined O-48 and O-60 pieces, it certainly looks to the naked eye that the diameter of the curve is substantially increased above 48"; probably enough to run the engine in question without issue.

My own anecdotal experience is that, in general, my trains do not like to be squeezed down in curvature size in the middle of a curve, so I would always opt for going from sharper to wider and then back down, but the OP's mileage may vary.

pbuff,

How are you joining the two 5ft squares now?

Dave

The way I built it was, I cut a square out in the middle to go around the christmas tree base, then push the sections together, and including joining the track (which is a giant Pain in the A because I don't have a lot of room behind the tree by the front window). This year I was thinking of nailing the track sections down, but not trying to join the track pins, and instead make sure each side had its own power drops. Pics for reference.