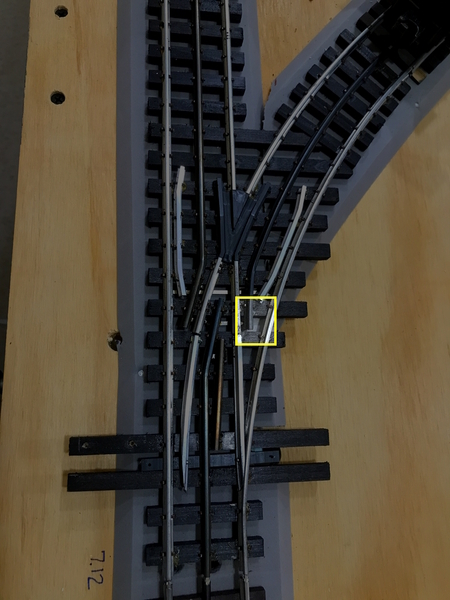

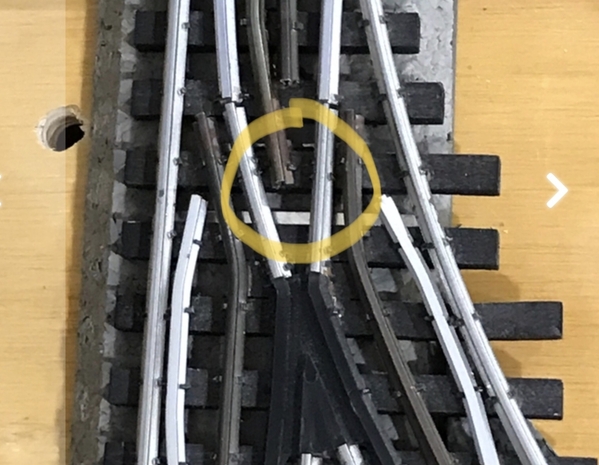

I’m with Dave on this one, …..most of the time I get asked about this particular problem, it’s a diesel, and it’s fat wheels designed around tighter curves for marketing. I’ve circled what I would look at first. The blue arrow represents the the fat wheel coming through and getting oober close to the power ……you can confirm this by looking for witness marks on the wheels and the track. I’ve trimmed that power rail on stubborn offenders to get the backside of a wheel to pass by it without rubbing…..

Mike also brings up a good point about pickup rollers bridging a section,….I’ve seen that more than once, especially if the roller is super wide, like older Williams pieces have.

The best procedure I’ve used to diagnose this issue is to set the engine right where it croaks, cold with no power and tilt the engine from side to side observing what’s touching and what’s not touching…….a continuity tester on your DVM can be a friend here too,

Pat