Alex,

I have your posts and refer to them daily. Your layout is quite beyond belief and one of the best I've ever seen. Your precision is unmatched. Also, I am expanding my table layout up two levels and you have already given me several ideas.

Can you please take some time to answer some pretty fundamental questions? Please forgive me in advance for being so dumb.

1.) How do you get any train to pull 50 cars around curves without them derailing? Is it the larger radius curves or are they heavier/modified cars?

2.) Can you please explain some of those gorgeous fences: Did you make them all? Did you cut all those tiny slats on the wooden ones?Where did you get the chain-link fencing? Did you make all the track railings yourself? How did you get them so perfectly aligned? How did you get those post-in-the ground railings to have such straight wires through them?

3.) Where are you getting all those unique figures from? I've never seen so many different people poses.

I have lots more, but....

Jerry

Hi Jerry! Thanks for your comments -

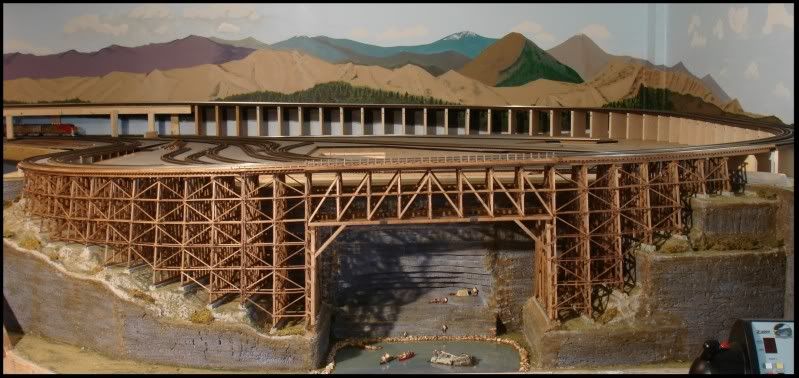

1) Pulling 50+ cars: As you mentioned, the 1.9% - 2.0% grades and the Ø108" and Ø99" curves must have a lot to do with it. I do not modify the cars, but try to place the heavier ones closer to the locomotives. The Big Boy (MTH and undoubtedly the Lionel VL) has pulled 50+ cars effortlessly, and I know that it could pull more. The MU diesels, whether MTH or Lionel, have also pulled a similar number of cars. I also routinely and successfully push trains with 30 cars up the grades, very slowly. One time, however, while pushing a train with 20 auto-racks plus 10 more cars behind them, one (and only one!) of the auto-racks was pushed out of the way while in the tunnel that is at the end (or start) of the grade. Evidently, the cars behind the outcast car rolled on their own and coupled to the rest of the train. I did not notice this until much later when another train on a parallel track hit the outcast car, and the sound caught my attention. I wondered what had happened, and then saw the car. I had been video tapping all of this, and during playback I was able to see a train with 30 cars, and after the operation, only 29 cars were present. The auto racks are very light.

2) Fences: The wooden slat fences are Model Power (bought) and painted. The chain link fence material is from Dennis Brennan fence kit, which I modified somewhat. The track railings are homemade out of Ø1/4" wooden dowels and Ø0.021" stainless steel wire rope, which would be close to Ø1" in real life. I drill holes through those dowels (after doing a few, it becomes easy), and thread the wire rope. I used the same concept to add rails to the Menards Coil Car:

I then drill holes on the QuietBrace (similar to Homasote) and 'plant' them.

3) Little people: I have several brands, but most are Woodland Scenic Accents figures. And I do have a few Arttista figures as well.

Glad to answer any questions you may have; after all, that is how I learned - by observing and asking in this great forum!

Alex