Hi Timothias,

Use ramps where you want make it appear like rock or an earthen incline. 1/4"ply is fine. The nominal is like 3/16" or 5mm. Cut one end of the supporting block on a bevel to match the slope of the incline. Then, the wood sits flat on top. You'll never get the splinters out of you after working with OSB.

many do not put deck where the inclines will be. Just attach the supports to the framing crossmembers.

I am not a big fan of homosote. It does provide an easy surface to attach layout objects. It is messy to cut, drill or generally work with. You must seal it with 2 or 3 coats of cheap latex. It will absorb humidity.

The sound absorption factor of homosote is minimal for FasTrack. Carpet padding works best under FasTrack The thick upgrade type. Just a little wider than the width of the track. Use ballast to hide it.

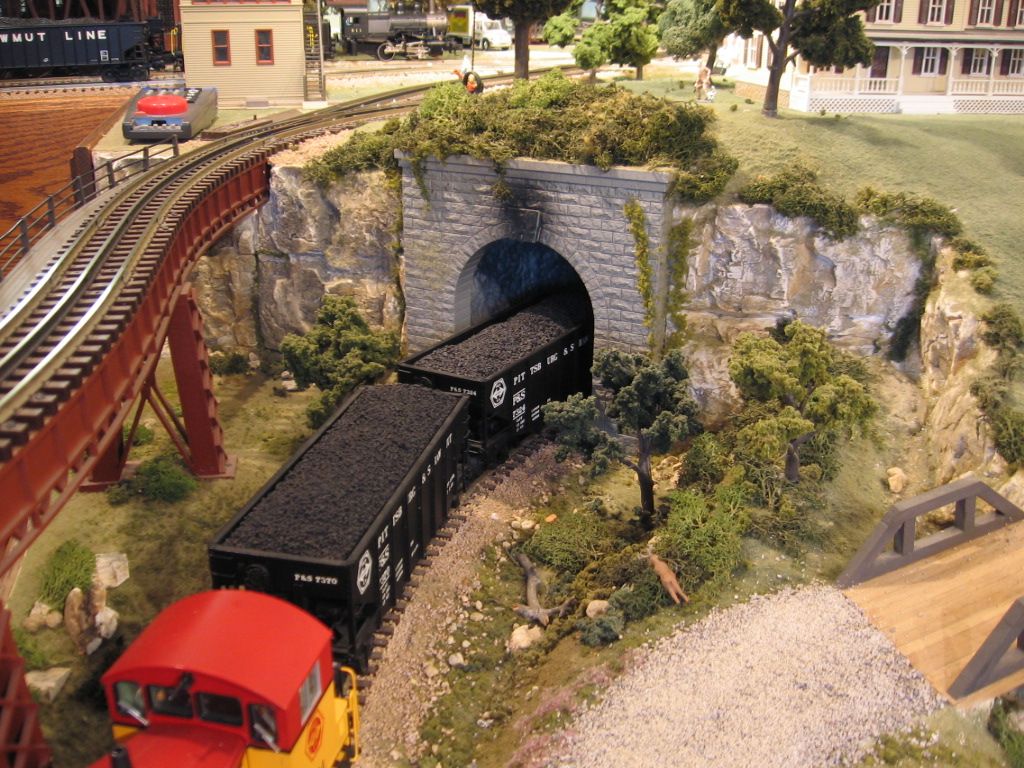

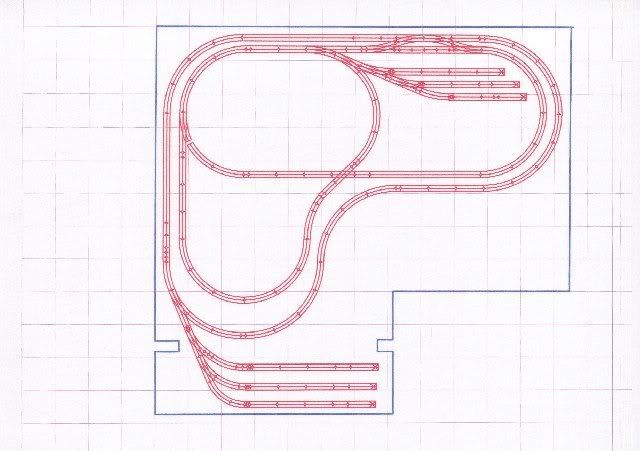

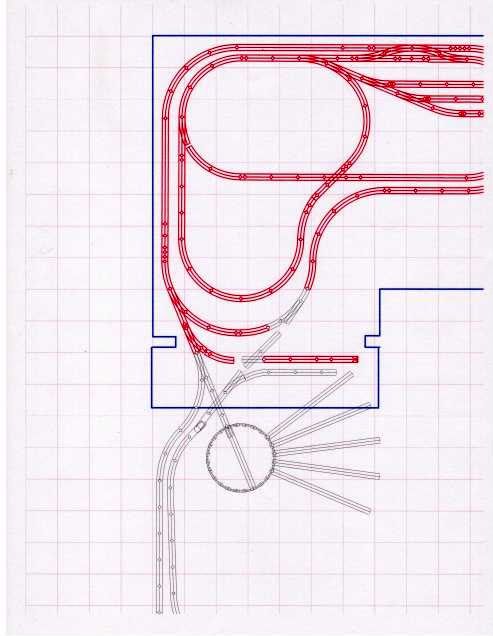

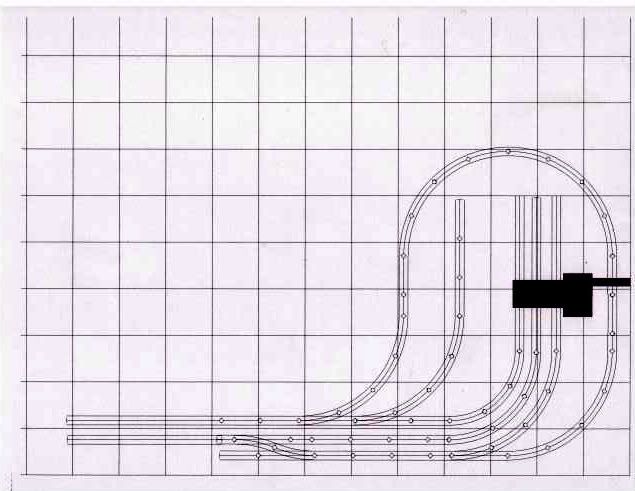

Check out this build thread for some nice techniques Hidden Pass Junction RR