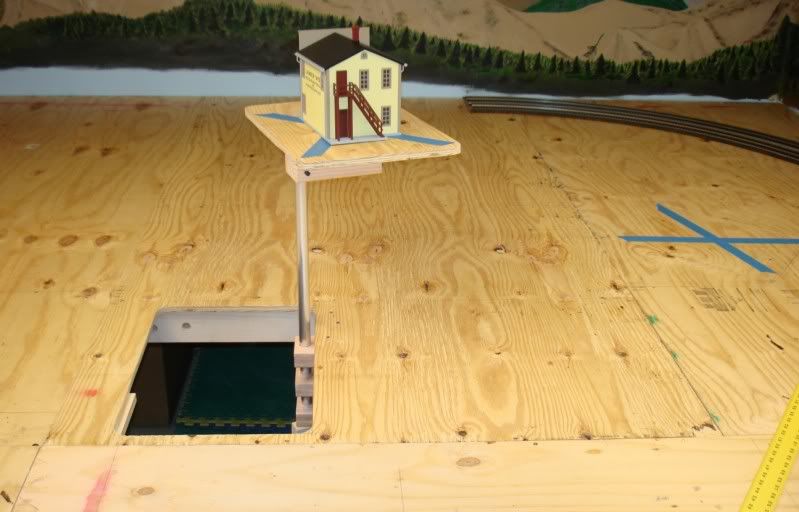

Finally started on the layout! But first, following your recommendations, I painted portions of the backdrop. I guess I am more of a carpenter than a painter, but it this will do for now. A couple of shots before starting the fun part.

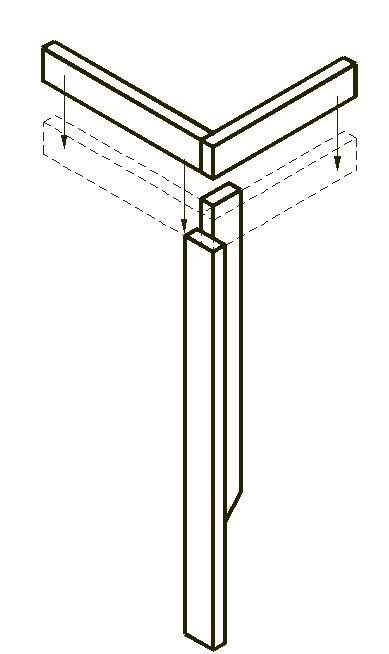

A new leg design so the frame rests on the legs instead of on the screws that fasten the leg to the frame. (BTW - I just noticed that the camera distorts some of the images - the legs ARE SQUARE to the frame when done!)

Saturday:

Assembling one of the cross braces –

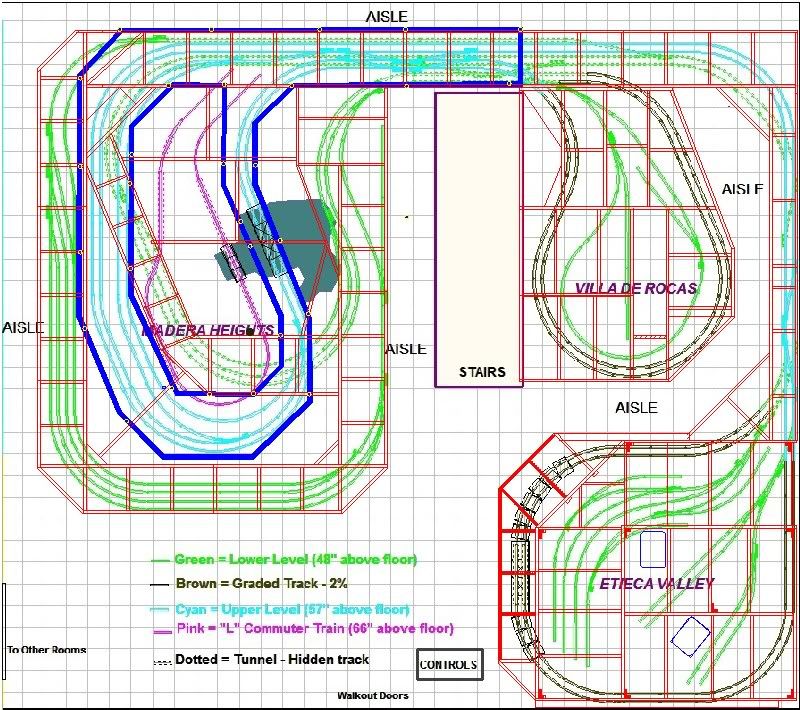

An afternoon’s worth of work - how it looked Saturday night (12' x 12' section):

A now to continue . . .

Alex

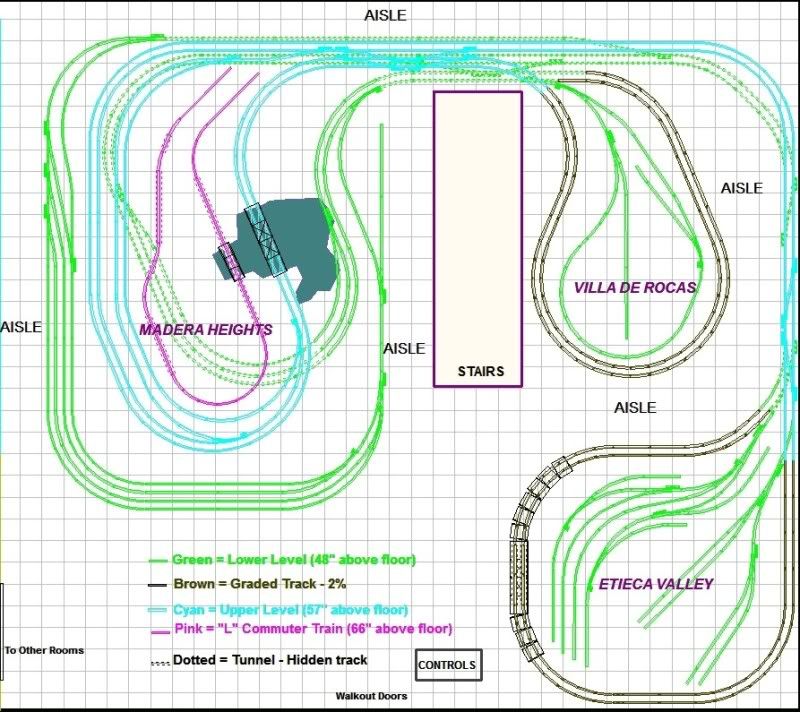

Original Post